Опорный подшипник для синхронного винт jack система подъема

- Категория: >>>

- Поставщик: Dongguan Jacton Industry Co. Ltd.

Сохранить в закладки 60665259039:

Описание и отзывы

Характеристики

Pillow block bearing is important components in synchronous screw jack lifting system. Pillow block bearing is sometimes needed to support long connecting shafts. Pillow block bearing include self-aligning replaceable bearings that are pre-lubricated. They are suitable for use under normal duty operation.

Pillow blocks, the most commonly used type of mounted units, are designed to provide shaft support where the mounting surface is parallel to the shaft axis. The bolt holes are usually slotted for adjustment during mounting. Pillow blocks are supplied in a variety of configurations. Pressed steel pillow block bearings are also available for light-duty applications.

Pillow blocks, the most commonly used type of mounted units, are designed to provide shaft support where the mounting surface is parallel to the shaft axis. The bolt holes are usually slotted for adjustment during mounting. Pillow blocks are supplied in a variety of configurations. Pressed steel pillow block bearings are also available for light-duty applications.

What is a Pillow Block Bearing?

A Pillow Block Bearing is a mounted anti-friction bearing that is contained within a solid cast iron, ductile iron or cast steel housing unit. Also referred to as a housed bearing unit, meaning they are self-contained, greased, sealed and ready for installation on the equipment. Pillow Block bearings are typically bolted to a surface, so that the attached shaft runs parallel with the surface. There are two types of housings used for pillow block bearings, solid and split housings. Solid housed bearings are single-piece housings, while split housed bearings are two-piece housings. Pillow block bearings can contain several types of bearings, including ball, roller and tapered. Shaft attachment devices can be set screw, eccentric lock, single or double set collar, concentric lock or tapered adapter. Each device has their own positive and negatives. Seals vary as well, including clearance seals, light contact, heavy contact and auxiliary type seals. Pillow Block Bearings, in most cases, also come in a fixed or expansion version. The expansion bearings allow for shaft growth and can reduce the risk of loading one bearing against the other. Choosing the best shaft mount device and seal will prolong bearing life. When installed properly, pillow block bearings can last years without needing to be replaced. Follow these steps to ensure minimal downtime and a longer service life.

*This procedure is for the most common shaft locking device set screw or set collar, utilizing a fixed and expansion unit, but the general guidelines apply to all bearing installs.

How To Install A Pillow Block Bearing?

1) Check and Clean the Shaft: First, check your shafting to ensure it is clean, round, straight, free of burrs and nicks and is not undersized or oversized, per the manufacturers specification. Use fine sandpaper or scotch bright to clean the shaft of any rust. Then use a light coat of oil to remove any debris.

2) Position the Bearings on the Shaft: When placing the bearing on the shaft, if it is necessary to tap the bearing into place, use a mallet and a hardwood block or soft steel tube against the inner ring. DO NOT strike or exert pressure on the housing or seals.

3) Lightly Bolt the Housing to the Mounting Structure: Locate the shaft in position by lightly bolting the housing to the mounting structure. Bridge over the housing mounting bolt slots with heavy washers, or heavy spring lock washers. This may help prevent loosening.

4) Establish the Final Mounting Position: Prior to securing the bolts, establish your final mounting position by aligning the bearing units by hand or a rubber mallet.

5) Securely Bolt the Housing to the Mounting Structure: Once the bearing is properly aligned, securely bolt both units to the mounting structure.

6) Ensure the Shaft can Move Axially: Ensure that the shaft can move axially through the bearing bores to confirm proper alignment. If this cannot be done, loosen the housings and realign the shaft.

7) Tighten Both Collar Set Screws: Tighten both collar set screws, and then rotate the shaft and alternately tighten to the manufacturer recommended torque values. If a torque wrench is not available, tighten the set screws until a permanent twist is established with an allen wrench.

8) Expansion Unit: If you are using an expansion unit, always lock the fixed bearing first. Move the expansion bearing axially to center in the housing. Once centered, alternately tighten the set screws on the expansion unit as you did on the fixed unit.

| Application in screw jack lifting systems |

Shipping:

1. Ocean freight: seaport to seaport, price terms CIF, FOB, EXW, CFR etc.

2. Air freight: airport to airport, price terms EXW, CRF etc.

3. Air courier: DHL, FEDEX, UPS, TNT door to door shipment, price terms DDU, CPT etc.

Packing:

100% standard exporting plywood cases.

Note: International Exporting Standard Wooden Material with Free Fumigation.

* One of the biggest orders with 1750 units screw jacks.

* Standard products with 2D Drawings(DXF, DWG, PDF) and 3D CAD Model(STEP).

* 100% quality assured with double quality inspections. Original Inspection Reports, Operation Manual, and Book Catalogue are put into the packages.

* 100% safety transportation with strong standard export plywood cases materials (free fumigation).

* International standard materials for all standard products.

* Custom design available, OEM service available, Free engineering advice and Customer label available.

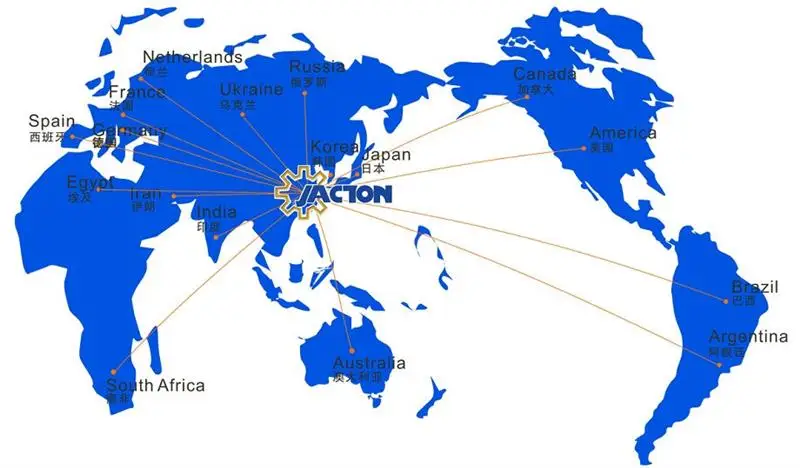

1. Theatrical solutions stage and orchestra platform lifts projects. Customers are from France, Australia, Netherlands, United Kingdom, Spain and Canada.

2. Hydroelectric power station projects and water conservancy projects. Customers are from Vietnam, Australia, Malaysia, Belgium, United States and United Kingdom.

3. Aircraft maintenance platforms and docking systems projects. Customers are from Singapore.

4. Solar panel tracking system projects. Customers are from Spain, India and Canada.

5. Bolted steel storage tanks and silos lifting solutions. Customers are from South Africa, United States, Mexico and Vietnam.

6. Dish antenna elevation and azimuth positioning projects. Customers are from Singapore, Malaysia and United States.

7. Railway wagon projects. Customers are from South Africa.

8. Beverage can production lines. Customers are from Netherlands, United States, Thailand and Indonesia.

9. Steel factories production lines. Customers are from United States.

10. Continuous PU sandwich panel production lines. Customers are from Thailand and United Kingdom.

* Manual Screw Jacks.

* Electric Screw Jacks.

* Worm Gear Screw Jacks Series.

* Bevel Gear Screw Jack Series.

* Electric Cylinders Series.

* Spiral Bevel Gearboxes Series.

* Lifting Systems and Accessories.

* Electric Linear Actuators Series.

* Geared Motor and Gear Reducers Series.

1. American Countries: United States, Mexico, Canada, Chile.

2. European Countries: Germany, France, United Kingdom, Italy, Spain, Poland, Romania, Netherlands, Belgium, Greece, Czech Republic, Portugal, Sweden, Hungary, Austria, Switzerland, Bulgaria, Denmark, Finland, Slovakia, Norway, Ireland, Georgia, Slovenia.

3. Asian Countries: Malaysia, Indonesia, Singapore, Philippines, Vietnam, Thailand, India, Israel.

4. Oceanian Countries: Australia, New Zealand.

5. African Countries: South Africa, Egypt.

JACTON INDUSTRY Co., Ltd (VAT No.: 9144190007026567X3) is one of the leading companies in the field of Screw Jacks(Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Linear Actuators, Gearmotors and Speed Reducers. We are an audited professional manufacturer and supplier by SGS (Serial NO.: QIP-ASI192186) and BV (Serial NO.: MIC-ASR202862) organizations. We have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, and consistently provide the customers with the best engineered solution for precision linear actuation, power transmission and mechanical jacking systems. Jacton Industry guarantees quality, reliability, performance and value for today′s demanding industrial applications.

FAQ

1. What type of payment methods do you accept?

We accept Wire transfer, Credit Card, Paypal, Alibaba Trade Assurance order, Western Union and L/C etc.

2. Can I get one sample to test?

Yes, sample can be at a normal price and welcomed. The transport fees are at your account.

3. How about the quality of your product?

Jacton industry is only focus on the field of Screw Jacks(Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Linear Actuators, Gearmotors and Speed Reducers.

4. OEM/ODM Accepted?

Yes, Please send you new product drawings or sample to us if you have, and we can custom-made as your required. We will also provide professional advices of the products to make the design to be maximize the performance.

5. If you can not find the product on our website,how do you do?

Please send us inquiry with product pictures and drawings by email or other ways you prefer, we'll check if we could produce.

6. Can I trust you?

Absolutely yes. Samples could be provided to test firstly, and we can use Alibaba trade assurance service to do business to guarantee both the seller and buyer's benefit, and we are golden supplier for years.

7. What's our products warranty?

One year quality guarantee for the products from your purchase date, except the human damage.

Похожие товары

1000L дистилляционное оборудование спиртовой дистиллятор установка для дистилляции

Высококачественная женская зимняя одежда 2021, укороченная куртка большого размера из искусственного лисьего меха для женщин, Пузырьковые куртки

Новое высококачественное оцинкованное металлическое ведро для шампанского вина пива льда с индивидуальным логотипом

Китайские Смарт-часы Reloj с GPS, IP68, сенсорный экран, отслеживание местоположения, фитнес-трекер Q3, смарт-браслет, GPS-часы, здоровье

Вместительные металлические двухъярусные кровати для взрослых/стальные армейские двухъярусные кровати/Военная двухъярусная кровать

Задний диффузор V-style из углеродного волокна, новый стиль для Audi R8 2017 +

Простая винтажная комнатная декоративная настенная лампа с железной водопроводной трубой

Новые поступления

Новинки товаров от производителей по оптовым ценам