ZJQ200 30 45 погружной шламовый насос для копания речной Ил песок

- Категория: >>>

- Поставщик: Shijiazhuang Naipu Pump Co. Ltd.

Сохранить в закладки 60569061210:

Описание и отзывы

Характеристики

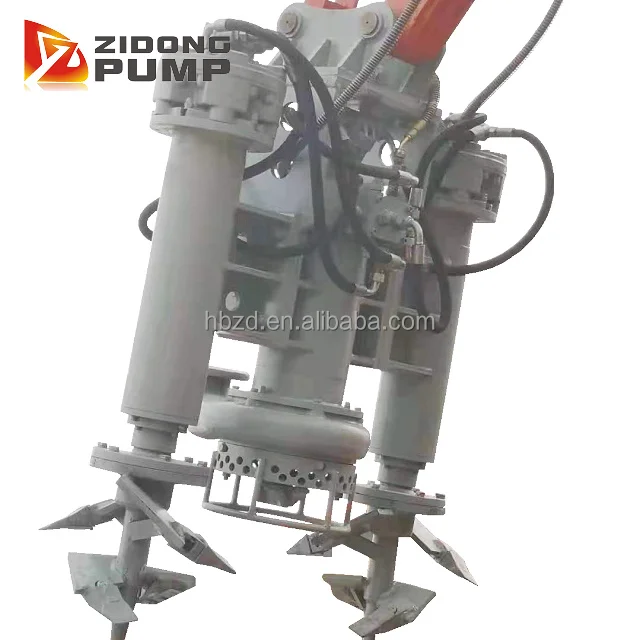

ZJQ200-30-45 Submersible Sludge Pump for River Mud Sand Dredging

Submersible slurry pump

ZJQ submersible centrifugal slurry pumps are mainly used to pump high-hardness, strong-corrosion and high-concentration liquids that contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones and etc.

Application Condition

1— Power: 50/60HZ, 380V/460V/660V, 3-Phase.

2— Medium Temperature: Max. 40°C and without explosion gas.

3— Slurry Concentration By weight up to 60%.

4— Max submersible depth: <20m

Min submersible depth: >1m

5— Type of installation: Vertical (recommend) or as

customer’s requirement

6— Continuous operation

Advantage

1— Submersible work Without influence of suction head.

2— No assistant vacuum pump, save your invest

3— No noise, keep the silence of your work station

4— With agitator, no need extra stirring devices , more convenience

for operating.

5— It need not to build pump house.

6— Directly works on the surface of the slurry, with more efficiency

to deliver slurry.

Submersible pump construction drawing

Main part number at the drawing

1. Power cable 4. Motor cover 5. Thermal sensor 6. Stator 7. Rotor 8. Lower bearing 9. Float switch 10. Oil chamber 11. Mechanical seal | 12. Oil sealing 13. Spacer sleeve 14. Casing cover 15. Casing 16. Impeller 17. Wear ring 18. Strainer 19. Agitator 20. Impeller cap 21. Base plate 22. Control cable |

3. Materials of construction

| IMPELLERS | CASING | AGITATOR | SHAFT | WEAR RING | EXPELLER | CASING COVER | SPACER SLEEVE | OIL CHANBER | OHTER PARTS |

Standard | KMTB Cr26 | Cast Iron | KMTB Cr26 | St. St. 316 | KMTB Cr26 | KMTB Cr26 | KMTB Cr26 | St. St. 316 | Cast Iron | Cast Iron |

Specification

• Size range (discharge) 1" to 20" 25 mm to 500 mm

• Capacities to 22,000 gpm to 5,000 m3/hr

• Heads to 426 ft to 130 m

• Pressures to 300 psi to 2,020 kPa

Type Notation

ZJQ50-26-11

50 Capacity(m3/h)

26 Head(m)

11 Power(kw)

J With Agitator

L With cooling jacket

Submersible pump performance parameters

No. | Type | Outlet dia. mm | Capacity m3/h | Head m | Power kw | Speed r/min | Max. Dia. Of granule mm | Weight Kg |

30 | ZJQ60-46-30 | 100 | 60 | 46 | 30 | 980 | 21 | 550 |

31 | ZJQ70-38-30 | 100 | 70 | 38 | 30 | 980 | 21 | 550 |

32 | ZJQ75-45-30 | 100 | 75 | 45 | 30 | 980 | 21 | 550 |

33 | ZJQ100-35-30 | 150 | 100 | 35 | 30 | 980 | 21 | 550 |

34 | ZJQ108-30-30 | 150 | 108 | 30 | 30 | 980 | 21 | 550 |

35 | ZJQ150-30-30 | 150 | 150 | 30 | 30 | 980 | 21 | 550 |

36 | ZJQ200-25-30 | 150 | 200 | 25 | 30 | 980 | 21 | 550 |

37 | ZJQ250-20-30 | 150 | 250 | 20 | 30 | 980 | 21 | 550 |

38 | ZJQ300-15-30 | 200 | 300 | 15 | 30 | 980 | 28 | 700 |

39 | ZJQ100-50-37 | 100/150 | 100 | 50 | 37 | 980 | 21 | 918 |

40 | ZJQ300-20-37 | 200 | 300 | 20 | 37 | 980 | 28 | 850 |

41 | ZJQ400-15-37 | 200 | 400 | 15 | 37 | 980 | 28 | 850 |

42 | ZJQ100-60-45 | 150 | 100 | 60 | 45 | 980 | 21 | 950 |

43 | ZJQ150-35-45 | 150 | 150 | 35 | 45 | 980 | 36 | 1000 |

44 | ZJQ200-30-45 | 150 | 200 | 30 | 45 | 980 | 36 | 1000 |

45 | ZJQ500-15-45 | 250 | 500 | 15 | 45 | 980 | 46 | 1100 |

We can produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting.

|  |

|  |

Packaging details: 1. Outside package: standard export wooden cases. 2. Inner package: Stretch film.

| OEM service | Produce the pump and spare parts according to client's drawing or sample. |

| Pump slection | Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. |

| Using service | Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. |

| Quality control | Pay more attention to the quality in every process with different instruments. |

| Material service | Interchangeable metal design allow best material choice for any application. |

| After-sales service | Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. |

| Guarantee | One year guarantee for whole machine except of the wet end parts. |

Shijiazhuang Naipu Pump Co., Ltd is a professional manufacturing enterprise of slurry pumps. We have about 30 years experiences and export to worldwide countries. Our technical team consists of talents specialized in hydraulic machinery, casting, heat treatment, engineering, material science and machining. We proudly manufacture quality pumps whose parts are 100% reverse interchangeable with major brands. This means no more inventory hassles when you decide to use another pump supplier.

Submersible Pump Quality Control

| Stages of manufacture | Quality cotrol activities | Specification |

| Raw material arrival | Sampling, material chemical analysis | NPB121.1-29-1997 |

| Casting and composition | Material material chemical analysis of pump parts | NPB121.1-29-1997 |

| Casting quality inspection | NPB302-1998 | |

| Key component machining | Dimension precision inspection | NPB2105-87 |

| Impeller balancing | NPB061-2000 | |

| General assembly | Procedure operaion | NPB2103-96 |

| Hydraulic static test | NPB064-1998 | |

Performance test of pump unit | Capacity and head | NPB157-1997 |

| Vibration and noise | JB/T8097-95 | |

| Bearing temperature | JB/T5295-91 | |

| Final inspection | Packaging of pump unit | NPB0157-1997 |

| Documents | NPB0157-1997 | |

| Spare parts and accessories | NPB0157-1997 |

1. Our pumps quality has reached domestic and internaional advanced level in this field.

2. We are responsible for our products quality, if there are some quality problems after you received, we will be prmptly returned or replacement the kits.

CE, SGS, ISO9001 Certification

Похожие товары

Одноступенчатый горизонтальный Трубопроводный центробежный насос из нержавеющей стали, 304 316L, прямое соединение для вакуумного использования, химический насос

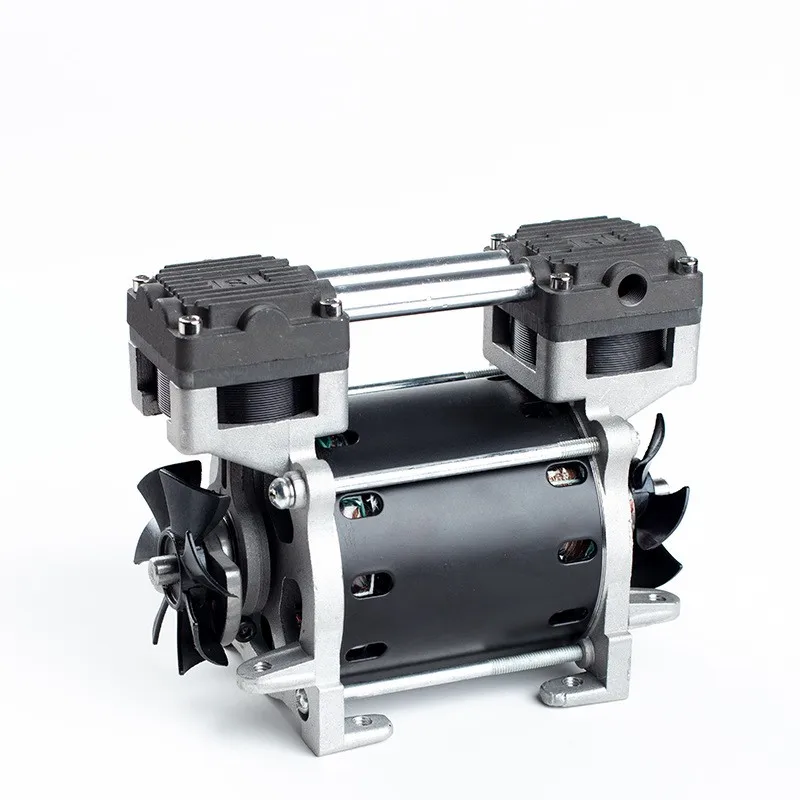

Бесшумный мини-вакуумный насос 80 Вт, безмасляный поршневой вакуумный насос, небольшой вакуумный насос для герметизации упаковочной машины

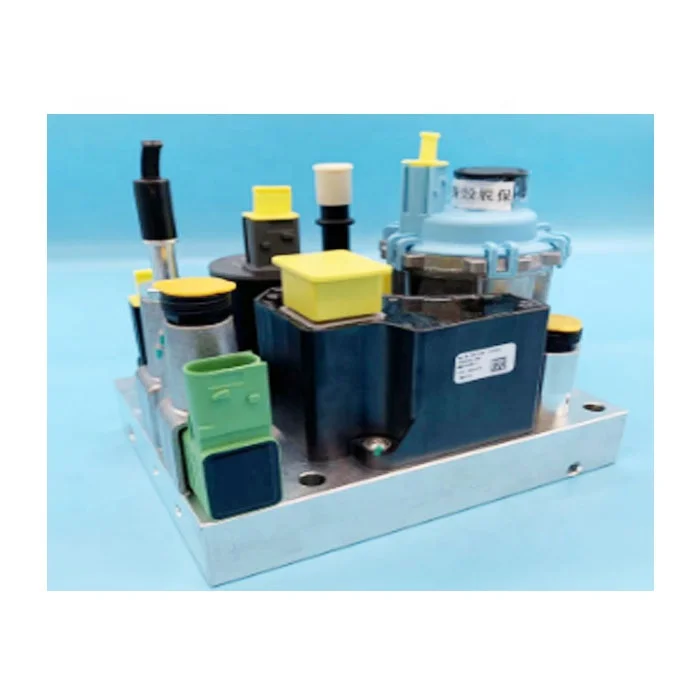

Евро VI Выхлопная система для выхлопа мочевины насос для Деф-насоса 85020666 восторженные отзывы

Насос для мочевины

Высокопроизводительный FL-83 220 В 25 фунтов/кв. Дюйм, высокообъемный 5-камерный мембранный насос, самовсасывающий насос низкого давления для розлива растворителя для мочевины

Высоковязкий насос для переноса меда, пищевой двухроторный погружной водяной насос, насос для измерения мочевины для шоколада и меда

Водостойкая кислородная фонтанная помпа

Новые поступления

Новинки товаров от производителей по оптовым ценам