Автоматическая машина для подачи листов под давлением автомобилей хлопок копировально фрезерный станок обработки замочных ключей

- Категория: >>>

- Поставщик: Jiangsu Atong Machinery Manufacturing Co. Ltd.

Сохранить в закладки 60672732019:

Описание и отзывы

Характеристики

The working principle of the hydraulic cutting machine is down press to the mold,to cut material by dies / molds.

We can make the machine according to your specifically order, for example the color, the motor information ,the working table, the traveling head size etc.

car sound absorbent cotton -welding and cutting machine

1. Technical Parameters

model | JSAT1-800 | JSAT1-1000 | JSAT1-1500 |

Max cutting machine | 80T | 100T | 150T |

Distance between pressing board and working platform | 50-240mm | 50-230mm | 50-230mm |

Effective area of working platform | 1600*800mm | 1600*800mm | 1600*900mm |

Power of main motor | 7.5kw | 7.5kw | 11kw |

Feeding mechanism | 1.1kw | 1.1kw | 1.1kw |

weight | 6800kg | 8800kg | 12500kg |

2. Features and Advantages

car sound absorbent cotton welding and cutting machine

Features:automatic cutting and welding

PLC contr ol accurately

professional customized machinery

The machine is a large sized automatic continuous cutting machine which is applicable for cutting roll materials such as car floor mats, seats ,ceilings and steering wheels in automobile interior decoration industry ,backing plate leather ,floor tiles and carpets in decorative material industry, sand paper polished wafer and polished wheel in abrasive industry ,as well as football and volleyball in ball manufacturing industry.

1. Large-tonnage precision four-column double-cylinder double-link automatic balancing mechanism to ensure the cutting speed and accuracy of the machine, all sliding joints using central automatic lubrication device, so that wear and tear to a minimum.

2. The conveying part adopts PLC control. The servo motor drives the material to be inputted from one side of the machine. After cutting, the output from the other side ensures the feeding precision and smooth running. The feeding length can be adjusted by the touch screen. Display information to facilitate machine maintenance.

3. Servo motor clamping feed, receiving device, so that the control accuracy of ± 0.2mm.

4. Cutting under pressure when the first 10mm in contact with the knife before the automatic slow speed, so that when cutting multi-layer material, the top and bottom of the size of the error is not.

5. Due to the accuracy of the cutting balance, it can greatly reduce the loss of the cutter die and the cutting board, the edge effect is better, and the consumption of the cutting board is reduced.

6. Unique mold set structure, with the cutter and cutting height, so that stroke adjustment is simple and accurate.

7. Die fixed clamping device, easy to replace the cutter mold.

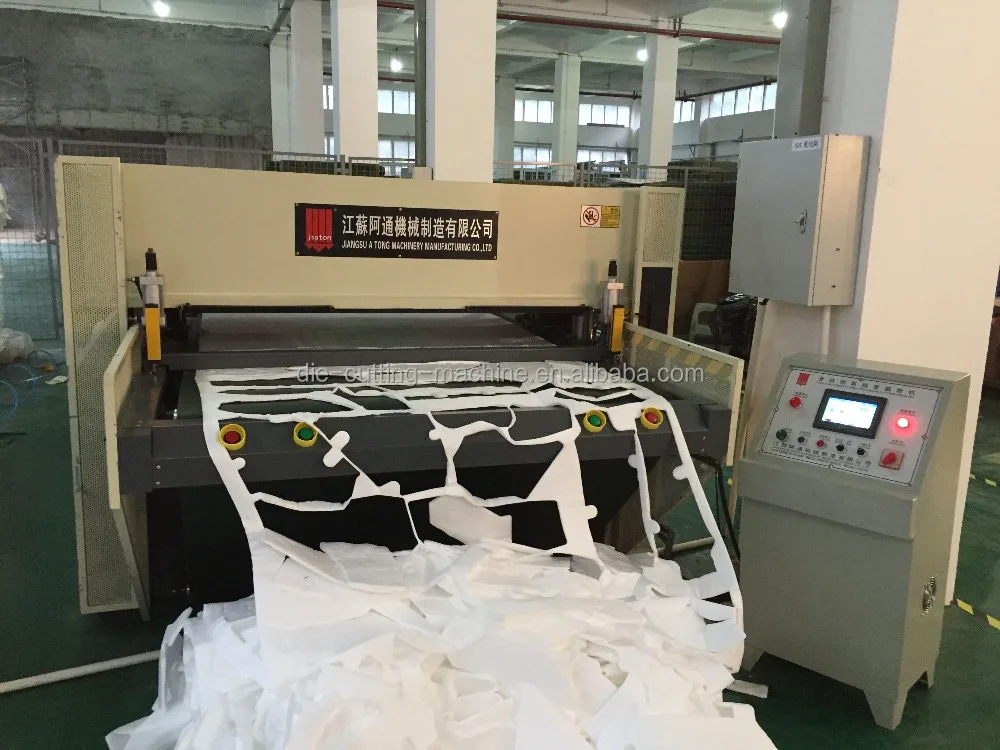

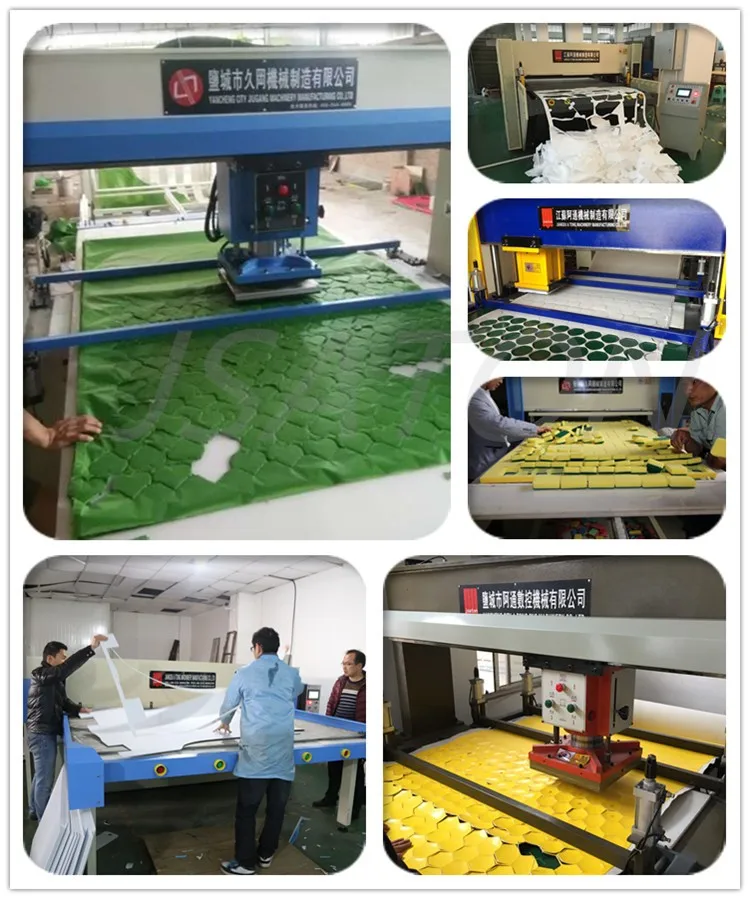

3.Our machine working show![aton.jpg]()

![.jpg]()

![.jpg]() 4. The cutting-dies

4. The cutting-dies

5.What Applications of our cutting machine?

Application Materials:

The Cutting Machine is widely used in industrial leather,plastic,rubber,sponge,foam,EVA,PVC,cardboard,paper products,fabric,home textiles,packaging materials,non woven,carpet,car cushion,felt,synthetic materials,and other non-metallic materials in various industries;Extremely suitable for cutting multiple layers of material at one time,etc.

1.We are a factory, and the price is favorable.

2. We have strict QC system.

3. We offer a free after-sales service for 12 months. all parts are for free,except the consumables and artificially damaged.

4.We can supply operation video for installation

5. Our engineers are available to service machinery overseas.

6. Our machines have been sold to over 30 countries.

Trade term:FOB,CIF,EXW

Payment Condition:30% deposit in advance. 70% balance before delivery.

Delivery time:5-15 working days after deposit.

Packing:Wooden case with plate.

Shipment:By Sea.

If you are not sure if your material can be cut by this cutting machine,we want to know the product information:

Material:

Material size: in sheets or rolls

Max. material width:

Max. material thickness:

Max.cutting length:

Send your Inquiry Details in the Below, Click "Send" !

we will reply to you at any time.

Похожие товары

Кузов для Mercedes Benz CLA Class C117 2013-2019 CLA200 CLA220 CLA45 AMG, линейный Бампер, флаг, наклейки, аксессуары

6 шт., уголки для переднего бампера из углеродного волокна Dongsai для Mercedes CLA W117 2014-2016

CLY диффузор с выхлопной трубой для 2019 + Mercedes Benz W118 CLA Upgrade CLA45 AMG задняя губа с наконечниками

Автоматическая машина для производства нетканого покрытия обуви от производителя, одноразовая машина для покрытия обуви, машина для покрытия пластиковой обуви из ПЭ

Kunlin 9 дюймов сенсорный экран Android радио жгут проводов для Kia Rio 2012-2015 с пластиковая защитная рамка с can-bus

Автомобильный мультимедийный плеер, проигрыватель на Android 11, с восьмиядерным процессором Snapdragon 8, ОЗУ 4 Гб, ПЗУ 64 ГБ, GPS, для Benz A class W176 CLA C117/X156, 12,5 дюйма

HB-801C промышленный micoкомпьютер, автоматическая машина для склеивания обуви и кожи

Новые поступления

Новинки товаров от производителей по оптовым ценам