Лидер продаж новое состояние двухцветная машина для глубокой печати пластинчатого типа принтера с закрытым стаканчиком пластиковая мощная сердцевина двигателя

- Категория: >>>

- Поставщик: Lc Printing Industries Company LimitedLc Limited

Сохранить в закладки 60695663124:

Описание и отзывы

Характеристики

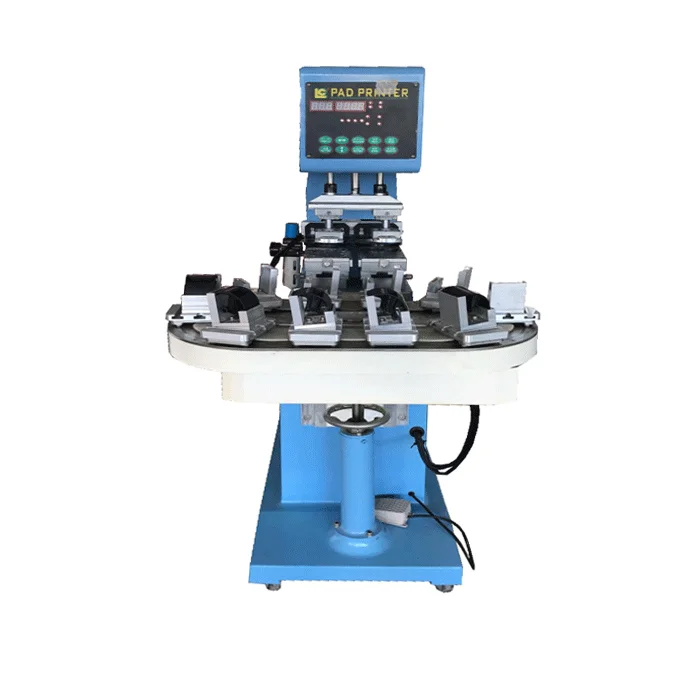

Pad Printing Machine for Plastic Products

There are many characteristics of the pad printing process: the adaptability of the printed matter is wide; there are many types of ink, and the pad printing ink and silk printing ink can basically be universal; the pad printing of different products can be easily completed by replacing fixture and printing block. The deformation of the rubber head has reached special products such as printing bowls, balls; grooves that can be printed, such as the inside of the rice cooker. The pad printer is one of the most widely used special printing machines. When you encounter a conventional machine that you cannot print it, you can consider using the pad printer.

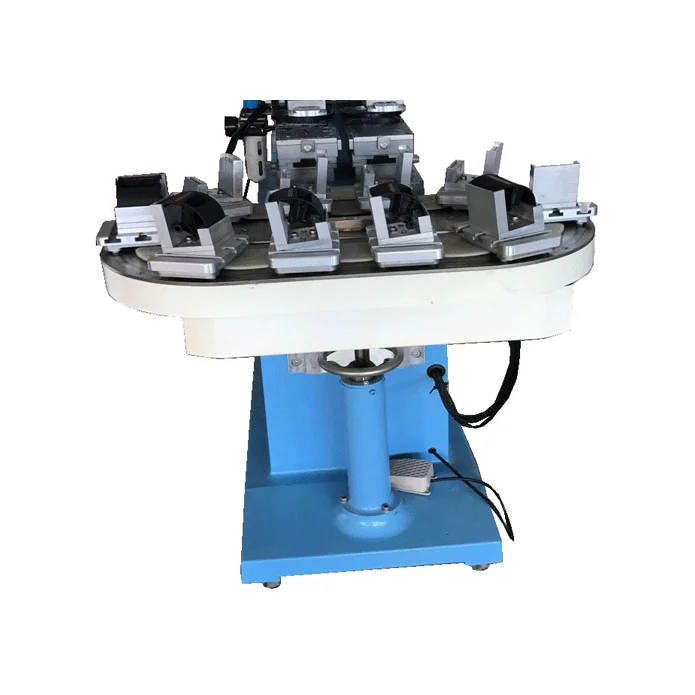

SPM2-150/10T Two colors pad printer with conveyer//Structure | |

Working table | 10 stations conveyer-type working table |

Shuttle stroke | 125mm |

Ink supply system | Closed -type system |

Plate type and size | 10mm Thick steel plate. Size :100*250mm. |

Pad dropping control | Simple-cylinder , simultaneously pressing |

Ink drying | Heat air |

SPM2-150/10T Two colors pad printer//Usage and characters | |

Guide |

|

Application fields | Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

SPM2-150/10T Two colors pad printer with conveyer //Parameter | |

Technical parameters | SPM2-150/10T Two colours sealed cup pad printer .

SPM2-200/10T Two colours sealed cup pad printer

|

Works supply |

|

Package list |

|

H.S.Code | 8443198000 |

Certicate | CE |

SPM2-150/10T Two colors pad printer with conveyer//Advantage | |

Function |

|

Machine photo

Catalogue

Printing factors

Flame treatment device + Two colors pad printer

PLC+Clean device + Two colors pad printer

1. What is a pad printer?

Pad printing machine is the machine, which uses an indirect printing process, it is very suitable for printing irregular surface of small products, make up for the lack of screen printing process, known as the screen printing twin sisters .

2 . The difference between the closed cup pad printer and open inkwell pad printer

The open ink-tray pad printer uses the ink-tray as the ink supply way, the ink is exposed to the air, the VOC is easy to volatilize to cause the air pollution, the ink-tray pad printers sells mainly to China, Asia, Africa and Eastern Europe and so on the environmental pollution request is not Too high a country;

The closed cup pad printer uses the closed cup as the ink supply way, the ink is enclosed in the cup, the VOC can not volatilize to the air, does not have the pollution to the environment basically, the closed cup pad printers sells mainly to Western Europe, On the environment demanding countries and regions.

3. Shuttle pad printer and Turntable pad printer

Shuttle pad printer is installed shuttle table printing machine, printing back and forth between the colors in the printing, shuttle printing machine can only print one product at a time, more accurate overprint, slower; and Turntable pad printer is installed Rotary table of the printing machine, a 10-station, 16-station, 22-station in various forms. Turntable pad printing machine stations are required to install the same product for printing, faster, no printing shuttle printing machine accurate.

4. Pad printing machine operating system

The ordinary printing machine adopts the microcomputer control system to carry on the control, the high-end pad printing machine uses the PLC to carry on the control, specially the servo control system pad printing machine or the automatic pad printing machine, uses the PLC control system quite commonly.

5. Pad printing machine movement characteristics

Most of the pad printing machine pneumatic control, slower, low cost. With the printing quality and printing speed of the user's high demand in recent years, the use of mechanical control of the pad printing machine more and more common. Pad printing machine automation is the most distinctive trend, the use of automatic feeding system, prepress processing device, servo drive system, automatic printing, drying machine as one of the mechanical and pneumatic motion perfect combination, greatly improving the productivity.

6. How to evaluate the quality of the pad printer

Pad Printing machine technology content is low, more and more enterprises began to produce and sell pad printing machines, pad printing machines of uneven quality, how to evaluate the quality of pad printing machine is essential. As the majority of brand-name pad printing machine is not sold through the network, so, through Alibaba sales of pad printing machines are low-end pad printing machine.

1) Design of the factory means: a special design department of the enterprise quality is more reliable. China has 70% of the pad printing machine manufacturing enterprises and no special design department, the development of new products on-site assembly by the basic, which is extremely adverse to the standardization of production machinery;

2) Processing means: CNC processing costs are higher, but the parts manufactured high precision; visit the factory must inspect whether the factory has CNC machining capacity;

3) Materials Selection: Material selection is very important. Now fierce competition, the vast majority of domestic factories in the selection of the above efforts, only the brand enterprises are willing to insist on the selection criteria above;

7. What is pad plate of pad printer?

8. How to make rubber pad of pad printer?

9. What is fixture of pad printer?

10.How to judge number color of pad printer?

11. How to choose pad printing ink?

- Printing machinery industry Alibaba 17 years golden supplier .

- 25 years of sales experience. areal understanding of customer need.

- Clearly marked price, earn consciencemoney. Profits no more than 20%.

The world is only one China, China only one LC, we are the production and sale of pad printing machines, silk screen machines, bronzing machines and automatic printing equipment and world famous!

Excellence in product quality depends on the high precision machining equipment;

The company has dozens of leading domestic CNC, printing machines, silk screen machines, bronzing machines and other special printing equipment, data and standardized management in the forefront of the domestic.Excellence in product quality depends on the high precision machining equipment.

All Machine has CE certification.

CE of pad printers

CE of screen printers

CE of hot foil stamping machine

CE of UV exposure machine and UV curing machine. Etc

1) What are your main products?

Pad printers,

Silk screen printers,

Hot stamping machines,

and the supply chain related to the above-mentioned industrial printing, we will also provide users with complete printing solutions.

2) What kind of pre-sale service do you provide.

Free technical consultation, pictures, technical materials, and video materials are provided. For those that cannot be provided, we may provide design solutions.

3) What kind of payment method should I choose?

For new users, if the amount is smaller, you can use the credit guarantee order, TT, and if the amount is larger, you can consider a letter of credit. In order to protect the safety of customers' funds, we do not recommend customers to transfer to personal accounts, or use Western Union, paypal and other personal payment methods. Unless the customer makes a special request.

4) How to order the machine?

When you confirm to buy the machine, we will provide PI, and pay according to the payment method guided by PI. We will produce the machine and arrange the calculation until you get the machine safely.

5) Questions about proofing?

For direct users, it is very important to confirm whether the machine is suitable for their products and require the factory to carry out proofing as the standard for machine delivery, because pad printing machines, screen printing machines and hot stamping machines usually require fixtures, printing plates, and inks. The perfect match of the bronzing paper can meet the requirements. For the proofing of the customer's confirmed order, we are free. For the proofing without the confirmed order, we will charge a certain proofing fee. When you confirm the order, the proofing fee will be deducted from the machine purchase price.

6) How about after-sales service?

Companies that sell through the Internet are usually small in scale, and none of them have set up after-sales service points overseas. After-sales service requires online support from sales staff. In general, pad printers, screen printers and hot stamping machines are relatively simple machines, and most problems can be solved through online communication.

7) How do you evaluate the quality of your products?

When each user purchases a product, he balances price and quality. This balance may be difficult to grasp, but this is how you do business. Most of the products sold on the Internet are in the middle of whether the price is not low or the quality is not bad. end. You have to negotiate professionally with the sales staff for better products. There are roughly 300 similar manufacturing plants and more than 8,000 trading companies in China. It is not difficult to choose products that suit you.

Похожие товары

Двухцветная печатная машина для пластиковых подушечок

2-х цветный на теннисном мяче тампонный принтер ручной тампонная печатная машина

Автоматический станок для тампонный печати на бутылках ЛИДЕР ПРОДАЖ

Лидер продаж DY-8 портативная машина для печати кодов даты кодирования срок действия которой истек на сумке/карточке/бумаге

Небольшой принтер с вибрационным диском для пластиковых деталей

Дешевый пэд-принтер для часов 1 цвет

Высококачественный 1 цветной принтер с подносом для чистых чернил и чашкой высокого давления

Новые поступления

Новинки товаров от производителей по оптовым ценам