3w smd 1616 Flat high power uv 395nm 400nm 405nm led

- Категория: >>>

- Поставщик: SUPER BRITE LTD.

Сохранить в закладки 60573972495:

Описание и отзывы

Характеристики

1616 3W Flat UV LED

AT1616Q15-3WEV3940

1616 LED, is one of the smallest high power LED footprint available by All Brite,

has offered extended solid-state lighting design possibilities.

The 1616 LED's combination of consistent design across all configurations and

its small size permit improved color mixing and optical control, compared to the larger 3535 LED.

The 1616 LED is designed with All Brite unique packaging technology

which providing high stability reliability.

The 1616 LED qualifies as the JEDEC Level 1 MSL sensitivity level and

suitable for SMD process, Pb free reflow soldering capability,

and full compliance with EU education of Hazardous Substances (RoHS) legislation.

Features

•Best Moisture Sensitivity: JEDEC Level 1

•RoHS compliant

•UV gluing, UV curing, UV marking

•UV drying of printing inks and lacquers•Currency inspection

•Forensic analysis -urine, protein stains

•Leak detection using fluorescent dyes

•Detects fluorescing minerals and gems

•Indoor Lighting

•Outdoor Lighting

Flux Characteristics , TJ= 25°C

Optical Characteristics at 350mA, TJ= 25°C

Electrical Characteristics, TJ= 25°C

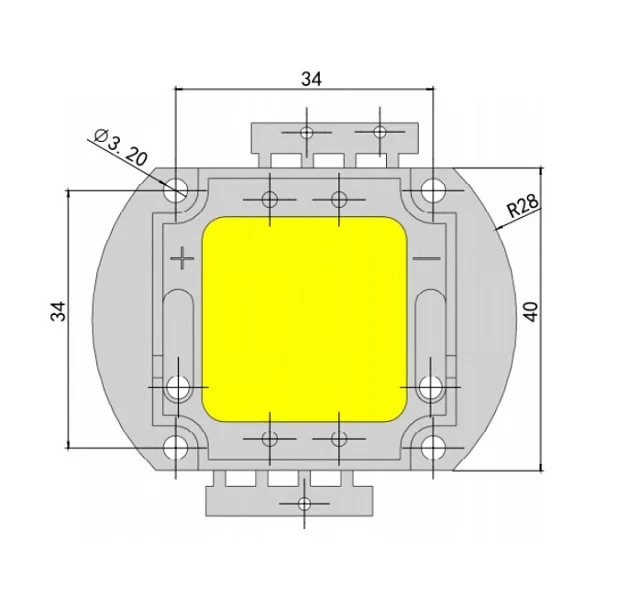

Mechanical Dimension

1.Storage

Please do not open the moisture barrier bag (MBB) more than one week. This may cause the leads of LED discoloration. We recommend storing LEDs in a dry box after opening the MBB. The recommended storage conditions are temperature 5 to 30°C and humidity less than 40% RH. It is also recommended to return the LEDs to the MBB and to reseal the MBB.

2.The slug is not electrically neutral. Therefore, we recommend to isolate the heat sink.

3.Any mechanical force or any excess vibration shall not be accepted to apply during cooling process to normal temperature after soldering.

4.Please avoid rapid cooling after soldering.

5.Components should not be mounted on warped direction of PCB.

6.Repairing should not be done after the LEDs have been soldered. When repairing is unavoidable, a heat plate should be used. It should be confirmed beforehand whether the characteristics of the LEDs will or will not be damaged by repairing.

7.This device should not be used in any type of fluid such as water, oil, organic solvent and etc. When cleaning is required, isopropyl alcohol should be used.

8.When the LEDs are illuminating, operating current should be decide after considering the package maximum temperature.

9.The appearance, specifications and flux bin of the product may be modified for improvement without notice. Please refer to the below website for the latest datasheets.

Похожие товары

Светодиодная лампа 1 Вт 3

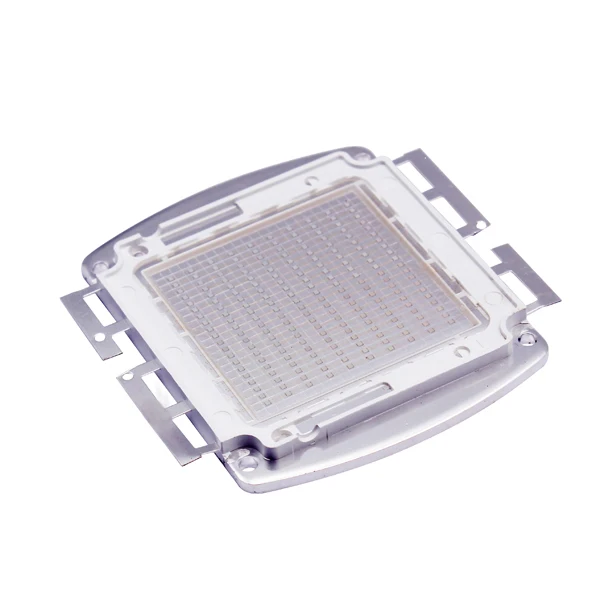

Высокая мощность излучения епистар чипы 200 Вт ИК cob led 850nm

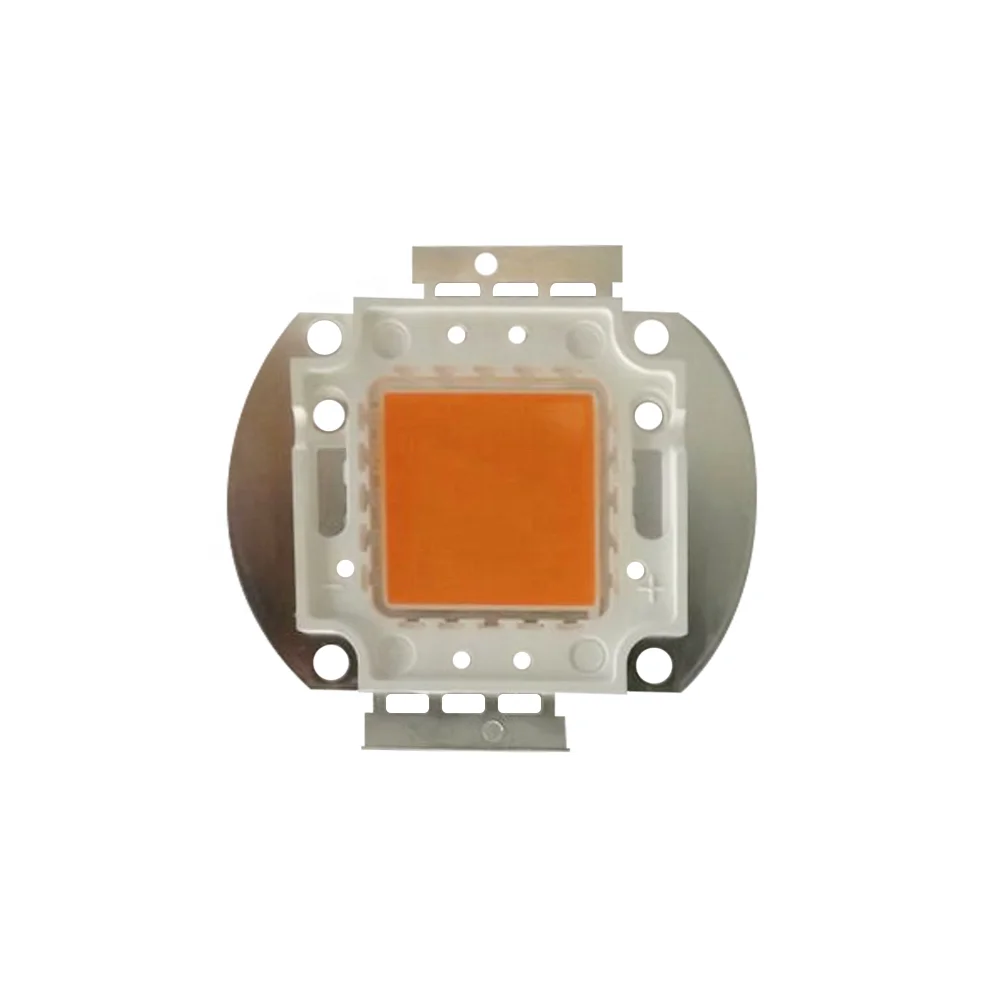

Горячая распродажа 80 Вт светодиодные бусины Cob чип Теплый Холодный белый цвет для УФ-ИК COB прожекторы аудитории чипы

Белые теплые белые бусины HPL 1 Вт 3 5 светодиодный чип высокой мощности

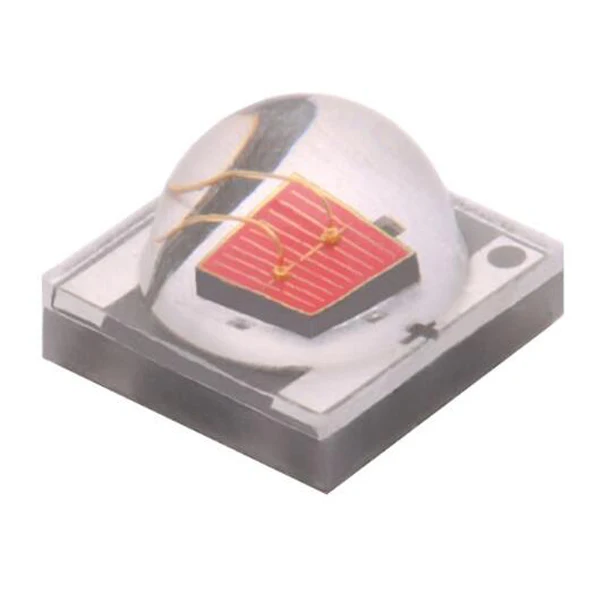

Оптовая цена 3535 SMD 1 Вт ИК 810 нм светодиод

Оптовая цена 50 Вт 100 белый COB светодиодный 4500k 6500k 8000k

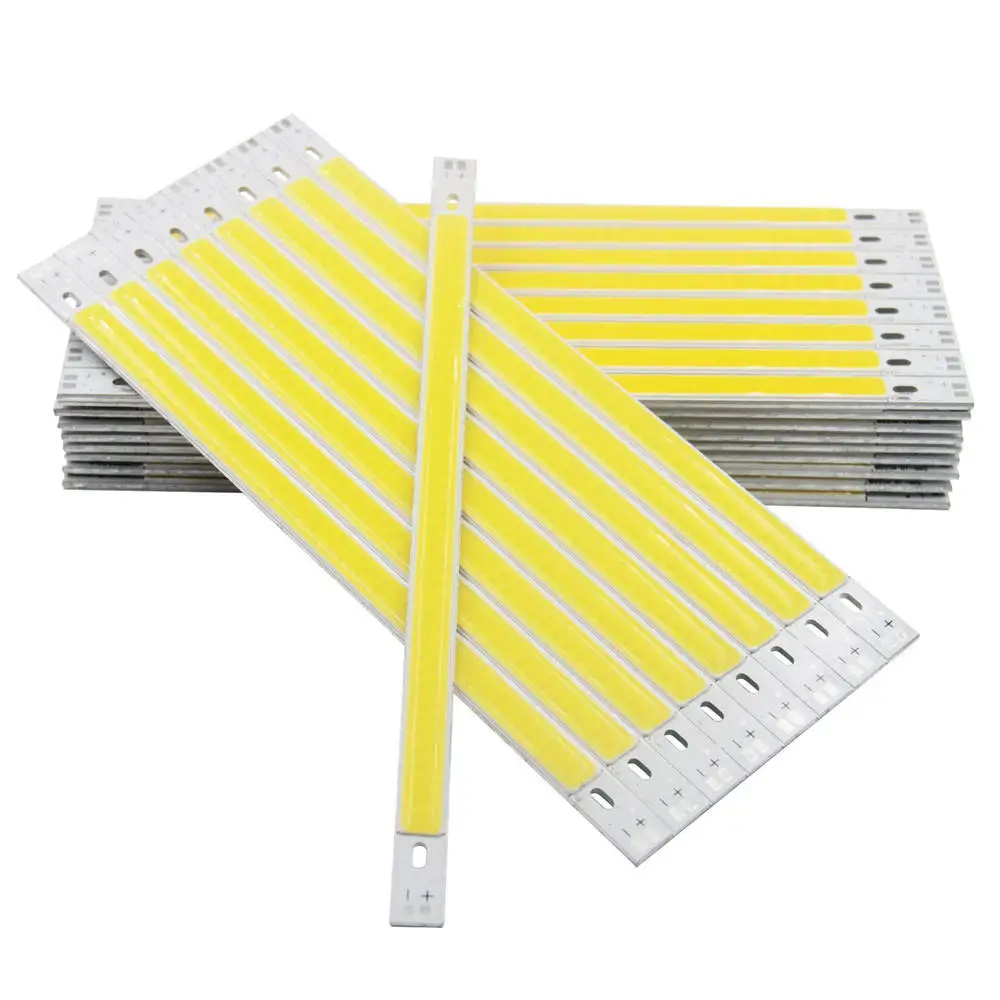

Оптовая продажа высокая яркость мощность 12 В 10 Вт Теплый Холодный белый COB Светодиодная лента для автомобильного освещения

Новые поступления

Новинки товаров от производителей по оптовым ценам