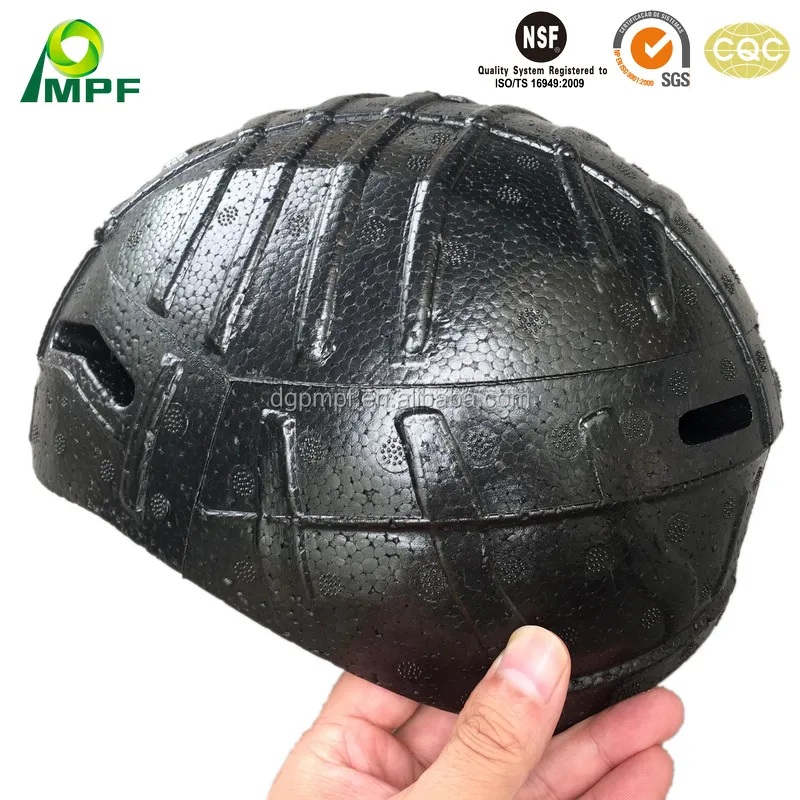

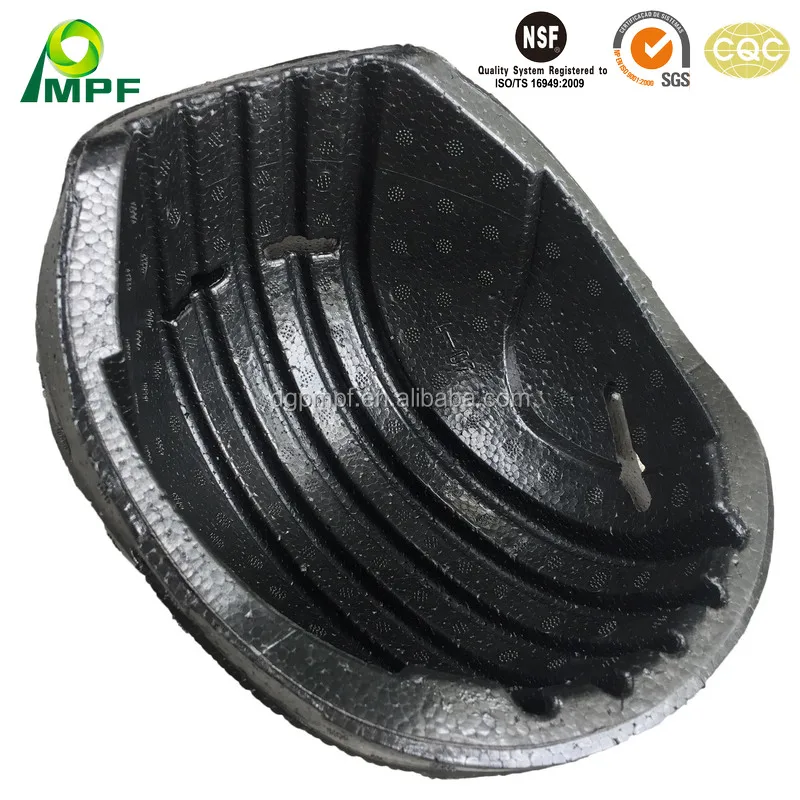

Противоударная ремонтная подкладка для лыжного шлема

- Категория: Лыжные шлемы >>>

- Поставщик: Dongguan City Duang L.M Co. Ltd.

Сохранить в закладки 60685277988:

Описание и отзывы

Характеристики

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

Why choose EPP

Most helmets today have liners made of EPS (Expanded Polystyrene), a great shock absorbing material, but it will be permanently compressed when absorbing an impact, even a minor one. Using multi-impact EPP (Expanded Polypropylene) as core material creates a helmet that will protect your head over and over again. To date, both traditional hard shell and in-mold helmets have relied on Expanded Polystyrene (EPS) for shock absorption. EPS absorbs energy by plastic deformation on impact and results in permanent deformation. As a consequence, a helmet liner made of EPS will not be as good absorbing repetitive impacts. It would be a trend that most bike helmets will use a liner of Expanded Polypropylene (EPP) instead of the traditional EPS. The difference between the materials is that EPP does not deform permanently, which means it's suitable for absorbing repetitive impacts.

EPP details

EPP is a plastic material with a wide range of applications and high engineering performances. Thanks to its specific properties, it can be used in various areas to improve technical performances and the absolute value of the end product.

\tResistant and non-deformable

EPP has a very high strength-to-weight ratio, with exceptional load bearing quality, reducing weight and volumes. Its high energy absorbing property makes it the ideal material to build, for instance, protection components in the automotive and logistic industry.

\tLightness

EPP is an ultra light material. It allows a significant weight reduction of the end product, with a substantial increase of resistance and efficiency.

\tAcoustic insulation

Porous EPP guarantees acoustic insulation, with excellent performances in the automotive industry.

\tThermal insulation

When temperature resistance is required, EPP provides thermal insulation: food, medical supplies and temperature sensitive products. EPP thermal insulation makes it the ideal material to be used in thermohydraulics.

\tRecyclable

EPP is 100% recyclable.

EPP Foam for Bicycle Helmet

During the last years there has been an increase in the number of applications of expanded polypropylene in the sports protection industry, to improve sporter's safety and performances.

Safety tests have shown the great ability of this polymer to absorb impact forces compared to traditional materials; besides its temperature resistance, its thermal and acoustic insulation properties and the possibility to be produced in every form and size, thanks to advanced moulding processes, make EPP particularly suitable for planning and producing a great number of helmets.

Packing: cartons

Delivery: 15~20 days after order confirmed.

Factory.

Our factory

Workshop.

Our workshop

Certificate of Registration

Environmental Management System Certificate

PMPF was established its name in the year 2010 and the factory is located in Chashan Town, Dongguan City, Guangdong Province, which covering a floor area of 15,000 square meters. With the factory be more and more stronger and the facility be improved to almost perfect, so we would like to improve our sales team and create a HK office to specialize in expand our sales global and promote our brand .

The PMPF products are widely used in an expanse of industries – from packaging solutions to automotive components, hobby models to foods, sports to engineering. The company is engaged in mould design, product research & development, special packaging material application and development. we are committing to the leadership of market trends, innovation and development and taking an active role in new eco-friendly high-end material's application of EPP,EPS,EPO and EPE.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Inferior-quality product will be recalled.

* Any problem will be solved ASAP.

Похожие товары

Длинные флисовые сетчатая подкладка новая разработка защитный шлем для катания на

Лучшее качество горячей оптовая продажа взрослых лыжи

Съемный комфорт внутри шлем для лыжного спорта

2018 новый стиль дамы горнолыжный шлем козырек

Оптовая Продажа ABS лыжный шлем, скейт сноуборд

Горячие продажи пользовательских горнолыжный шлем с системой регулировки

Самый популярный Сертифицированный высококлассный лыжный шлем для зимних видов спорта, катания на лыжах от производителя шлемов

Новые поступления

Новинки товаров от производителей по оптовым ценам