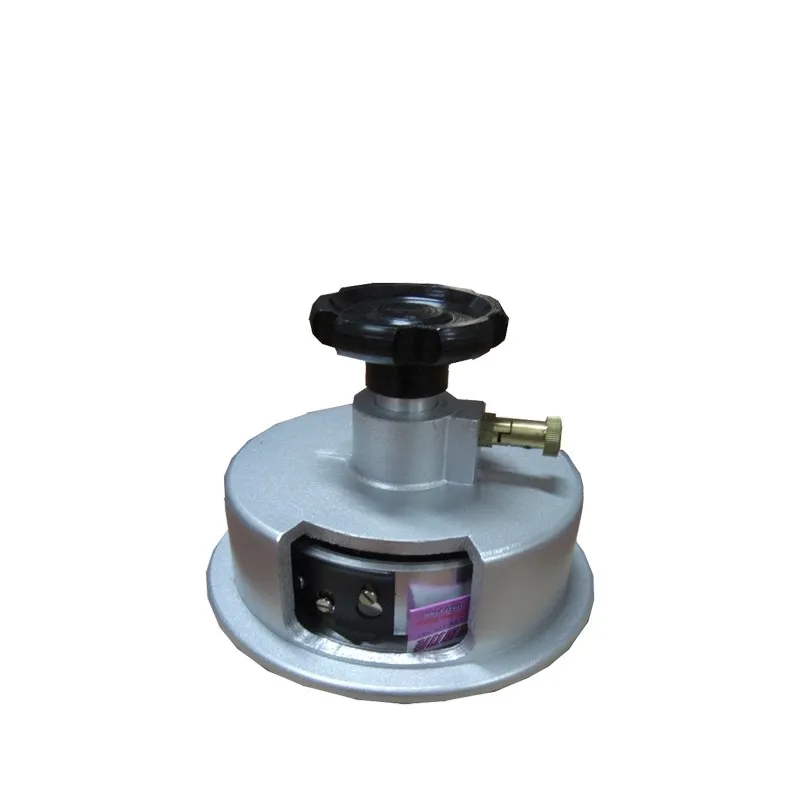

Твердосплавное керамическое уплотнительное кольцо SSIC для механического насоса

- Категория: >>>

- Поставщик: Xiamen Mascera Technology Co. Ltd.

Сохранить в закладки 60700222729:

Описание и отзывы

Характеристики

Silicon Carbide Ceramic has excellent mechanical strength and hardness, small creep deformation, good oxidation resistance, good corrosion resistance and good wear resistance, it is an ideal choice for high temperature engineering materials. Due to the outstanding properties, Silicon Carbide Ceramic is also recognized as a mechanical sealing material better than metals, tungsten carbide, al2o3 ceramics etc. Moreover, it also has advantages of self-lubricating properties and low friction coefficient.

According to the different manufacturing methods, the materials below are avaible:

Sintered Silicon Carbide (SSiC)

Reaction Bonded Silicon Carbide (SiSiC)

Typical Properties

✔High strength in high tempperature

✔High-temperature oxidation resistance

✔Excellent wear resistance

✔Low thermal expansion and high thermal conductivity

✔Excellent thermal shock resistance

✔High Hardness

✔Outstanding corrosion resistance

Application Examples

✔Mechanial seal rings

✔Balls, seats, liners for valve

✔High Temperature kiln furniture

✔Heat exchangers

✔Fixed and moving turbine components

✔Components for burners

✔Ceramic bearings

Properties | Unit | SSiC | SiSiC |

Color | - | black | black |

Density | g/cm3 | 3.12 | 3.06 |

Water Absorption | % | 0 | 0 |

Vickers Hardness | Gpa | 25 | 22 |

Flexural Strength (R.T.) | Mpa | 400 | 300 |

Compressive Strength (R.T.) | Mpa | 2500 | 2000 |

Thermal Conductivity (R.T.) | W/m.k | 130 | 100 |

Thermal Shock Resistance | △ T(℃) | 350 | 220 |

Max. Working Temperature | ℃ | 1500 | 1300 |

Alumina Ceramics

●Strong wear resistance

●Good electrical insulation

●High temperature resistance

●High mechanical strength

Zirconia Ceramics

●High fracture strength

●Strong wear resistance

●High durability and hardness

●Similar CTE with steel

Boron Nitride Ceramics

●High temperature resistance

●High thermal conductivity

●Non-wetting with metals

●Good electrical insulation

Silicon Nitride Ceramics

●High Fracture Strength

●High Strength in a wide temperature range

●Strong wear resistance

Silicon Carbide Ceramics

●High Strength in a wide temperature range

●High thermal conductivity

●Good thermal shock resistance

Aluminum Nitride

●Very high thermal conductivity

●High mechanical strength

●Good electrical insulation

●Similar CTE with Si

We have completed production lines for molding, sintering, high precision machining, quality inspection of technical ceramic components. Our products are in conformity with ISO9001:2015 quality management system and we are capable to deliver ceramic components of fully dense, accurate size and surface finish control, prompt lead time.

Since our foundation, Mascera has committed to providing ceramic components of highest quality and has built faithful partnership with our customers. Currently, our products have been exported to more than 30 countries and widely applied in industries like machinery, automotive, chemistry, medical, energy, electronic, semiconductor, aerospace, telecommunication etc.

A: MOQ will differ in material, size, machining difficulty, we will let you know MOQ for each part when inquiry.

Q2: Can i get a sample for test?

A: For ceramic parts we have in stock, we can provide free sample if goods value is not high; for ceramic parts which is newly developed, mold cost or sample cost will be needed.

Q3. Can you produce according to the samples or drawings?

A: Yes. most of our ceramic parts are customized, we have rich experience in tailor-made parts. We have capability to control the parts in required size accuracy and surface finish

Q4. How can i pay to you?

A: We accept payment of T/T, credit card, Western Union, Paypal.Payment terms is 50% payment in advance and 50% before shipment.

Q5. Can i get a replacement for damaged or defected products?

A: Yes, we will remake new products for you when damage or defect are found, if you could not wait for extra time, we will refund to you or issue a credit to use in future orders.

Похожие товары

Запасные части для двигателя для грузовиков, категория 2

Тактический складной карманный нож для выживания охоты кемпинга Быстрое открытие G10 ножи из дамасской стали

Ручной тип высокое качество суши рулонная машина для резки нержавеющей стали суши-ролл резак

Электростанция, широко используемая дробилка для древесины, дробилка для древесных бревен

Новый блок двигателя IFOB YD22 для Nissan A mera Sedan (N 16) 2,2 d Ci

Jinan aoyoo дешевый 1625 планшетный автоматический Осциллирующий нож для резки гофрированного картона cnc цифровой промышленный резак для бумаги

China top digital cutting machine shoe pattens cutting digital cutting machine shoe pattens cutting cutting leather machine

Новые поступления

Новинки товаров от производителей по оптовым ценам