OEM Изготовленные На Заказ запасные пластиковые части для дрона вертолета литьевая пресс форма высокого качества

- Категория: >>>

- Поставщик: Shenzhen Abery Mold & Plastics Co. Ltd.

Сохранить в закладки 60713318758:

Описание и отзывы

Характеристики

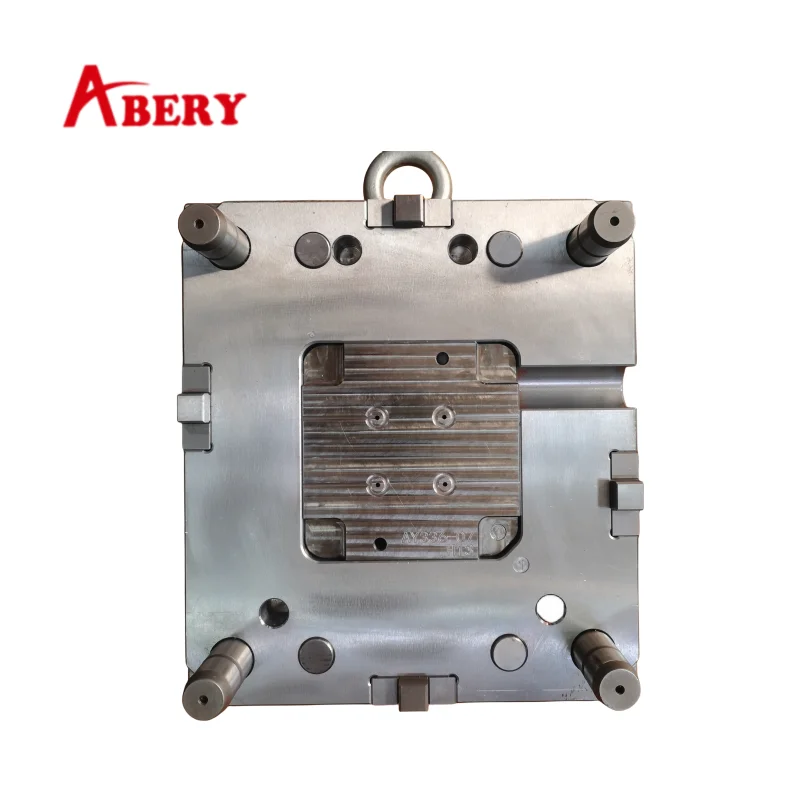

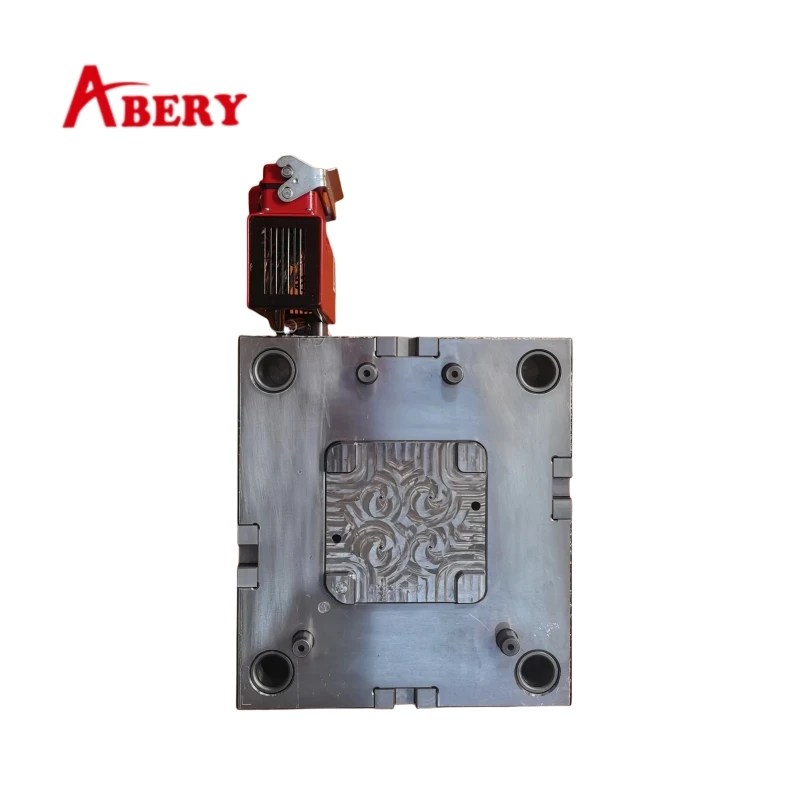

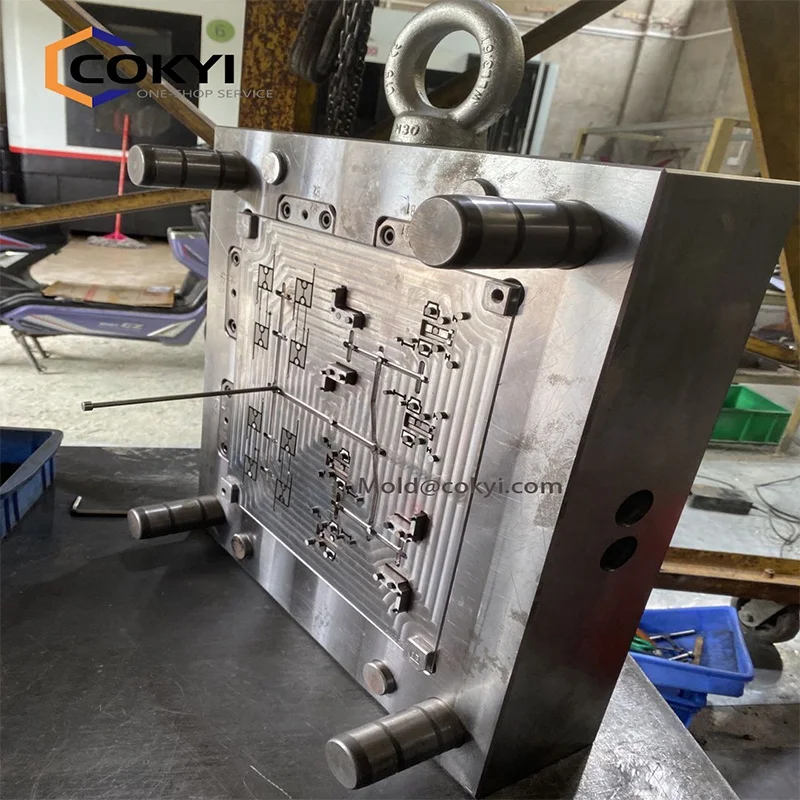

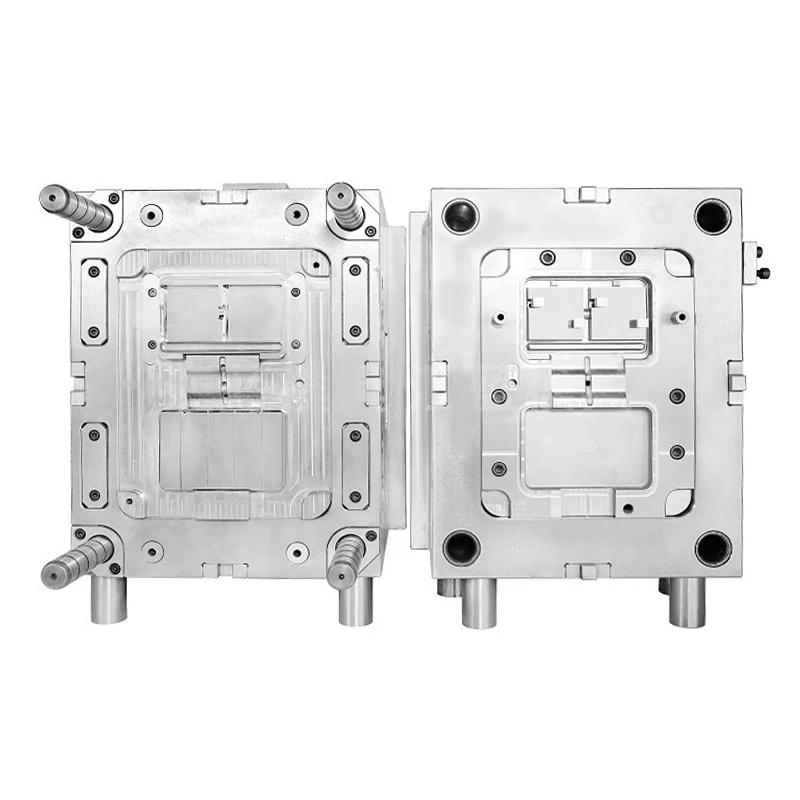

OEM customized drone helicopter spare plastic parts injection mold with high quality

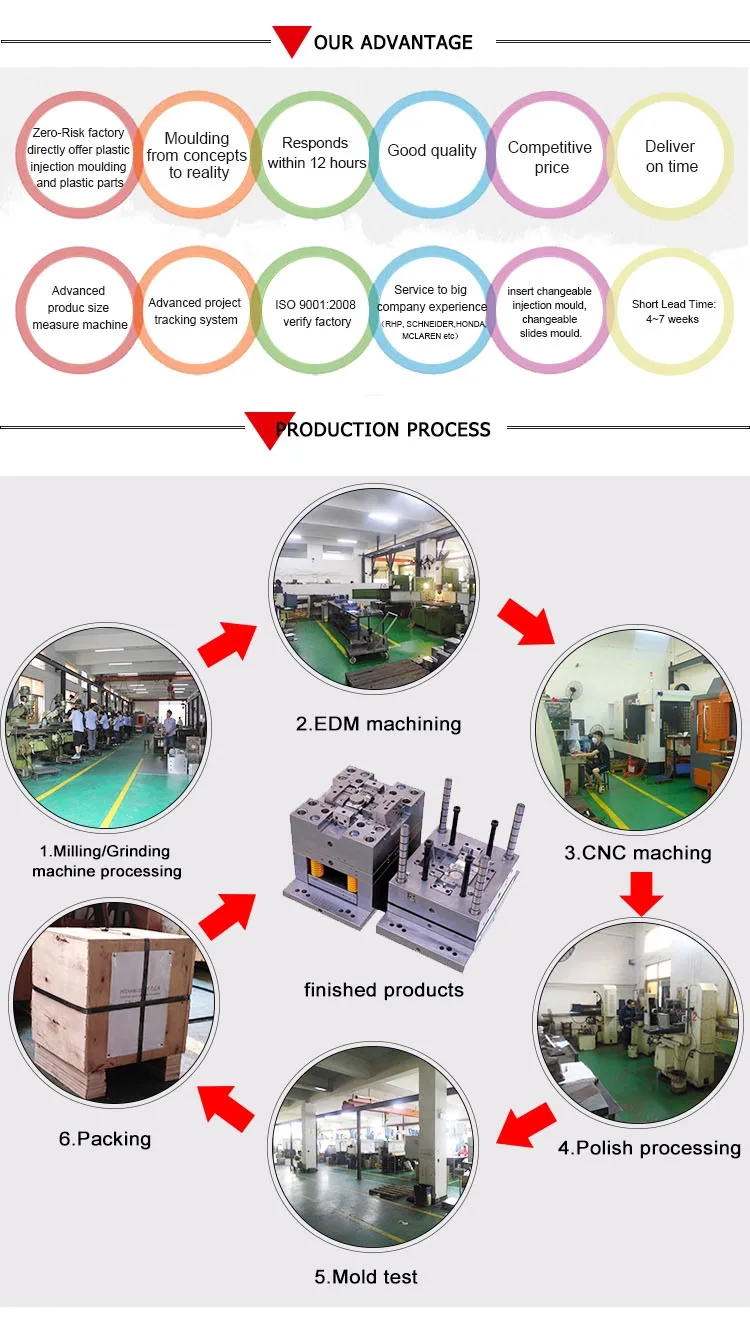

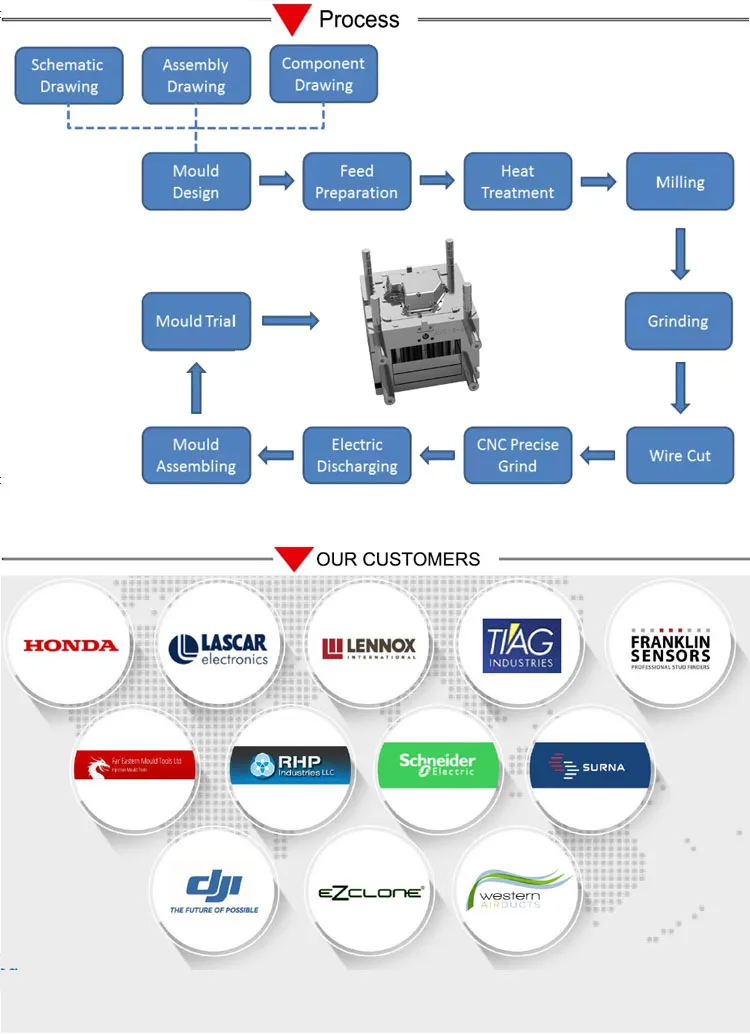

Our service:

1. Parts Design ,Prototype, Vacuum Casting for small quantities

2. R&D (Design according to client's drawing and requirements ). Mould Manufacturer with DME, HASSCO Standards, Export to France ,Italy, Norway, USA, Israel and so on. Professional mold manufacturer with 15 years

3. Molding parts, such as car parts, auto accessories, electronic components

Basic specification:

Mould Type | Plastic Injection Mold |

Design Software | UG, ProE, Auto CAD, Solidworks, etc. |

Mould Material | 718H, P20, NAK80, S316H, SKD61, etc. |

Hardness of the steel | 20~60 HRC |

Mould Base | HASCO, DME, LKM, etc. |

Runner | Hot runner, Cold runner, as per customers requirement and part structure. |

Mould Cavity | Single-cavity or Multi-cavit, as per customers requirement and part structure. |

Ejection Techniques | Pin ejection, sleeve ejection, bar ejection, blade ejection, etc. |

Gate Type | Edge gate, sub-gate, pin gate, side gate, etc. |

Mould hot treatment | Quencher, Nitridation, Tempering, etc. |

Mould Cooling System | Water cooling or Beryllium bronze cooling, etc. |

Mould Surface | EDM, texture, high gloss polishing |

Mould Life | >500,000 shots |

Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder, Lathe, Milling machine, plastic injection machine |

Raw material of plastic injection | PP, PA6, PLA, AS, ABS, PE, PC, POM, PVC, PET, PS, TPE/TPR, etc. |

Lead time | 25~60 days |

Certificate | ISO 9001:2015 |

Packaging:

Usually ,we use the plywood case for mold, paper box for the plastic parts,

If you have special requirements ,pls tell us , we will do them for you.

Shipment:

transport by sea or air

FAQ:

Q. When can I get the price ?

A. We usually quote within 24 hours after we got your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

Q. How can I get the accurate price ?

A.There are some basic specs we need to know for price calculate, that are: 3D drawings in STP,IGS,X-T format are avaialble, Please suggest us your quantity too.

Q. Do you accept the OEM?

A. OEM is welcome. We can custom the good according to your design.

Q. What is the shipping ?

A:By express(FedEx, UPS, DHL, TNT, EMS, etc...),By Air,by shipping.

Q. How do i pay for the order?

A.The common payments are T/T(Telegraphic Transfer),western union ,

Q. I have an idea for a new product, but don't know if it can be manufactured. Can you help?

A. Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Q. What are the advantages to having my parts manufactured locally?

A. offer quick reaction times to any changes in specification, batch size or material. We can ship small or large quantities anywhere in Europe overnight to accommodate unforeseen changes in demand.

Q. My components have already been developed on CAD. Can you use the drawings?

A. Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used to generate quotes, models and mould tools - this can save time and money in producing your parts.

Q. Can I test my idea/component before committing to mould tool manufacture?

A. Yes, we can use CAD drawings to make models for design and functional evaluations.

Q. What type of plastic is best for my design/component?

A. Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

Q. What type of mould tool do I need?

A. Mould tools can be either single impression (one part at a time) or multi-impression (2,4, 8 or 16 parts at a time). Single impression tools are generally used for small quantities, up to 10,000 parts per year whereas multi-impression tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q.Ok, I've decided to go ahead with my project. How long will it take to get my parts?

A. It can take 3-8 weeks to have the mould tool manufactured depending on the part's complexity and the number of impressions (single or multi). After we have received final approval by you of the new tool, you can expect delivery of parts within 2-3 days.

Похожие товары

Dongguan лидер продаж высокое качество строгий допуск на заказ прецизионные детали штамп с кодом даты календаря

Пластиковая форма для литья под давлением рефлекторный отражатель Bmc автомобиля грузовика мотоцикла скутера фары с оптикой Заводская

Декоративные молдинги в виде римских колонн

JCM004 Китай плесень высокой точности литья под давлением производитель

Изготовленный на заказ Авто Запчасти для легковых автомобилей запчасти бампер/капюшон/крыши/задняя часть заднего палубы/задний четверть/двери/кранцы/фар литья пластмасс под давлением

Высококлассная профессиональная машина для литья под давлением пластиковых бамперов автомобильного бампера

Стальная форма для проверки бетона состоит из сборного и железных компонентов

Новые поступления

Новинки товаров от производителей по оптовым ценам