JX 350 Профессиональный полиуретановый впрыска машина для нагнетания цементного раствора предварительно окрашенная оцинкованная сталь) с низкой ценой

- Категория: >>>

- Поставщик: Shenzhen Jxc Mechanical & Equipment Co. Ltd.

Сохранить в закладки 60581078544:

Описание и отзывы

Характеристики

Techinical Parameters:

Plastic machinery | 350 |

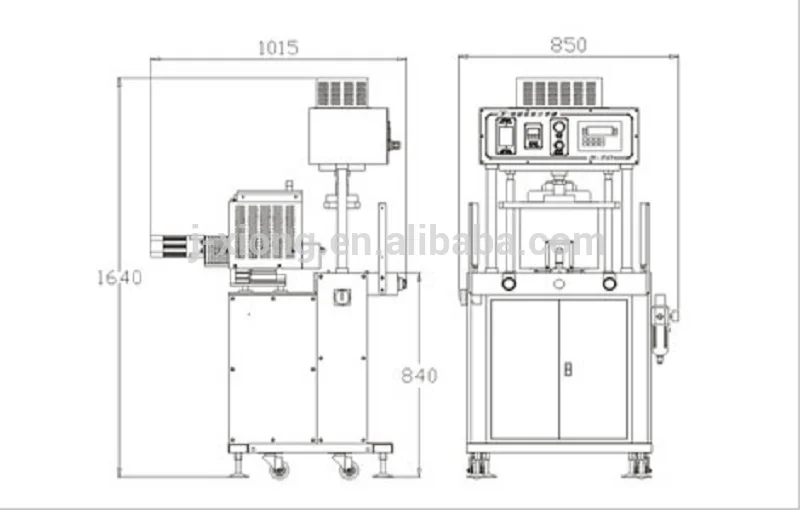

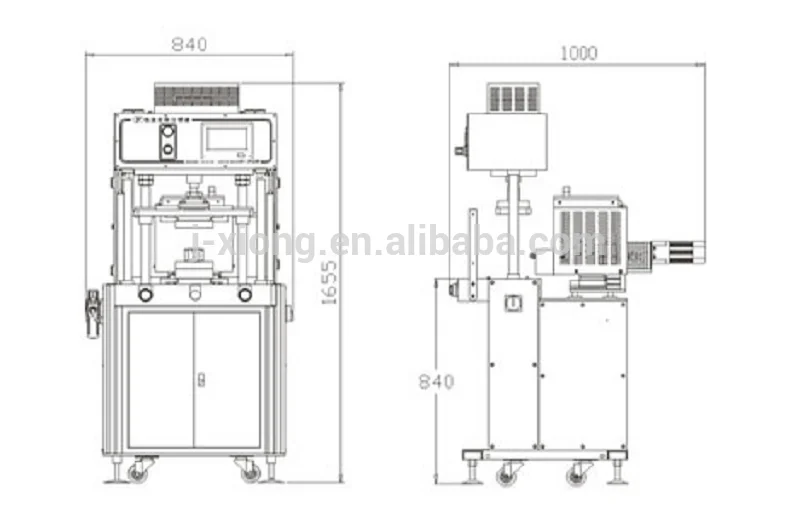

Size(mm)Machine(kg) | 850×1015×1640(270kg) |

WorkStation Height(mm) | 840 |

Plant View(mm) | 1020×850 |

Packing(mm)Size(kg) | 950×1120×1700(315kg) |

Melting Tank | (3Liter)×1 |

Gun & Tip Angle | (36.4°60°.90°)optional |

Heated Hose | N/A |

Electricity | 200-240VAC/1Phase/50 or 60Hz |

Temperature Control Zones | 2 |

Temperature Range | 70℃- 260℃ |

Max.Power(Kw) | 4 |

Working pressure(Mpa) | 0.5(Mpa)~0.8(Mpa) |

Air Consumption | 0.1m3/min |

Clamping Device | (Pneumatic) |

Clamping Force | Max.1.2Ton |

Clamping Stroke(mm) | 125mm or 150mm optional |

Control System | Text display |

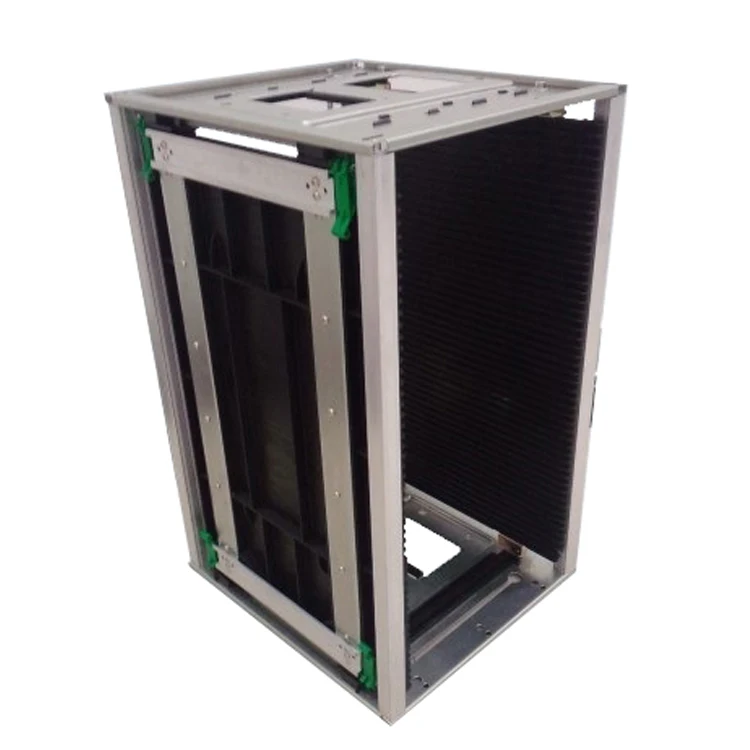

Standard Mold Set Size(mm) | 180×100×150(16kg) |

Max.Mold Set Size(mm) | 300×120×150 |

Max. Part Size(mm) | 50×45×8 |

thermoplastic low pressure injection moulding machine price

Feature

1 , Single station vertical injection system ,especially on the left and right parallel continuous wire outlet mold design is more reasonable and reliable .

2 , Console and sol system adopts the integral layout ,flexible use

3 , Console touch-screen display ,with muti-language PLC control system

4 , Glue gun is directly connected with sol cylinder by a hose ,compact structure ,stable plastic injection .

5 , Injection pressure adjustable ,DELTA temperature control module ,accurately monitor the temperature conditions .

6 , The hands switch clamping and safety grating ,emergency stop switch ,to ensure safe operation .

7 , The mold is convenient to replace ,workbench build product ejection device ,convenient to extract product .

8 , Dual cylinders is optional glue injection is more stable , high production efficency

9 , According to the human engineeing machine pedel design convenient operation .

1 , What is the product ?

It is low pressure injection machine for lithium battery , use for injection battery .

2 , how is it performance ?

It is low pressure injection systems , more efficency ,it can help you increase production run ,

and decrease production cost .

3 , what about the quality guarantee and after-sale service ?

we prrovide one year quality guarantee , full time after-sale service .

4 , we want to open a battery factory and an automating system for lithium battery , how it can do that ?

Yes , we can provide you the battery automating system and solution .

If you want to know more about it , please contact

Shenzhen JXC Mechanical & Equipment Co., Ltd.

Add.: No. 24, Hongma Road, Shangnan Community, Shajing Street, Baoan Dist.,

Shenzhen, Guangdong, China (Mainland)

Website: www(.)batteryspotwelder.com

Email: wendy.xie(@)batteryspotwelder.com

Похожие товары

Производство трехколесного велосипеда для детей из Индии по цене/дешевый трехколесный велосипед/трехколесный велосипед для детей возраста оптом

Современная Регулируемая Антистатическая стойка для магазина печатных плат из алюминиевого сплава

Оболочка и трубка и Защита от электростатического разряда, стойка для шин, стеллаж для демонстрации шин, стеллажи для хранения складов

Высокопроизводительный смеситель для корма для животных с низким уровнем шума

Дешевый флуоресцентный стерео микроскоп с отраженным светом

Автозапчасти GREAT WALL FLORID, Щетка стеклоочистителя RH, автозапчасти, автомобильные аксессуары

Biobase китайский микроскоп высокого качества, непрерывный зум, стерео микроскоп, недорогой микроскоп

Новые поступления

Новинки товаров от производителей по оптовым ценам