Изготовленный На Заказ корпус трубки датчика температуры 316 SS

- Категория: >>>

- Поставщик: Machining Matrix Trade (shanghai) Co. Ltd.Machining Ltd.

Сохранить в закладки 60649360561:

Описание и отзывы

Характеристики

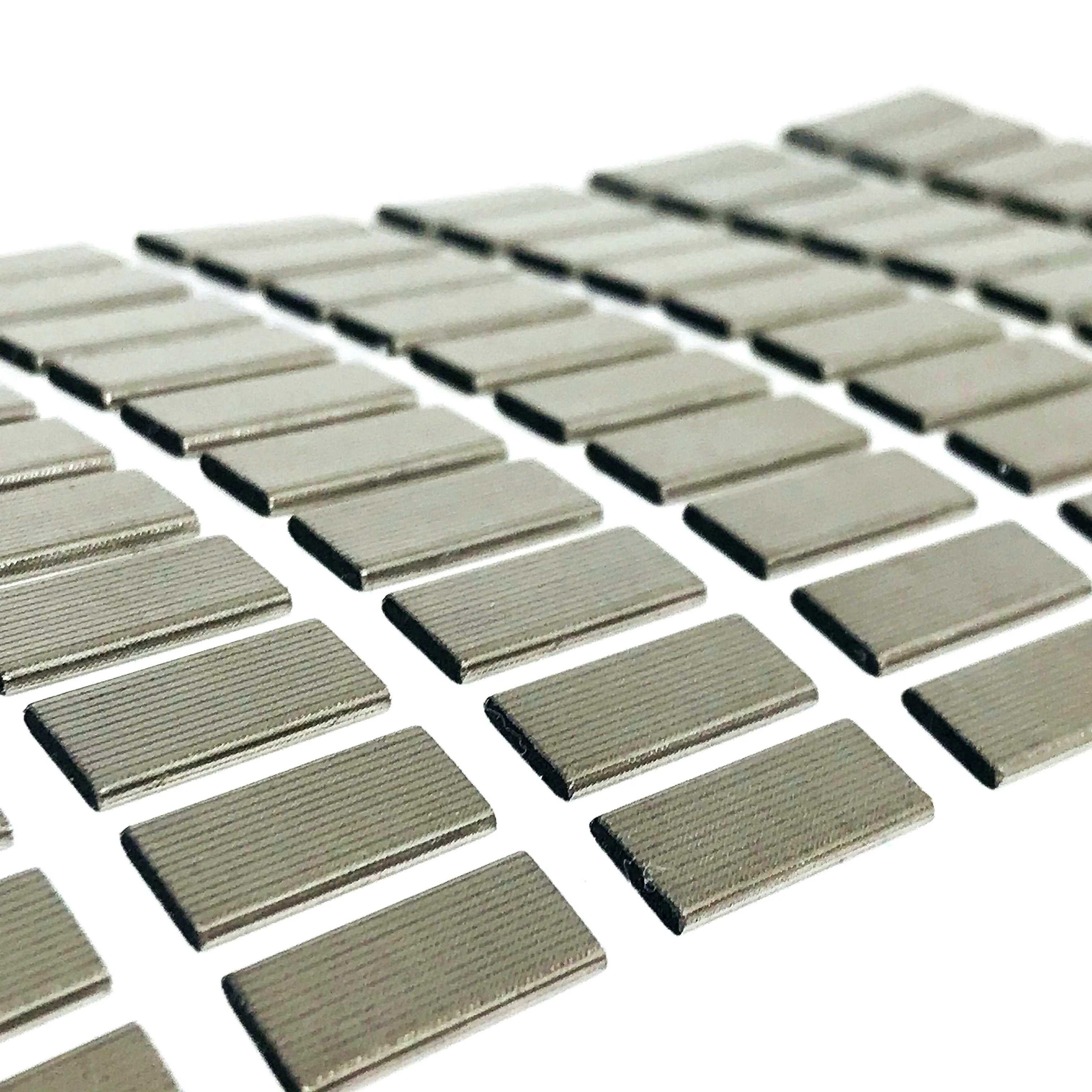

custom SS 316 temperature sensor tube housing

MMT has been supplying high precision stainless steel capillary,copper, aluminum, titanium capillary tube and other metal capillaries to abroad manufacturers who lack the time and/or experience to implement relations with quality suppliers in china since 2000. Product specifications are from OD 0.20mm specifications to 8mm, wall thickness 0.04mm to 2mm. Professional service, on time delivery and high quality components supplied at the lowest total cost make MMT team has earned high reputation from our customers.

Service | Capillary tube and capillary tube deep processing service, like cutting, swaging, slotting, bulge, barb, round close end, flat close end, bending, grooving, notching, threading, reducing and etc. |

Material | stainless steel:304,304L, 321,316,316L, 310. copper:T2,H62,H65,H68 aluminum tubes:L2Y2,LF21, 3003, 1060, 1070 and etc Titanium tube: Gr1,Gr2,Gr3,Gr4,Gr5, GR7 GR9 GR11 GR12 Special specifications can be manufactured according to customer requirements |

Process | perforate-mold-drawing-alignment-heat treatment+wire cutting or laser cutting+bending+EDM+welding+suface treatment+qc check |

Surface Treatment | Anneal/heat treat, Buff, OD/ID Polishing, Passivate, Engrave, Etch, Teflon® coat, Electropolish, Tumble, Electropolish, Grit/Bead Blast, laser engraving, Ultrasonic cleaning and etc. |

Quality Control | Spectrometer, Profile projector, Microscope, Hardness tester, universal strength tester and etc. |

Applied software | CAD,UG,PRO/E,CAM/CAE, solidwork and etc |

ROHS | Rohs compliance |

After-sale service | Guaranteed |

| Process | |

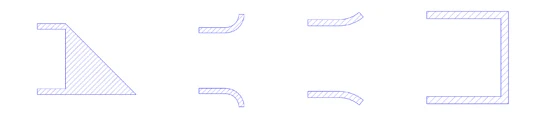

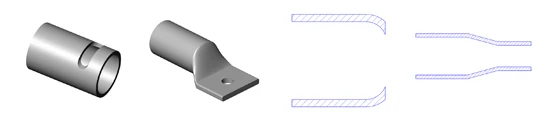

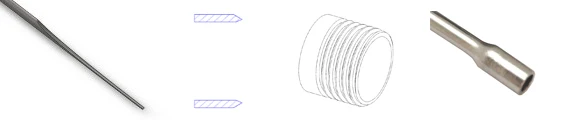

Diagrams of Common End Closures and Forming Options(many other not list)

Anti coring Axial Knurling Barb Bias Grinding

Bulge Bullet Point ID Chamfer Round Closed End

Closed End Bevel Flange Flare Flat Closure

Corset Cross Hole Groove Lancet Point

Notch/Slot Flatten Center Radiused ID Reduction Reduced

Skived Razor Edge Threaded Swaging

For more detailed informaion, please feel free to contact MMT at

Let MMT's experience work for you, and enjoy the benefits of a global supply chain for your business.

Похожие товары

Шлицевой вал высокоточный шпиндель станка трансмиссионный длинный обработка по чертежам

Высокое качество CE одобрил нейлон P66 чпу пластиковые электрические кабельные цепи сопротивления пластик буксирный трос

Подгонянные мини переключатели кнопки для продвинутой электроники

Производитель Китай электропроводящая пенная губка экранирующая прокладка Проводящая Пена

Пресс-форма KAIAO OEM ODM для медицинского оборудования

Детали Машины SMT Juki FX-3 Z6 датчик давления Asm 40159426 401-59426

Сертифицированная 9001 ISO Заводская Прямая цена изготовление листового металла на заказ Сварочная часть из нержавеющей стали и алюминия

Новые поступления

Новинки товаров от производителей по оптовым ценам