Высокоскоростной вращающийся пневматического Чака шпинделя инструмент токарный станок с компьютерным числовым программным управлением JA5 25

- Категория: >>>

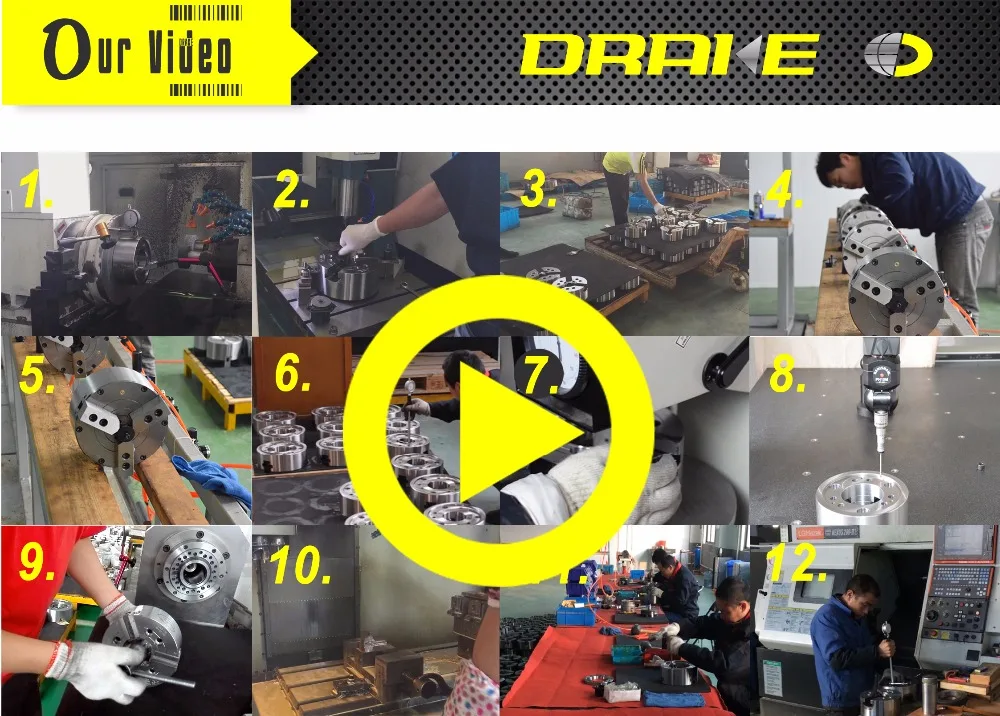

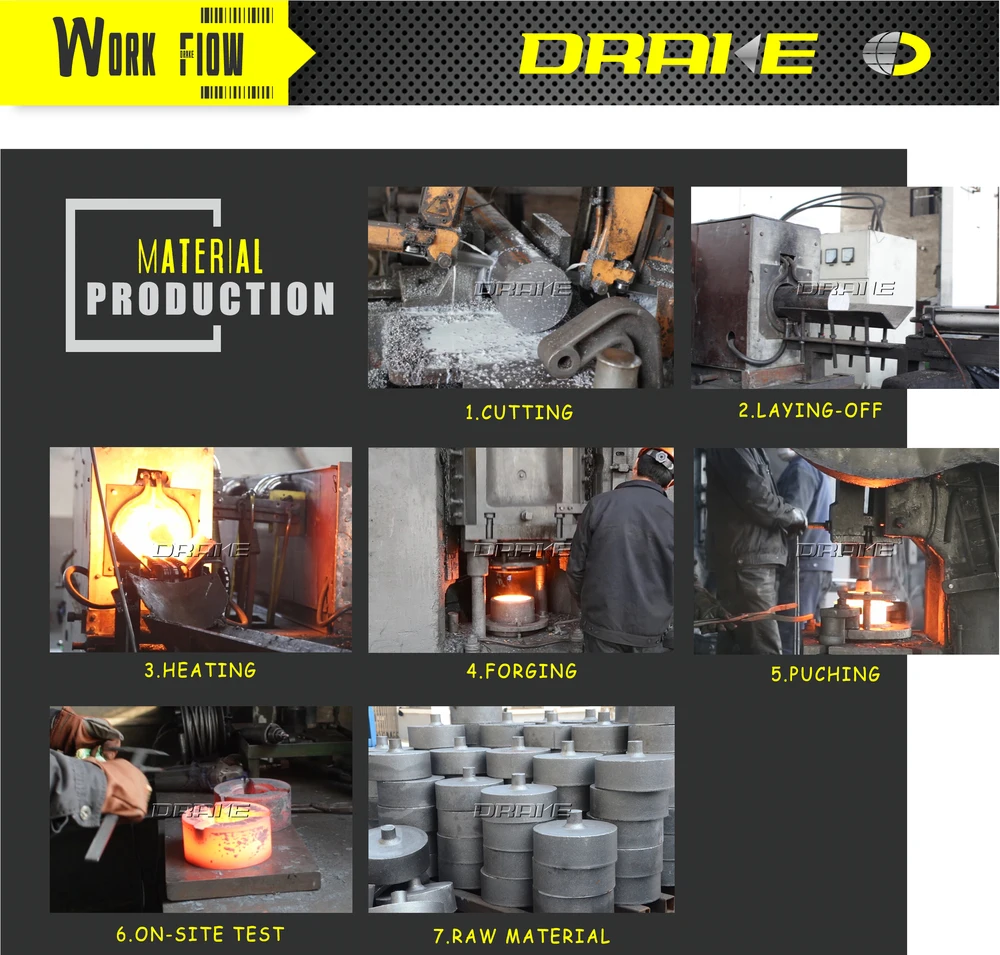

- Поставщик: Changzhou Drake International Trade Co. Ltd.Changzhou Ltd.

Сохранить в закладки 60670276766:

Описание и отзывы

Характеристики

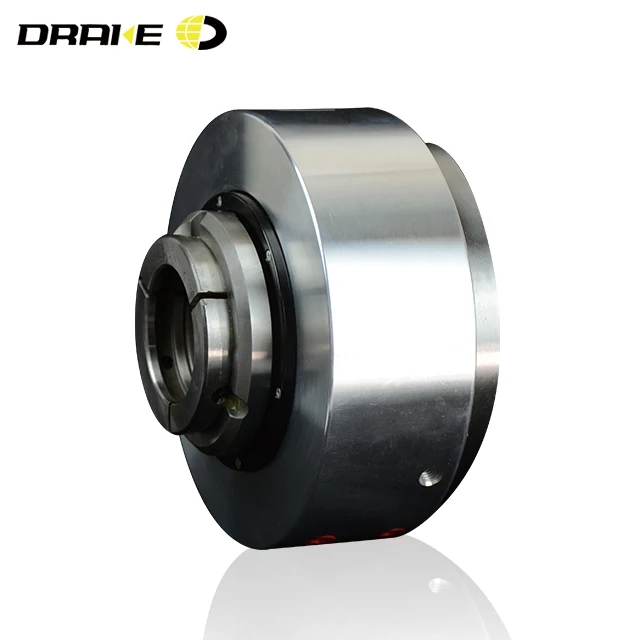

High speed rotary pneumatic chuck spindle instrument cnc lathe machine JA5-25

Technical features:

6. Widely applied to convert manual lathe into powered ones.

7. Widely applied to build special purpose machines.

8. Do not spray cutting fluid to the chuck directly.

There are three questions to answer to aid the correct choice of power chuck:

1. Type and model of CNC lathe.

2. Length of workpiece?

3. Outer diameter of workpiece?

4. Processing requirement?

Size Parameters

| Model/Spec | A | B | C | D | E | F | G | H | I | J |

| JA5-25" | 135 | 100 | 26 | 4 | 105 | 45 | 68 | 170 | 115 | M8×1.25 |

| JA7-40" | 192 | 155 | 46 | 5 | 125 | 65 | 95 | 212 | 172 | M10×1.5 |

| JA7-70" | 192 | 155 | 69 | 5 | 140 | 105 | 136 | 266 | 172 | M10×1.5 |

It is recommended to grease chucks at least twice a day in order to maximize longevity

Performance Parameters

| Model/Spec | Working pressure (kg/cm²) | Limit speed (rpm) | Clamping torque (mm) | Clamping stroke (mm) | Through-hole aperture | Max. chuck diameter | Net weight (kg) |

| JA5-25" | 2~8 | 1800 | 3 | 1.5 | Ø26 | Ø32 | 9.2 |

| JA7-40" | 2~8 | 1800 | 4 | 1.5 | Ø45 | Ø50 | 16.9 |

| JA7-70" | 3~8 | 1600 | 6 | 1.5 | Ø68 | Ø90 | 27 |

The matching products including:

1. Connecting bolt

2. Jaw pad

3. Collet

High speed rotary pneumatic chuck spindled rotary pneumatic chuck spindle

Похожие товары

Прямые продажи с завода самоблокирующийся резьбовой зажим для сверлильного станка

Высокое качество ЧПУ фрезерный 13 мм 16 BT40 BT50 интегрированный БЕСКЛЮЧЕВОЙ сверлильный патрон

APU13 APU16 1-16 мм B18 сверлильный патрон для сверлильного станка с ЧПУ

Пневматический патрон для токарного станка

Китайский производитель Yantai yum полый патрон K11 80 мм токарный станок 3 челюсти Самоцентрирующиеся котировальная цена

Быстрая ручная быстросохнущая пластина совместимая с Lang для 4/5 оси

Постоянный магнитный патрон для резки проволоки на заказ

Новые поступления

Новинки товаров от производителей по оптовым ценам