ELITEWHEELS дилер UNI легкий вес 1330 г Углеродные велосипедные колеса 45 мм Глубина с керамическим подшипником 700c колесная пара

- Категория: >>>

- Поставщик: Xiamen Yuan An Composit Technology Co. Ltd.

Сохранить в закладки 60705766018:

Описание и отзывы

Характеристики

![1830-202108031002270720[1].jpg](https://sc03.alicdn.com/kf/Hd3113b64d955494491e95237eeaf7c20T/220410448/Hd3113b64d955494491e95237eeaf7c20T.jpg)

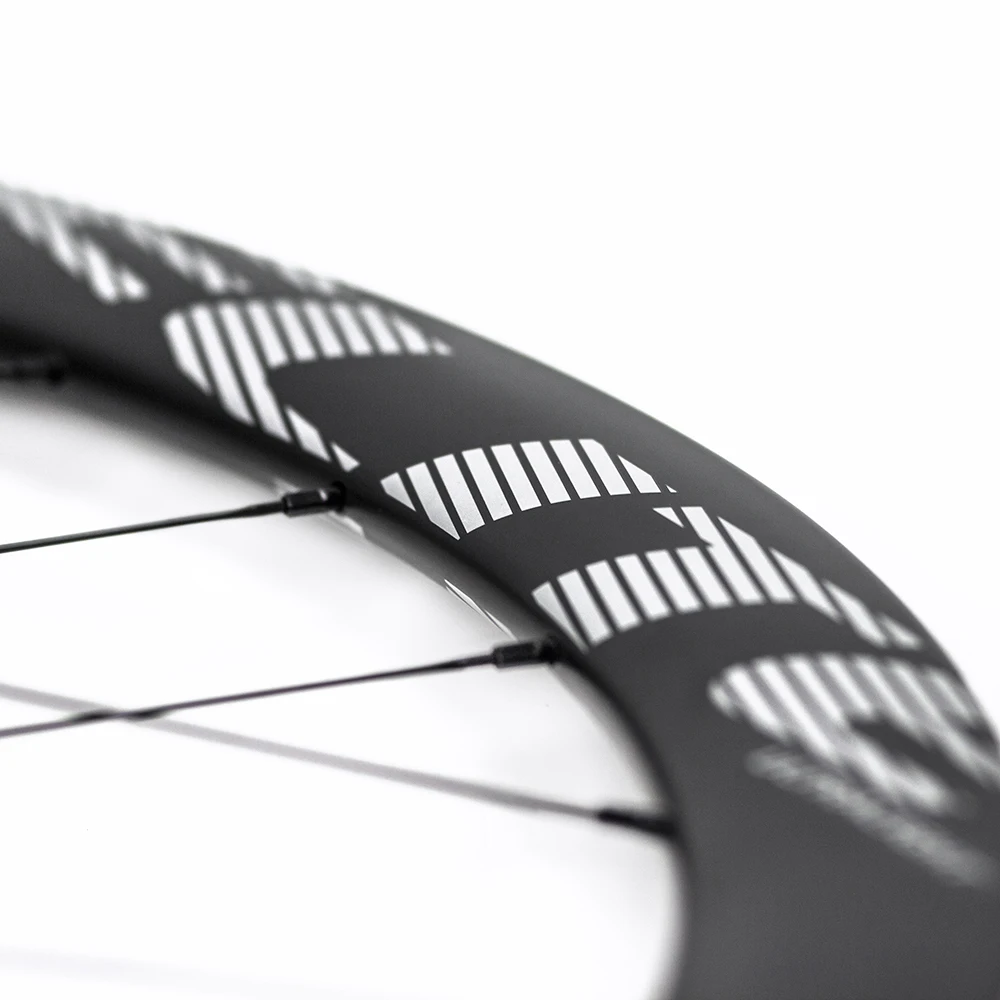

The UNI wheelset

Ceramic Bearings

The UNI wheelset standard use use S&S ceramic bearings both front and rear hubs ,ceramic bearings further increase hub rolling efficiency with lower rolling resistance.At the same time, the non-driving side of the front and rear hubs have bearing pre-tightening side covers.

Performance hub

The front and rear hubs use 6902 bearings. The larger the bearing, the better the rigidity. On the premise of ensuring the performance output of the hub, we try to reduce the weight on the hub body and minimize the rolling resistance.The front hub has 21 spokes,14 on the drive side and 7 on the non-drive side

The rear hub has 24 spokes, 16 on the drive side and 8 on the non-drive side.

Such a combination of spokes makes the spoke tensions of the front and rear wheels, the driving side and the non-driving side more balanced, and can more accurately control the direction when crossing a curve at high speed.

Tubeless compatible

All UNI wheel series are tubeless compatible, if you want to use tubeless tire, we will be equipped with tubeless rim tape and tubeless valve.

High TG brake sufrace

Standard use SAPIM CX RAY spokes.both front and rear wheels use 2x cross lacing.hand-built wheel.each spoke has 16 tension releases.the deflection of the wheel is guaranteed to be within 0.2mm.

Parameter

| UNI E45 | ||||

| RIM | SPOKE | |||

| SERIES: | UNI E45 | FRONT SPOKE PATTERN: | 2x cross | |

| RIM TYPE: | Tubeless compatible | REAR SPOKE PATTERN: | 2x cross | |

| RIM DEPTH: | 45mm | SPOKE COUNT: | 21F/24R | |

| INNER WIDTH: | 21mm | SPOKE TYPE: | Sapim cx ray | |

| OUTERWIDTH: | 28mm | NIPPLE TYPE: | Sapim Secure Lock | |

| HUB | OTHER | |||

| FRONT HUB: | 12*100 ceramic bearing | ASSEMBLY METHOD: | Handbuilt | |

| REAR HUB: | 12*142 ceramic bearing | EXTRAS: | Tubeless rim tape,Valve | |

| BRAKE INTERFACE : | Center lock | WEIGHT: | F.590g R.740g | |

| HUB TYPE: | YAn RD28 | SYSTEM WEIGHT LIMIT: | 275lbs / 125kg | |

| CASSETTE BODY: | SHIMANO&XDR | RECOMMENDED TYRE: SIZES | 25 to 43mm | |

Extra parts

About UNI.

After two years of continuous experimentation on lighter carbon fiber materials and the research and development of resins by the yuan an bike team, a set of optimal material ratios was finally reached.This is between T800 and T1000 of Toray..this is the composition table of the special materials used in T800, T1000 and UNI.you can see its tensile strength, the tensile modulus should be more balanced.

![1830-202108201426578637[1].jpg](https://sc03.alicdn.com/kf/H1a660b9fc79244548e7c581e1f3f85e7T/220410448/H1a660b9fc79244548e7c581e1f3f85e7T.jpg)

In all the test values, the strengths of UNI are better than those of rims made of ordinary materials.

*All test data are from Yuan'an laboratory

1. Lateral Stiffness

Lateral stiffness in a rim speaks to the level of movement from side to side. Laterally stiff rims feel more responsive during powerful accelerations like sprinting,Power transfer value is more efficient. a direct power transfer. Also, steering and handling feel sharper.

Under the max load of 50kgf, the UNI 45-03 deforms 9.07mm, with an increase of 22% in lateral stiffness compared to a same-deep 45-01 rim (11.65mm deformation).

![1830-202108201429060456[1].jpg](https://sc03.alicdn.com/kf/H52686d682c824014a5df69a2452b0b5bN/220410448/H52686d682c824014a5df69a2452b0b5bN.jpg)

2. positive Stiffness

The positive Stiffness indicates the range of weight that the rim can bear. Under different tire pressures and different rider weight conditions, any slight deformation of the rim directly affects the rolling coefficient of the rim and tire. Under the premise of ensuring the maximum load-bearing capacity of 130kg, riding through any road conditions can ensure that the rim is intact and rolls well.

Under the max load 300kgf,the UNI 45-03 deforms 8.2mm.with an increase of 10% in positive Stiffness compared to a same-deep 45-01 rim(9.06mm deformation)

![1830-202108201429583424[1].jpg](https://sc03.alicdn.com/kf/H562c6660bbb943899281350c0595bf24v/220410448/H562c6660bbb943899281350c0595bf24v.jpg)

3. Spoke hole tension

The best spoke tension value is to ensure excellent rigidity requirements without excessive vibration. The test values of UNI 45-03 and same-deep 45-01 are very close, both are 340kgf. Therefore, it can be proved that the lighter spoke hole wall thickness design will not reduce the tension of the spoke hole.

![1830-202108201430173380[1].jpg](https://sc03.alicdn.com/kf/H49db67f38d844a97b4a6b2e9232e3ab79/220410448/H49db67f38d844a97b4a6b2e9232e3ab79.jpg)

4. Impact Resistance

Under UCI's test standards, we conducted 24 impact tests, one impact at the corresponding position of each spoke hole, and the rim was still intact after 24 impacts.

![1830-202108201430491751[1].jpg](https://sc03.alicdn.com/kf/H8517a4586277442b9e97077d9002521cS/220410448/H8517a4586277442b9e97077d9002521cS.jpg)

Lighter and stronger wheels are always our pursuit. Different rim shapes determine the aerodynamic performance of the wheels. More importantly, the competition wheels are focused on the most basic things. Power transmission and low loss performance depend on the rigidity and lightweight of the rim. Of course, hubs and spokes are also crucial factors.

The lighter, more rigid wheels can accurately control the angle of entry when cornering at high speeds, and the wheels can react quickly when sprinting to help you win.

These are the original purposes of our research and development of UNI.

For the UNI series wheels, 30 layers of carbon cloth are used to supplement the strength requirements at the main force position of each spoke hole. In the redundant position between the left and right spoke holes, we only use 15 layers of carbon cloth for reduction. Re-optimize processing. It not only guarantees the tension requirement of the spoke holes but also reduces the excess weight.

![1830-202108201431537650[1].jpg](https://sc03.alicdn.com/kf/Hd4474ec6bdbd411ea38267e8a2b354e1Z/220410448/Hd4474ec6bdbd411ea38267e8a2b354e1Z.jpg)

UNI's wider design, the inner width reaches 21mm, and the tire can use 700*25C~700*43C. It can meet more riding needs.

The left and right angles of each hole inside the spoke holes can reach 8.2°, and the angle of the upper and lower spoke holes can reach 3.4°, which can meet the angular demands of more large flange hubs of road disc brakes.

Not only that, on the premise of ensuring the tension of the spoke holes, we also need to consider the side rigidity of the rim. High-power input requires not only high spoke tension transmission, but also sufficient rigidity of the rim to be transmitted to the tire to roll. Therefore, we added 2.5cm wide T800 carbon fiber on the side of the spoke hole. Therefore, the side rigidity has been increased by 30%, which has a better transmission value than ordinary weight wheels.

Therefore, the UNI series is the lighter, stronger and more perfect rim you need.

TECHNOLOGY

CHA/Customized spoke hole angle

All spoke hole angles must be customized according to the geometric angle of the hub.all drilled holes are inspected to ensure they are free of burrs.You can request a customized drilling pattern if you have a unique wheel build.

TRD/Tubeless R angle design

All elitewheels are tubeless compatible.We design a R angle,The rounded edge makes tire installation easier and offers increased support during hard cornering with a softer edge and larger surface area.

LMS/lighter materials improve the strength

We use lighter materials and make full use of the combination of T700 and T800 to improve the strength.

SIW/smooth Inside Wall

We use a specific, thinner, high-pressure air bladders to control the inner wall smoothness, and the inner wall air bladders can be extracted clean at one time, without residue, not only effectively improve the tightness of the carbon fiber yarn, but also allow the spoke cap to be more tightly integrated with the spoke hole

OPT/one piece technology

Compared to the technology of 3 piece, our one piece tech is more technically difficult and takes longer to produce, but the rigidity of the rim is at least 7% higher

BLT/Bead Lock technology

The bump on the rim bed helps to create a buffer during tire inflation, making the mounting process easier. When the tire is mounted, the raised portion reinforces the tire bead, making it harder to “burp” or fall back into the drop channel.

Design your brake surface?

Basalt brake surface or crystal polishing brake surface.

What is the role of basalt braking surface?

Basalt is a special carbon fiber material, the surface is rough and high temperature resistance, wear-resistant.

Basalt has a good performance, both on dry and wet roads.

What is the difference between UD, 3K, and 12K Weaves?

The weave patterns you see on some of our rims are only the external layer and are done for cosmetic reasons.

This layer utilizes the same resin system as the rest of the rim and so the weight and performance are not significantly changed. UD is the most popular option.

What is the role of crystal polishing brake surface?

Crystal polishing is a special technology, in the final steps of the machining rim, we use crystals to polish the surface of the braking surface, so that the surface of the braking surface has better flatness, thus increasing the wear resistance of the brakes, also effectively avoid the noise when braking. Crystal Polishing is only a technology, not a specific individual refers to a type of braking surface, ud/3k/6k/12k braking surface all can be used with crystal polishing this technology .

Похожие товары

Рыболовный трос, буксир, небольшая подъемная тянущаяся гидравлическая лебедка для крана, эвакуатора, лодки для рыбалки, трала

Оригинальный прямой ход DriverEMGA-40-P-G5-SST-42 549429 для FESTO

Промышленная вентиляция 250FZY7-D 380 В переменного тока, вытяжной Осевой поток, вентиляторы радиатора для сварочного аппарата

Мужская Трикотажная куртка на пуговицах, с высоким воротником, на весну и осень, кардиган, свитер

510-8095 Запчасти для экскаватора двигатель вентилятора для экскаватора E320 E323 E329 E336 E320GC E336GC E340 E349 M317 M318 M319 M320 MH3040

Горячая Распродажа, 1,3 галлонов, прямоугольная ступенчатая мусорная корзина из нержавеющей стали, корзина для мусора с мягкой педалью для комнаты

Настольная роликовая машина для высечки картонных коробок

Новые поступления

Новинки товаров от производителей по оптовым ценам