Автоматическая машина для розлива масла бутылок с

- Категория: >>>

- Поставщик: Zhangjiagang Fillex Beverage Machinery Co. Ltd.

Сохранить в закладки 60642868912:

Описание и отзывы

Характеристики

Products Description

WEIGHTING TYPE FILLING MACHINE

Feature: Simple and straightforward liquid systems, custom engineered for every application.

Benefit: Super control over the filling process, no overhead bowl, easy access for cleaning and

maintenance.

Feature: Superior design filling valves with advanced CIP capabilities.

Benefit: Consistent and accurate fill weights, and reduced cleaning and maintenance requirement.

Feature: Unique Windows-based software with powerful reporting capabilities.

Benefit: Continuous monitoring and self-adjustment of filling process advanced packaging line

management tool.

Benefit: Super control over the filling process, no overhead bowl, easy access for cleaning and

maintenance.

Feature: Superior design filling valves with advanced CIP capabilities.

Benefit: Consistent and accurate fill weights, and reduced cleaning and maintenance requirement.

Feature: Unique Windows-based software with powerful reporting capabilities.

Benefit: Continuous monitoring and self-adjustment of filling process advanced packaging line

management tool.

Product Parameters

Why Choose Us

The Rotary Weigh Scale Filler design is based on filling every container to a pre-determined weight. This provides the most accurate fill weights regardless of fluctuations in product or container characteristics.

Monobloc Design, Combined Filling & Capping in one System.The containers are fed onto the Rotary Weigh Scale Filler. Separated, then positioned on individual load cell platforms under special custom designed filling valves. Based on bottle present’ information, the filling process begins at a filling rate designed to suit the container’s particular shape and dimensions and the product flow characteristics. Based on active weight analysis, once target weight is achieved the filling process stops and the full containers are discharged from the machine.

Monobloc Design, Combined Filling & Capping in one System.The containers are fed onto the Rotary Weigh Scale Filler. Separated, then positioned on individual load cell platforms under special custom designed filling valves. Based on bottle present’ information, the filling process begins at a filling rate designed to suit the container’s particular shape and dimensions and the product flow characteristics. Based on active weight analysis, once target weight is achieved the filling process stops and the full containers are discharged from the machine.

Related Product

Air Conveyor

- Air conveyor is fixed on the floor, with fan installed on the top. - Air filter is positioned at every entrance of air fan, to

prevent dust blown into bottles. - Bottles are held on the neck in the conveyor and transported into filling machine by blowing

power. - All are made of stainless steel SUS 304 /316. - Rack made by high quality carbon steel welded.

prevent dust blown into bottles. - Bottles are held on the neck in the conveyor and transported into filling machine by blowing

power. - All are made of stainless steel SUS 304 /316. - Rack made by high quality carbon steel welded.

RO/ UF Water Treatment For Drinking Water

Using reverse osmosis technology for desalination, reverse osmosis membrane was only 0.001 micron pore size, can be harmful to

remove dissolved solids and bacteria, viruses, etc., desalination rate of more than 99.6 percent, in line with national standards

to produce pure water, the host section contains the security filter, high-pressure pump and reverse osmosis membrane, security

filters for the fourth grade and above pre-treatment systems, high-pressure pump is the host of one of the core equipment for the

reverse osmosis membrane elements to provide sufficient pressure to overcome the penetration resistance to pressure and run to

meet the needs of a device to achieve the rated water.

remove dissolved solids and bacteria, viruses, etc., desalination rate of more than 99.6 percent, in line with national standards

to produce pure water, the host section contains the security filter, high-pressure pump and reverse osmosis membrane, security

filters for the fourth grade and above pre-treatment systems, high-pressure pump is the host of one of the core equipment for the

reverse osmosis membrane elements to provide sufficient pressure to overcome the penetration resistance to pressure and run to

meet the needs of a device to achieve the rated water.

PET Bottle Blow Molding Machine

Automatic : Full Automatic / Semi-Automatic

Bottle Capacity : 200ml-2L / 5L /10L / 3Gallon / 5 Gallon

Machine Capacity : 1000/2000/4000/6000/8000/9000

FL series fully automatic rotary stretch blow molding machine ensures first-class performance which combined with a comprehensive

bottle solution development program to devise the best solution for high speed. The machine features as high-tech component,

stable running, less power and air consumption, minimized maintenance which could meet relevant national food sanitation

requirements and shows the leading status domestically. The machine covers an extremely board range of applications including

still or carbonated water, soft drinks, edible oil, juice and sport drinks, tea and milk or milk drinks.

Bottle Capacity : 200ml-2L / 5L /10L / 3Gallon / 5 Gallon

Machine Capacity : 1000/2000/4000/6000/8000/9000

FL series fully automatic rotary stretch blow molding machine ensures first-class performance which combined with a comprehensive

bottle solution development program to devise the best solution for high speed. The machine features as high-tech component,

stable running, less power and air consumption, minimized maintenance which could meet relevant national food sanitation

requirements and shows the leading status domestically. The machine covers an extremely board range of applications including

still or carbonated water, soft drinks, edible oil, juice and sport drinks, tea and milk or milk drinks.

Shrink Labeling Machine

together with the shrink tunnel and steam generator

*Double layer holding furnace ismanufactured to take effect on energy saving

*The steam spray nozzle is divided to be adjustable three segments and the height, position and steam output of every segment can

be adjusted respectively so as to gain the perfect shrinking effect.

*The whole machine is made of 304 stainless steel with heat preservation

*The stainless steel defrosting tray collects condense water.

*The whole machine adopts the water-proof design with the convenience of operation and maintenance

*Double layer holding furnace ismanufactured to take effect on energy saving

*The steam spray nozzle is divided to be adjustable three segments and the height, position and steam output of every segment can

be adjusted respectively so as to gain the perfect shrinking effect.

*The whole machine is made of 304 stainless steel with heat preservation

*The stainless steel defrosting tray collects condense water.

*The whole machine adopts the water-proof design with the convenience of operation and maintenance

OPP Hot Glue Labeling Machine

together with the shrink tunnel and steam generator

*Double layer holding furnace ismanufactured to take effect on energy saving

*The steam spray nozzle is divided to be adjustable three segments and the height, position and steam output of every segment can

be adjusted respectively so as to gain the perfect shrinking effect.

*The whole machine is made of 304 stainless steel with heat preservation

*The stainless steel defrosting tray collects condense water.

*The whole machine adopts the water-proof design with the convenience of operation and maintenance

*Double layer holding furnace ismanufactured to take effect on energy saving

*The steam spray nozzle is divided to be adjustable three segments and the height, position and steam output of every segment can

be adjusted respectively so as to gain the perfect shrinking effect.

*The whole machine is made of 304 stainless steel with heat preservation

*The stainless steel defrosting tray collects condense water.

*The whole machine adopts the water-proof design with the convenience of operation and maintenance

Shrink Wrapping Machine

The Machine is developed for mineral water,pop-top cans,glass bottle,beer etc.combination packing with stable function,and the

packed articles tight and orderliness.This is a fully automatic production line integrated with such processed as automatic

conveying,feeding,tube management,cutting shrinking and cooling shaped-fixing flow.For large collectively counted case (box or

can)packing,it is preferred to encase with PE or PVC Shrinking film before shrink package.

packed articles tight and orderliness.This is a fully automatic production line integrated with such processed as automatic

conveying,feeding,tube management,cutting shrinking and cooling shaped-fixing flow.For large collectively counted case (box or

can)packing,it is preferred to encase with PE or PVC Shrinking film before shrink package.

Company Profile

FILLEX was established in 2006,possessed with 10000 square meters standard workshop and more than 60 professional workers.FILLEX has adhered to our long-term concept of "Packing Ideas".During the 10 years since establishment of our company, our filling machine are sold to domestic provinces and cities, also to many other countries like the United States, Canada, Ghana, Peru, Russia, South Africa, Vietnam, Philippines, Pakistan, Malaysia and so on. We provide with them solutions for blow molding, water treatment,juice processing system, filling and packaging solutions. They are mainly for liquids such as pure water filling machine, fruit drinks filling machine, carbonated beverages filling machine, beer filling machine, condiments filling machine, cosmetics filling machine and so on.FILLEX was established in 2006,possessed with 10000 square meters standard workshop and more than 60 professional workers.FILLEX has adhered to our long-term concept of "Packing Ideas".During the 10 years since establishment of our company, our products are sold to domestic provinces and cities, also to many other countries like the United States, Canada, Ghana, Peru, Russia, South Africa, Vietnam, Philippines, Pakistan, Malaysia and so on. We provide with them solutions for blow molding, water treatment,juice processing system, filling and packaging solutions filling machin. They are mainly for liquids such as pure water, fruit drinks, carbonated beverages, beer, condiments , cosmetics and so on.

Product packaging

Why Choose Us

1.we are a professional manufacturer in every kind of soft drink production machine , filling machine.

2. We have the certifications of ISO, CE and so on for our filling machine.

3. Our company filling machine are exported to many countries abroad every year.

4. We can offer free technician support and consultation to help you to order a new filling machin. and start a new company.

5. We can offer one year guarantee for the filling machin you ordered freely.

6. W can send our technician to your country for filling machin commissioning and instruction.

7. Our filling machin. are with good quality and good price.

8. Your inquiry will be replied within 24 hours, you are welcome to contact me in your convenience, please feel free to contact me if any question you have for filling machine.

2. We have the certifications of ISO, CE and so on for our filling machine.

3. Our company filling machine are exported to many countries abroad every year.

4. We can offer free technician support and consultation to help you to order a new filling machin. and start a new company.

5. We can offer one year guarantee for the filling machin you ordered freely.

6. W can send our technician to your country for filling machin commissioning and instruction.

7. Our filling machin. are with good quality and good price.

8. Your inquiry will be replied within 24 hours, you are welcome to contact me in your convenience, please feel free to contact me if any question you have for filling machine.

FAQ

Q:What are you main filling machine?

A:Fillex Machinery Co., Ltd. is a 10-year-old manufacturer specializing in the production of complete beverage filling machinery and equipment. Such like : Semi-automatic blow molding machine , automatic blow molding machine ,RO water treatment , UF water treatment ,Pure water filling machine , Juice filling machine , Pulp juice filling machine , Beer filling machine , Oil Filling Machine , Wine Filling Machine , Can filling machine , Pet bottle filling machine , Glass bottle filling machine , 5 gallon water filling production line , carbonated soft drink production line ,, three-in-one filling machine, beverage equipment, bottle unscramber machine,Opp hot glue labeling machine,shrink Label Machine , shrink wrapping machine , carton packaging machine, UHT ,sterilizer,date printer,etc.

We can help you to build a new beverage factory , can help you design the bottle , design the filling line drawing... Any questionabout this filling machine or our factory ,please contact us ,sincerely serve for you .

Q:How can I install my filling machine when the filling machine arrives?

A:We will send the engineers to help you install and test the machines , but the Visa fee, round tickets, accommodation, eating, and the allowance of 80USD per day per person will be on customer's side. Or the customer can send the engineer to our company to complete the inspection of the goods, as well as the installation and training lessons ,but the Visa fee, round tickets, accommodation, eating, and the allowance will be paid by customers .

Q:What's your guarantee or the warranty of the quality of the water filling machine?

A:We offer you high quality filling machine with 1 years guarantee . we will give u free spare parts in 1 years.

If during the warranty period, the quality or specification of the goods is found to be inconsistent with the contractual

requirements, or if the goods are found to be defective (including potential defects or the use of unqualified materials, etc.), the buyer has the right to use the inspection documents issued by the statutory authority. During the warranty period of the goods, the buyer shall make a claim against the seller.

Q:Where is your company located ?How can i visit there to check filling machine?

A:Our factory is located in zhangjiagang City,Jiangsu Province,China. You can fly to Shanghai Pudong International Airport and we are warmly welcome to visit us.(Provide pick-up service.)

Q:How can l get some samples?

A:We have no sample.we will send you more pictures and video about this filling machine,and welcome to visit our factory to see the machine running in the factory.

Q:How about the quality of your filling machine ?

A:Our company guarantees that the products provided are brand new, unused, with the latest design and suitable materials, and comply with the quality, specification and performance of the contract in all respects. And all the electric element we all use the famous brand around the world , such like Schneider ,Mitsubishi etc..

Q:What's the delivery time of your filling machine ?

A:7-45 days after the T/T deposit or L/C.(The premise is to receive customer’s samples and deposit).

A:Fillex Machinery Co., Ltd. is a 10-year-old manufacturer specializing in the production of complete beverage filling machinery and equipment. Such like : Semi-automatic blow molding machine , automatic blow molding machine ,RO water treatment , UF water treatment ,Pure water filling machine , Juice filling machine , Pulp juice filling machine , Beer filling machine , Oil Filling Machine , Wine Filling Machine , Can filling machine , Pet bottle filling machine , Glass bottle filling machine , 5 gallon water filling production line , carbonated soft drink production line ,, three-in-one filling machine, beverage equipment, bottle unscramber machine,Opp hot glue labeling machine,shrink Label Machine , shrink wrapping machine , carton packaging machine, UHT ,sterilizer,date printer,etc.

We can help you to build a new beverage factory , can help you design the bottle , design the filling line drawing... Any questionabout this filling machine or our factory ,please contact us ,sincerely serve for you .

Q:How can I install my filling machine when the filling machine arrives?

A:We will send the engineers to help you install and test the machines , but the Visa fee, round tickets, accommodation, eating, and the allowance of 80USD per day per person will be on customer's side. Or the customer can send the engineer to our company to complete the inspection of the goods, as well as the installation and training lessons ,but the Visa fee, round tickets, accommodation, eating, and the allowance will be paid by customers .

Q:What's your guarantee or the warranty of the quality of the water filling machine?

A:We offer you high quality filling machine with 1 years guarantee . we will give u free spare parts in 1 years.

If during the warranty period, the quality or specification of the goods is found to be inconsistent with the contractual

requirements, or if the goods are found to be defective (including potential defects or the use of unqualified materials, etc.), the buyer has the right to use the inspection documents issued by the statutory authority. During the warranty period of the goods, the buyer shall make a claim against the seller.

Q:Where is your company located ?How can i visit there to check filling machine?

A:Our factory is located in zhangjiagang City,Jiangsu Province,China. You can fly to Shanghai Pudong International Airport and we are warmly welcome to visit us.(Provide pick-up service.)

Q:How can l get some samples?

A:We have no sample.we will send you more pictures and video about this filling machine,and welcome to visit our factory to see the machine running in the factory.

Q:How about the quality of your filling machine ?

A:Our company guarantees that the products provided are brand new, unused, with the latest design and suitable materials, and comply with the quality, specification and performance of the contract in all respects. And all the electric element we all use the famous brand around the world , such like Schneider ,Mitsubishi etc..

Q:What's the delivery time of your filling machine ?

A:7-45 days after the T/T deposit or L/C.(The premise is to receive customer’s samples and deposit).

Q:What about Product’s material and configuration use?

A:304 stainless steel, the machine frame material is iron. According to customer requirements, 316 stainless steel is available, complete machine stainless steel, and customers demand specified configuration.

Похожие товары

Уличная портативная солнечная электростанция для кемпинга 500 600 Вт

259,99 $ - 309,99 $

Рабочая одежда, огнестойкая кислотостойкая рабочая куртка, Рабочая Униформа

Большие искусственные сосновые медиаторы красные ягоды ветки для рождественских цветочных композиций

1,42 $ - 1,49 $

Шина грузовых шин закатать двери из нержавеющей стали грузовик раздвижной двери

185,00 $ - 220,00 $

Переходник с VGA на AV насадка для

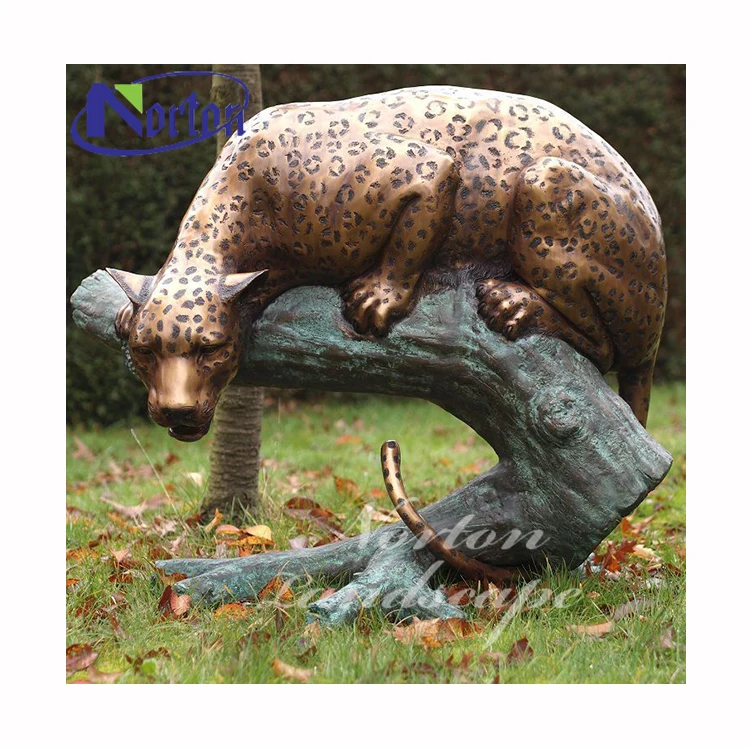

Современная медная бронзовая латунная статуя животного в натуральную величину золотого леопарда и ствола дерева скульптура для наружного украшения сада

Складной ПВХ брезент Lvju, брезент для пруда, пластиковый аквариум для рыбного хозяйства

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $