Лабораторный однослойный фотохимический стеклянный

- Категория: >>>

- Поставщик: Zhengzhou Keda Machinery And Instrument Equipment Co. Ltd.

Сохранить в закладки 60593020686:

Описание и отзывы

Характеристики

Laboratory Single Layer Photochemical Glass Reactor

Function introduction of stirred tank reactor

Single layer glass reactor is an equipment which is a collaboration of vacuum state, distillation, reflux, stirring, oil/water heating, heating mantle. It can do all kinds of biochemical reactions and synthesis reactions at a constant temperature condition. It is also a closed system on the whole.

Circulating water vacuum pump can pump into the reactor sorts of liquids and gases. The reflux or distillation is possible under different temperature state.

The single layer glass reactor has water/oil heating bath or heating mantle itself. Water/oil bath temperature is digital display, which can meet constant temperature state,fast temp. rising, accurate controllers.1-50L is circular and more than 50L is cylinder. After heating we can add the cooling coil in the tank to cool the material in short time.

Features of stirred tank reactor

1. GG17 high~borosilicate glass with nice physical~chemical properties; experiment temperature -100 to 400 degree C; Resistant to strong acidic properties of materials; only touching with glass parts & PTFE, no cross-contamination.

2. Precision Mechanical seal stirring to keep high vacuum degree.

3. Glass(PTFE)discharge valve, no-dead angle mixing, fast no residue discharge.

4. Frequency control speed gear motor, smooth running,high torque, automatic booster , no spark, noise free, long life.

5. SUS frame and cast aluminum material kettle body support, simple as well as strong; stable structure

6. Circulating water/oil bath, heating mantle can supply the heating origin; Cooling mode machine: cool chiller, convenient and practical

7. Scientific & innovative structure, practical, strong,

Heating principle of stirred tank reactor

The heating coil in the tank heat the transfer medium-water or oil directly,(heating mantle heat the body kettle). Then the hot water or oil pass its hot energy to material in the kettle and stirring at the same time.

Ancillary equipment of stirred tank reactor

Circulating water vacuum pump: Used to provide a vacuum source

Cool chiller: Reflux, condensation and cool the material

Technical Parameters of stirred tank reactor

Model | F-1L | F-2L | F-3L | F-5L | F-10L | F-20L | F-30L | F-50L | F-100L |

Voltage(V) | 220V/50HZ | ||||||||

Stirring Power(W) | 40 | 60 | 120 | 250 | |||||

Stirring Speed(rmp) | 0-1000 | 60~600 | |||||||

Capacity(L) | 1 | 2 | 3 | 5 | 10 | 20 | 30 | 50 | 100 |

Heating Power(KW) | 0.4 | 0.8 | 1.3 | 2 | 3 | 4 | 5 | 5 | 7.5 |

Temperature Using Range | -80℃-250℃ | ||||||||

Motor Torque |

|

|

|

| 1000g/cm | 1200g/cm | 1200g/cm | 1500g/cm | 3000g/cm |

Voltage 110V or 380V is available

Mixing power, torgue can be customized according to customers’ demands.

Refrigeration components are optional.

Company introduction:

Zhengzhou Keda Machinery and Instrument Equipment Co., Ltd. is specialized in R & D, production, sales, teaching and chemical biology pharmacy equipment integrated company. The main products are rotary evaporator, jacketed glass reactor, single layer glass reactor, circulating water vacuum pump, low temperature reaction bath (slot), low temperature cooling fluid circulating pump(cool chiller), vacuum drying oven, blast drying oven, freeze dryer, water/oil bath, magnetic heating stirrer, overhead mixer, ultrasonic cleaning machine, lift platform, etc. Besides, we act as agents of some domestic and foreign famous enterprise products, sustaining high praise in domestic junior colleges and universities, scientific research units, etc. Our products are sold to USA, Australia, Asia, Brazil,Egypt etc. countries and our customers have been fully affirmation.

Factory Size: 1,000-3,000 square meters

Year Established: 2009

Total Revenue : US$1 Million - US$2.5 Million

Registration No.: 410105000067362

Main Markets: Central America, Mid East, Oceania, Africa, South America

Please click on the picture:

1,What's the max temperature?

Usually the high borosilicate glass can withstand over 300 degree centigrade and the PTFE stirring bar can withstand about 200 degree centigrade.

2,What's the size do you have?

We can offer you 1L,2L,5L, 10L, 20L, 30L, 50L, 100L,150L.

3,How many kinds of your glass reactor?

Two types: jacketed glass reactor and single layer glass reactor.

Explosion proof is avaliable.

4,What’s the heating mode of single layer glass reactor?

Oil/water bath heating, and heating mantle.

5,Can you offer the supporting facilities?

Yes, we can offer you the vacuum, heating and cooling system as you demand.

6,What's the minimum order quantity?

One set at present.

7,What kind of payment term do you accept?

Normally we accept TT, Paypal, Western Union, Alibaba Escrow, and L/C. The exactly term with be discussed during the deal.

8, How will you delivery these goods?

It will be decided according to your quantity. Normally we will choose International Express, Air and sea.For small orders, we will send the goods by International Express like Fedex, DHL,TNT or UPS. Usually it takes 3-7work days to arrive. If big quantities we will ship by Ocean transportation, it takes one month to arrive.

If urgent, you can select shipping by Air, but freight charge will be more expensive.

9, How will package glass equipment?

We package these glass equipment in good and Non fumigation standard wooden case.

Laboratory Single Layer Photochemical Glass Reactor

Laboratory Single Layer Photochemical Glass Reactor

Laboratory Single Layer Photochemical Glass Reactor

Похожие товары

SG2 CO2 газовая защита 5 кг 15 кг MIG ER70S-6 сварочная проволока 0,8 мм 1,0 мм 1,2 мм 1,6 мм Высокое качество MIG Сварочные провода

Клейкая подставка для номерного знака самоклеящаяся Двусторонняя поролоновая

Жесткий чехол из ЭВА для ноутбука на заказ, Студенческая сумка на плечо, ударопрочный водонепроницаемый деловой чехол из ЭВА для ноутбука, ручная сумка для Chromebook

Новая глубокая V-образная центральная консоль Kinocean для продажи лодка ловли

Wholesale 915 Gram Beautiful Ruby Fuchsite loose cabochon Gemstone Ruby Fuchsite Stone Cab Jewelry Stone Cab

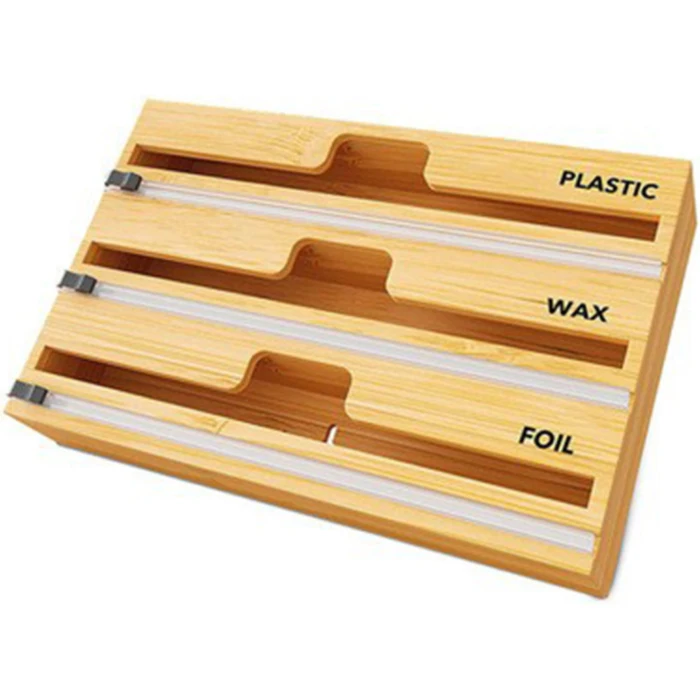

3 в 1 Совместимость бамбуковые Организатор с запахом диспенсер с резаком и логотип для кухни с выдвижными ящиками

Традиционная лапша PHO из рисового порошка из Вьетнама

Новые поступления

Новинки товаров от производителей по оптовым ценам