Машина для зачистки кабеля машина резки

- Категория: Cable Manufacturing Equipment >>>

- Поставщик: Changzhou Optima Technology Co. Ltd.

Сохранить в закладки 60648318405:

Описание и отзывы

Характеристики

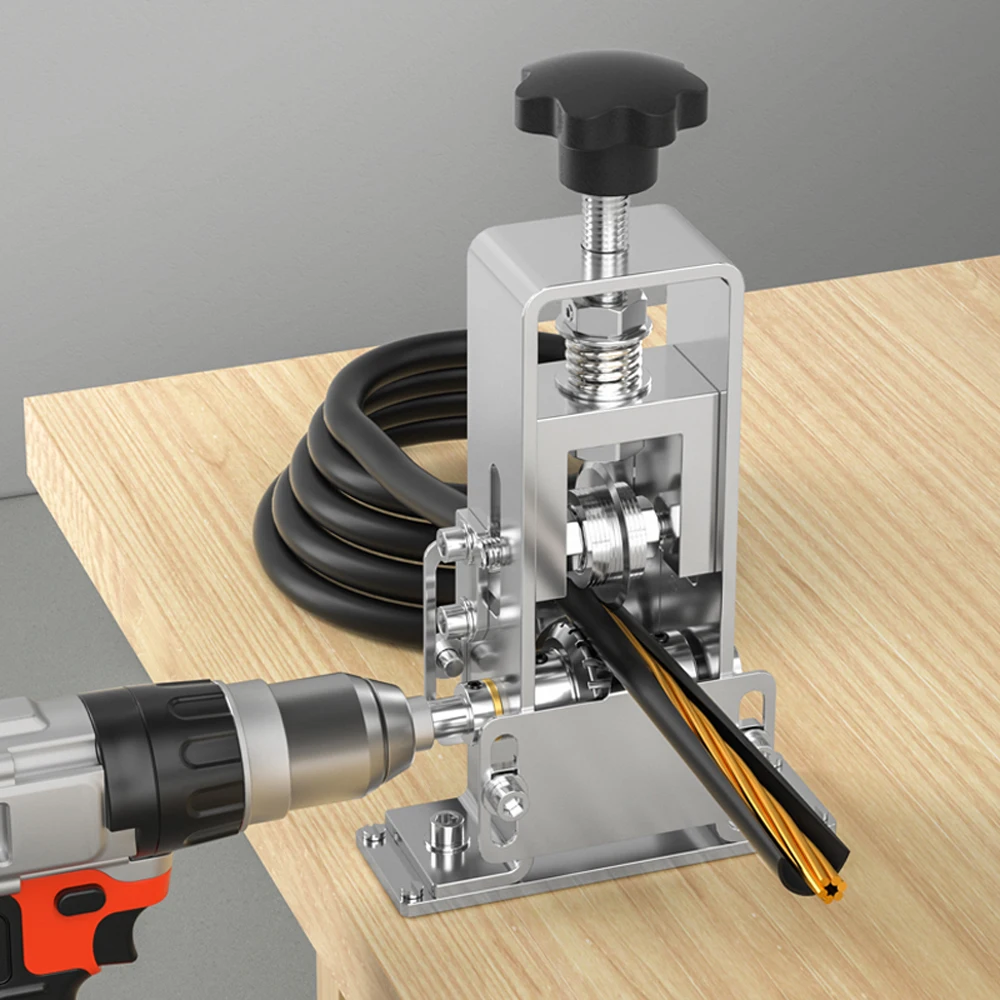

Application scope: Rubber/plastic sheathing cables of which the size is from ф10-120mm.

Function: The outer sheath and inner conductor will be stripped by blade when waste cables pass through the middle guide wheel. The blades can be adjusted freely.

Advantage: The top blade can be adjusted freely during operation. The running speed will be changed by 4 gears control.

Machine Features: Double blades can split wires from both sides, sheaths and cores are separated automatically.

Features of Optima Wire Stripping Machines include:

- Have quality guarantee and enjoy high reputation in global market.

-\tRich experience and focus on machines manufacturing for 20 years.

-\tStrictly processed control and advanced management.

-\tBest service and competitive price.

-\tHaving various hydraulic hose and hose crimping machines with different types and models.

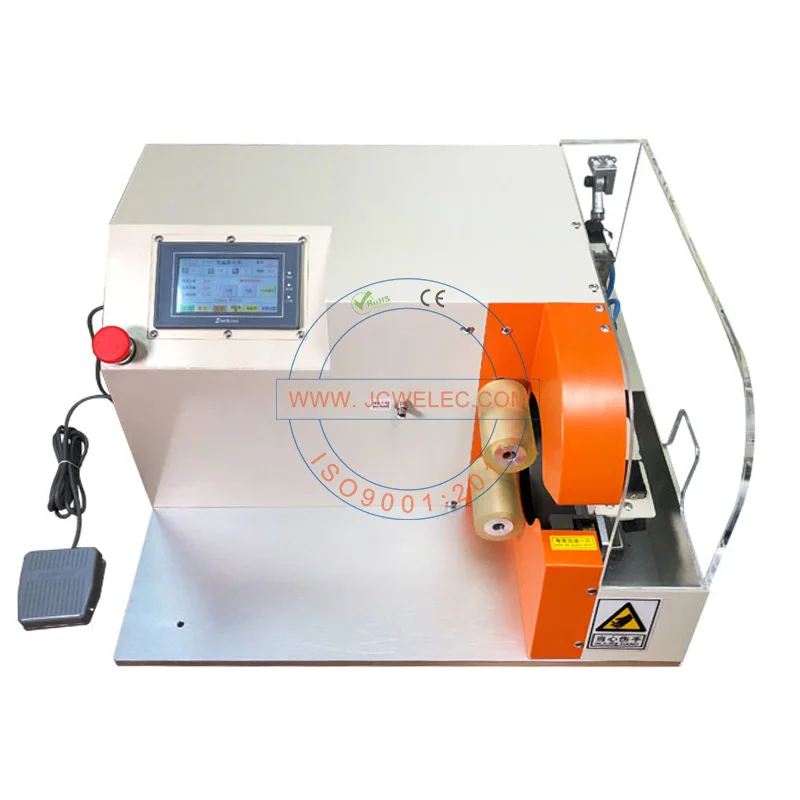

Wire Stripping Machine OBS120

OBS120 Wire Stripping with good compatibility to widely applied for wire and cable with various lengths and type of connector.

Alerting system that will warn the operator if lack of materials or breakdown of machinery.

This wire and cable automatic stripping machine developed to provide a total one-stop solution from material loading to assembly as well as unloading operation, by this way, the manufactures could increase productivity, improve product quality and enable a high level of automation to save more manpower.

Functional Description

1. Custom vibratory bowl feeder introduced to RJ connector conveyed to the workstation in constant frequency, custom design vibratory bowl (according material, size, weight and shape) ensure material conveyed automatic and alignment

2. Wire and cable employ reel and tape feeding method conveyed to the designated position

3. In accordance with the coming cable, cutting, pressing, stripping, twisting, soldering and assembly process will perform with a high accurate alignment and quick operation, the RJ connector is assembled with telephone cable, the final product is completed

4. The final product will be tested automatic and unloaded through a special unloading device

After being quoted by this specification, clauses of the following references have become the ones of this specification. For all dated references referred to, all of their subsequent amendments (excluding corrigendum content), or revisions, are not applicable for this specification. However, it is recommended that the related parties, who has come to an agreement with us based on this specification, studied whether the latest edition of these references are applicable for this specification. For undated references, their latest editions are applicable for this specification.

GB/T191-2008 (eqv ISO 780:1997, MOD) Packaging - Pictorial marking for handling of goods

GB/T 5226.1-1996 (eqv IEC 204-1:1992) Electrical equipment of industrial machines –Part 1: General requirements

SJ37-1977 Type designations for manufacturing equipment for electronic industry

ZF0500 General Specification for special equipment for electronic industry

ZF0150 General Specifications for packaging of mechanical and electrical products

Note:

GB denotes Chinese national standard.

SJ denotes Chinese Electronics Industry Standard.

ZF denotes Enterprise Standard.

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

Wire Stripping Machine model OBS120

30% T/T advance and 70% before delivering.

Equipment can be dispatched ex our factory 20 DAYS after completion of sales procedures and receipt of deposit

Warranty

The whole production line is guaranteed for one year, except blades, screen and other wearing parts. Due to equipment failure caused by violating the operation rules is not included in the warranty.

Похожие товары

Автоматическая машина для резки и зачистки тонких

HBQ-429 самый лучший продавая Провод полностью автоматическая машина для резки и зачистки кабеля Стриппер Электрический автоматический инструмент проводов

Подержанная и высококачественная кабельная машина SZADP lan для cat5e/ cat6/cat7с дешевой ценой с профессиональным

1600/1 + 3 барабанного сквистерного типа машина для укладки кабеля со стальной

Автоматическая машина для полного обертывания проводов обмотки

Новый сетевой кабель Электрический провод медный 0 6/0 8/1/1.3/1.6/2/2.6 мм обжимные клещи для зачистки инструменты щипцы плоскогубцы

1-25 мм кабель Электрический пилинг машина для зачистки проводов ручной инструмент ручная электрическая

Новые поступления

Новинки товаров от производителей по оптовым ценам