50ZJF резиновый выстроились бак Slurry Scum насос для целлюлозно бумажной промышленности

- Категория: >>>

- Поставщик: Shijiazhuang Naipu Pump Co. Ltd.

Сохранить в закладки 60608426506:

Описание и отзывы

Характеристики

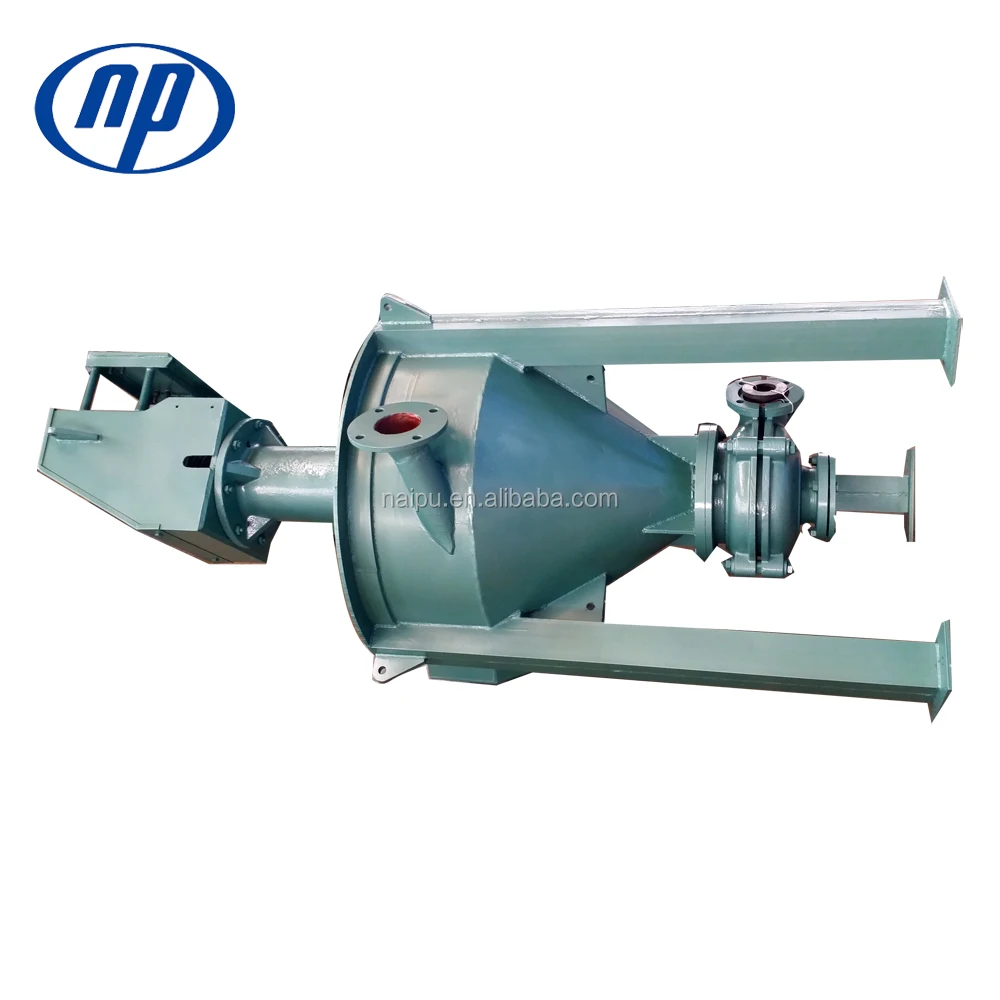

50ZJF Rubber Lined Tank Slurry Scum Pump for Pulp and Paper Industry

1. What is a froth pump?

The ZJF froth pumps has been designed to increase the pump ability of frothy slurry. The pump operation is similar to hydrocyclone seperation.

The basic principle of the froth pump operation is to de-aerate or partially de-aerate the froth before it enters the pumping. Its handling capacity of the pump is muchhigher than that of other types of slurry pump without shaft seal and sealing water.

2. What advantage of ZJF slurry pump?

The advantages of the pump are of excellent performance, easy assebly & disassembly, high reliability and etc.

| High efficiency | Handing solids-liquid mixture, special for delivering frothy pulp generated in flotation machines in metalliferous and coal flotation circuits. |

| Wide usage | Handling all applications involving of air entrained slurries, such as flotation froth in base metal concentrators, phosphate and apatite washing plants and calcium carbonate upgrading plants. |

| As a mixing and distribution unit, where dry powder has to be mixed (and wetted) with water. It can also be used with cement in ready mixed concrete sand for grouting and injection mixing. |

1. Froth pump construction drawing

2. Main part number at the drawing

| 1.Bearing 2.Bearing Assembly 3.Tank | 4.Frame Plate 5.Cover Plate |

3. Materials of construction

| LINERS | IMPELLERS | CASING | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS |

Standard | Chrome Alloy | Chrome Alloy | SG Iron | SG Iron | Chrome Alloy | Chrome Alloy | SG Iron | Rubber |

Options | Ferralium | Ferralium | SG Iron | MS | NI Resist | NI Resist | EN56C | Ceramic |

ZJF froth pump selection chart

( Note: Approximate performance for clear water,to be used for primary selection only.)

Vertical Froth Pump performance parameters

Type | Allowable Mating Max. Power(Kw) | Clear Water Performance | Impeller | |||

Capacity/ m³/hr | Head/m | Speed/rpm | Max Efficiency/% | Diameter/mm | ||

50ZJF-QV | 15 | 7.2-33 | 5-30 | 800-1800 | 45% | 229 |

75ZJF-QV | 20 | 10-104 | 10-28 | 700-1500 | 55% | 268 |

100ZJF-RV | 40 | 15-130 | 6-28 | 500-1050 | 55% | 397 |

150ZJF-SV | 75 | 55-330 | 6-25 | 350-680 | 55% | 560 |

Naipu pump produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting.

|  |

| 2 QV-AF Vertical Froth Pump | 3 QV-AF Vertical Froth Pump |

|  |

| 6 RV-AF Froth Pump | 4 RV-AF Froth Pump |

CE, SGS, ISO9001 Certification

Shijiazhuang Naipu Pump Co., Ltd is a professional manufacturing enterprise of slurry pumps and spare parts. Which own Mould Workshop, Casting Workshp, Machining Workshop and Assembly Workshop.

Katherine Hou

Похожие товары

100ZJF вертикальный центробежный шламовый насос для пены/Bomba de espuma

Центробежный насос мобильный четырехколесный тип прицепа большой поток затопления дренажный грузовик

Пропорциональный насос для подачи удобрений химической промышленности Аква-Дозирующий осевой-поршневой-переменный-насос

Высококачественный лидер продаж профессиональный высокопроточный поршневой насос с поршневым насосом дозирующий

Профессиональный поршневой насос с высоким потоком поршневого насоса дозирующего

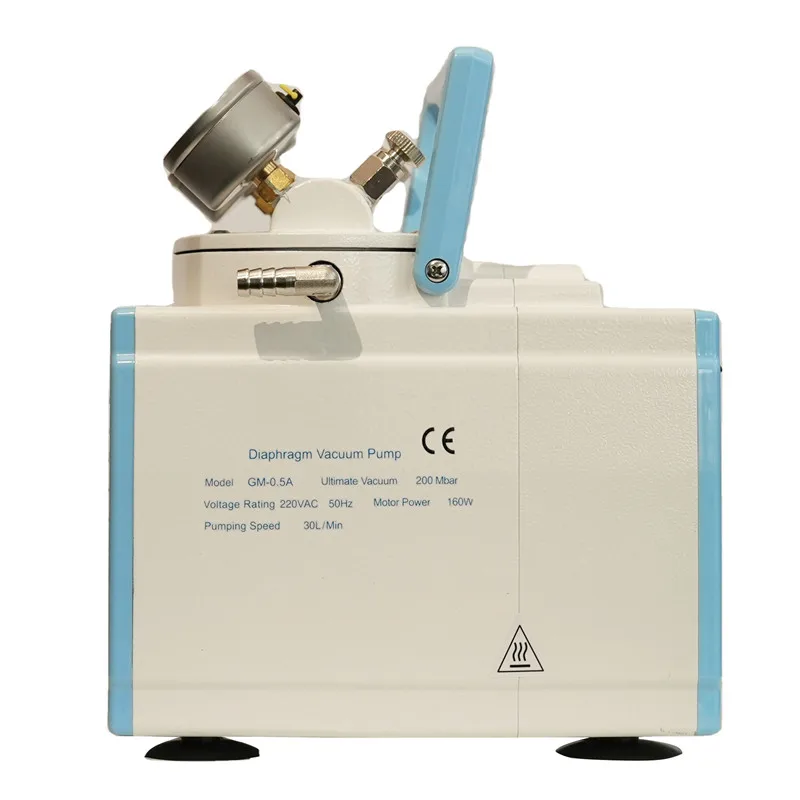

Поставщик вакуумного всасывающего насоса лабораторного аппарата с конкурентоспособной ценой

Переносной канализационный насос высокого давления для мусорных отходов 24 В/12 В постоянного тока

Новые поступления

Новинки товаров от производителей по оптовым ценам