Изготовленная на заказ фабрика OEM для RC хобби модель EPP EPO самолетное пенное крыло производство

- Категория: >>>

- Поставщик: Dongguan City Duang L.M Co. Ltd.Dongguan Ltd.

Сохранить в закладки 60649430669:

Описание и отзывы

Характеристики

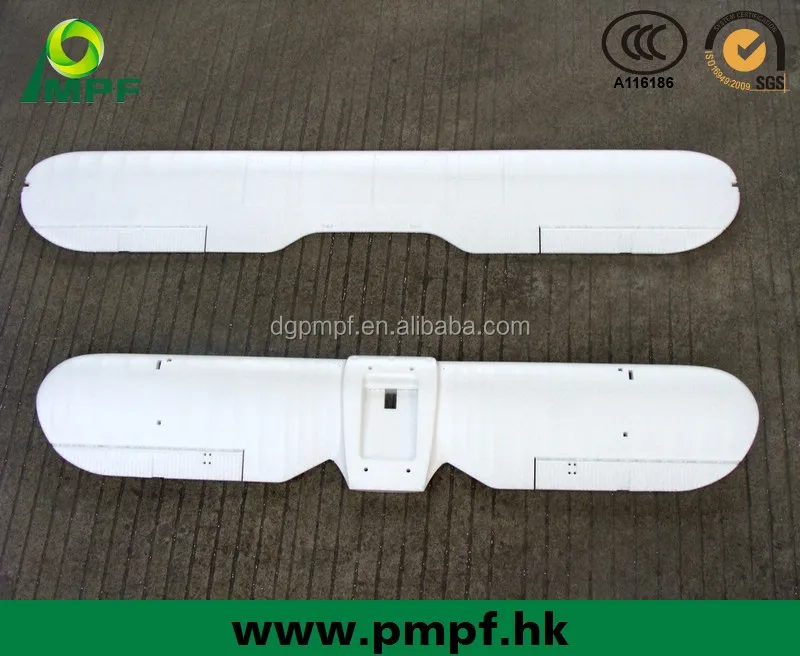

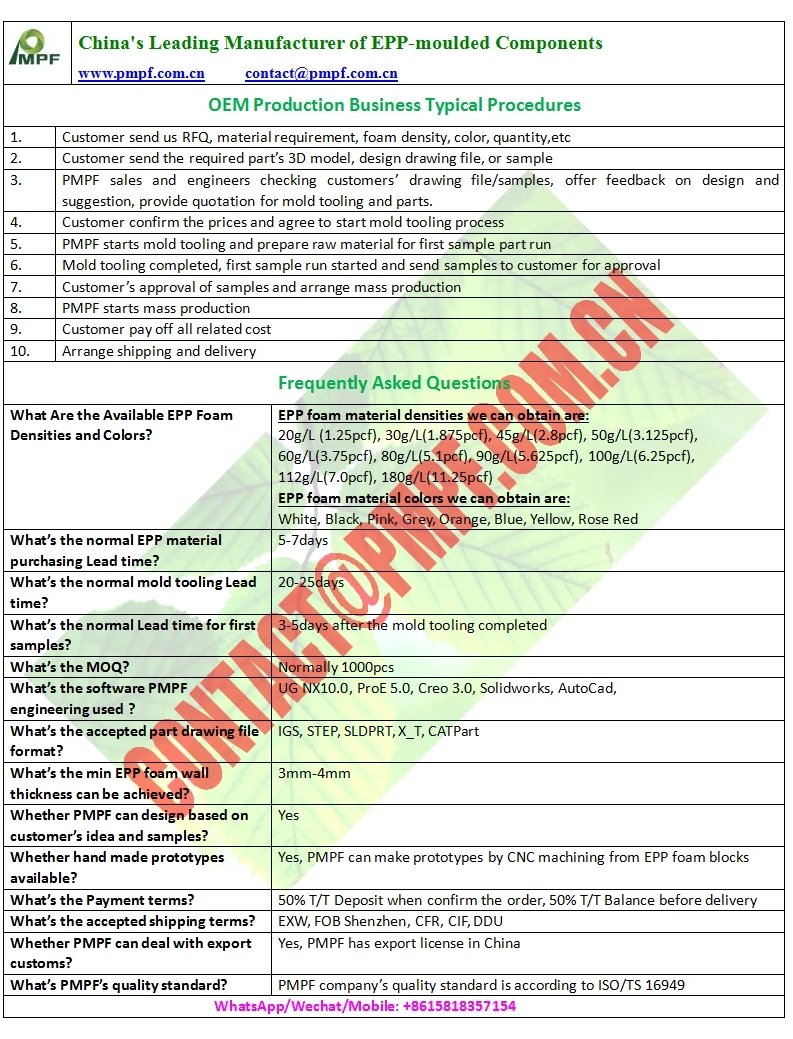

The vast majority of RC airplanes and airframes of UAV, UAS, FPV, Drones are made from one of two foam materials: EPO foam or EPP foam. Currently, many trainer planes are built from different kinds of foam. Foam is far lighter than balsa wood, so no matter how hard you crash, you take less damage. You should still expect destruction, and no RC pilot's flight kit is complete without a variety of different kinds of glues, tapes and paints, but you'll have an easier time of repairs.

Foamies, as they're known in RC circles, are generally built from one of three foam varieties: EPS, EPP and EPO.

| Description: | EPO Foam for RC airplanes and airframes of UAV, UAS, FPV, Drones |

| Material Brand: | Sekisui PIOCELAN |

| Density Available: | 50P(20g/L), 40P(25g/L), 34.5P(29g/L) |

| Application: | RC Hobby Airplane, RC Model Aircraft, RC Glider, RC Jet Plane, UAV, FPV,Drones |

| Properties: | EPO (Expanded Polyolefin),EPO is commonly used as the main construction material in electronically powered RC airplane and toy planes industry |

| Why choose EPO? | EPO products have excellent shockproof capabilities, good heating, chemical and oil enduring performance and good heat insulation. Also, the weight of EPO is light. EPO is a safe raw material. It can be recycled and is naturally biodegradable without causing white pollution. |

| Advantages of parts made of EPO foam: | -EPO is a lightweight and durable foam material. -EPO has a much better surface finish than even perfectly molded EPP and EPS, meaning a glossier and more aerodynamic surface. -EPO is compatible with a wide range of glues and paints, both of which are important to building and repairing of the airplane. -EPO does not require pre-expansion or post-curing,molding company can take less time to manufacture all of the foam sets. |

| EPP VS EPO: | EPP is more finicky about the mold and gate setup, and more susceptible to deforming after it is removed from the molds. Switching to EPO This brings us to an important announcement, which is that after consulting with the molding company, testing both EPP and EPO, and discussing amongst ourselves we have decided to use EPO as the construction material instead of EPP. We are changing to EPO for a variety of reasons. We initially selected EPP for its resilience – EPP foam doesn’t ‘crush’ when squeezed, for example – but we have learned that EPO has many advantages that we feel make it the better overall material: •As you can see in the photos, EPO has a much better surface finish than even perfectly molded EPP, meaning a glossier, more aerodynamic (and prettier!) plane . •EPO does not ‘relax’ and deform like EPP can when exposed to the elevated temperatures common in car trunks and shipping containers. •EPP is molded at a higher temperature than EPO, so the plastic skeletons are more susceptible to being deformed by the foam beads pushing past them in the molding process. •EPO is compatible with a wider range of glues and paints, both of which are important to building, repairing, and hacking the planes. •EPO is stiffer at the same density – meaning that the airframe will react faster to quick changes in direction. Another important benefit is that EPO will allow us to deliver your planes more quickly - from what we have seen, each mold tooling revision requires between one and two weeks, and getting EPP to mold correctly would likely take multiple further revisions. With EPO, we only need to do one revision to adjust the elevon hinge thickness before we can start production. Lastly, because EPO does not require any pre-expansion or post-curing, the molding company will take less time to manufacture all of the foam sets. If you have any questions or comments about EPP and EPO plane, please do not hesitate to contact us. |

EPO Foam Parts Production Photos:

| EPO foam parts mould |  |

| EPO foam moulding production |  |

| Carbon/Glass fiber inserts in EPO |  |

| EPO Foam Parts |   |

| EPO foam parts packaging |    |

Похожие товары

820 SU-27 326 мм 2 4 г 5 дюйма

FX835 ЭПП-истребитель радиоуправляемый самолет 2CH реактивный Электрический летающий игрушка

Новинка WLtoys XK A500 самолёт 2 4G 6CH 3D 6G система щеточный мотор вертолет на дистанционном управлении игрушки для детей подарок VS FX620

Быстросъемные пропеллеры защитные кольца бамперы для D JI Phantom4/PRO + V2.0

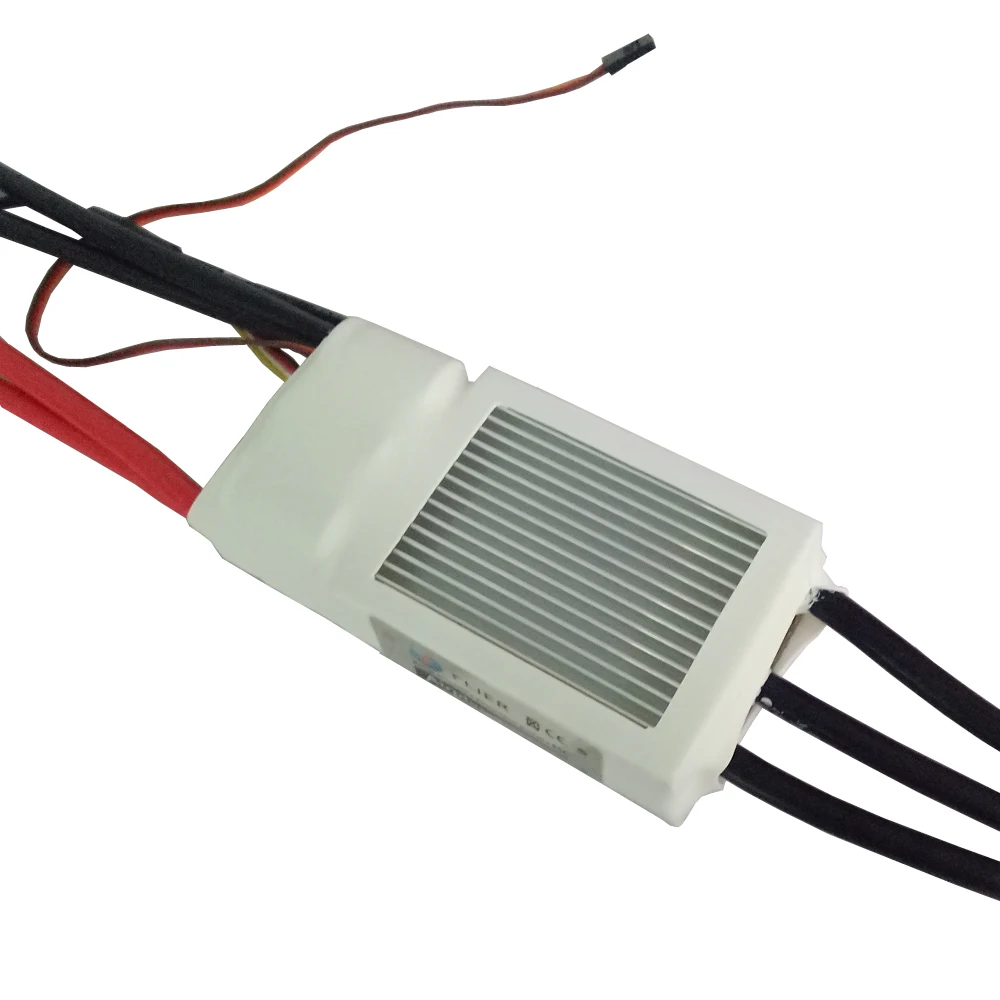

Бесщеточный двигатель мощностью 15 кВт с регулятором скорости 300/а для электропарамотора

WLtoys A180 F22 радиоуправляемый самолет 2 4 г бесщеточный двигатель 3D 6 стабильность системы 3 канала 200 м дистанционное управление расстояние

EURO REAL истребитель ERC-CF0309 EF2000 6CH 2 4 ГГц приводимого в движение с помощью электропривода Пены rc модель самолета

Новые поступления

Новинки товаров от производителей по оптовым ценам