Литая шлифовальная хромированная углеродистая сталь

- Категория: >>>

- Поставщик: Jinan Huafu Forging Joint-Stock Co. Ltd.

Сохранить в закладки 60715095145:

Описание и отзывы

Характеристики

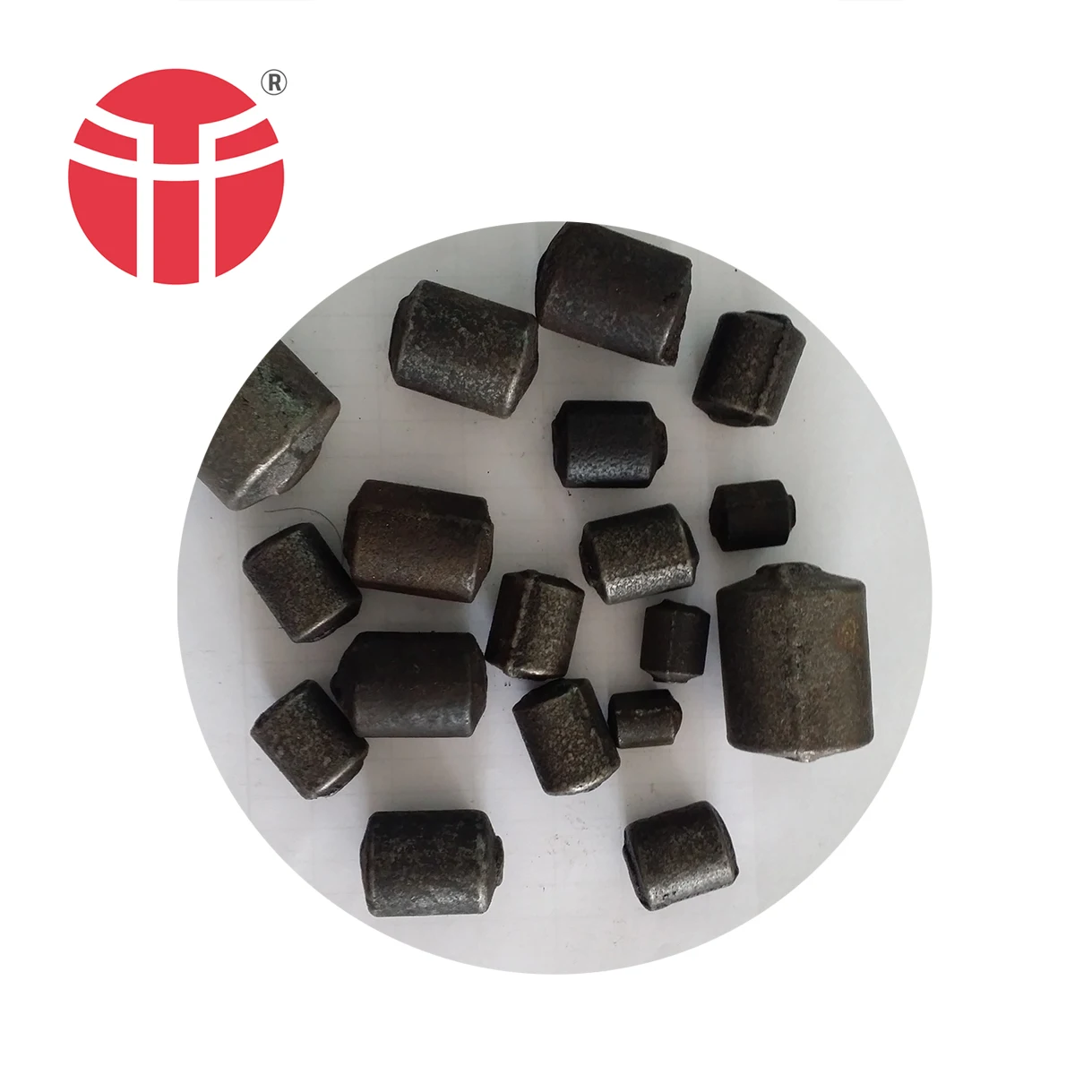

high chrome cast iron cylpebs for mine

Our products having been produced strictly according to the ISO9001:2015 quality standard and are mainly used in mines, cement plants, building materials, power stations, chemical industry and steel mills, Well sold across China and exported to the United States, Chile, the UK, Brazil, South Africa, Australia, South Korea, India, Russia, Mexico, Malaysia, Laos, Vietnam and other dozens of countries and regions, our products got highly appreciated by our customers.

1. Diameter

| Diameter (mm) | 20×25mm | 25×30mm | 30×35mm | 35×40mm | 40×45mm | 45×50mm | 50×55mm |

2.Chemical composition

Brand | C(%) | Si(%) | Mn(%) | Cr(%) | Cu(%) | Mo(%) | P(%) | S(%) | Ni(%) |

45# | 0.42-0.50 | 0.17-0.37 | 0.5-0.80 | 0-0.25 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

60Mn | 0.57-0.65 | 0.17-0.37 | 0.70-1.0 | 0-0.25 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

65Mn | 0.62-0.70 | 0.17-0.37 | 0.90-1.0 | 0-0.25 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

U71MN | 0.65-0.76 | 0.17-0.37 | 1.10-1.40 | 0-0.25 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

40Cr | 0.37-0.45 | 0.17-0.37 | 0.50-0.8 | 0.80-1.1 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

42CrMo | 0.38-0.45 | 0.17-0.37 | 0.50-0.80 | 0.80-1.2 | 0-0.03 | 0.15-0.25 | 0-0.035 | 0-0.035 | 0-0.30 |

70Cr2 | 0.65-0.75 | 0.20-0.30 | 0.75-0.90 | 0.55-0.70 | 0-0.25 | 0-0.30 | 0-0.030 | 0-0.030 | 0-0.30 |

40Mn2 | 0.37-0.44 | 0.17-0.37 | 1.4-1.8 | 0-0.25 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.30 | 0-0.30 |

B-2 | 0.70-0.80 | 0.17-0.37 | 0.70-0.80 | 0.40-0.60 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

B-3 | 0.58-0.66 | 1.2-1.8 | 0.65-0.80 | 0.70-0.90 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

B-4 | 0.60-0.65 | 1.6-1.7 | 0.7-0.8 | 0.7-0.8 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

B-6 | 0.75-0.85 | 0.2-0.40 | 0.9-1.0 | 0.85-0.95 | 0-0.25 | 0.06-0.13 | 0-0.035 | 02-0.035 | 0.06-0.13 |

B-6A | 0.82-0.95 | 0.20-0.40 | 0.92-1.02 | 0.80-0.95 | 0-0.25 | 0.06-0.10 | 0-0.035 | 0-0.035 | 0.06-0.10 |

B-7 | 0.35-0.40 | 0.17-0.37 | 0.7-0.8 | 0.9-1.0 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

BU | 0.95-1.05 | 0.17-0.37 | 0.9-1.10 | 0.40-0.60 | 0-0.15 | 0-0.05 | 0-0.035 | 0-0.035 | 0-0.30 |

3.Technical specification

Brand | Breakage rate | Hardness (HRC) | Impact value (J/cm²) | Drop times | Micro structure |

45# | <1% | ≥45 | ≥12 | ≥8000 | M+C |

60Mn | <1% | ≥55 | ≥12 | ≥12000 | M+C |

65Mn | <1% | ≥58 | ≥12 | ≥12000 | M+C |

U71MN | <1% | ≥58 | ≥12 | ≥12000 | M+C |

40Cr | <1% | ≥55 | ≥12 | ≥12000 | M+C |

42CrMo | <1% | ≥55 | ≥12 | ≥12000 | M+C |

70Cr2 | <1% | ≥58 | ≥12 | ≥12000 | M+C |

40Mn2 | <1% | ≥55 | ≥12 | ≥12000 | M+C |

B-2 | <1% | ≥58 | ≥12 | ≥15000 | M+C |

B-3 | <1% | ≥60 | ≥12 | ≥15000 | M+C |

B-4 | <1% | ≥60 | ≥12 | ≥15000 | M+C |

B-6 | <1% | ≥60 | ≥12 | ≥15000 | M+C |

B-6A | <1% | ≥60 | ≥12 | ≥15000 | M+C |

B-7 | <1% | ≥60 | ≥12 | ≥15000 | M+C |

BU | <1% | ≥60 | ≥12 | ≥15000 | M+C |

20mm-40mm hot rolling steel ball production line

40mm-60mm hot rolling steel ball production line

2)80mm-120mm Semi automatic production line of hot forging steel ball

Cutting raw material→furnace heating→forging→enter into rolling ball machine→Isothermal system→quenching system→steel ball sweltering self tempering device→finished product steel ball

3)Traditional production line of forged steel ball

Cutting raw material→furnace heating→forging→Isothermal system→quenching system→steel ball sweltering self tempering device→finished product steel ball

| Packaging | Diameter | Weight |

| Bag | 17-150mm | 1000kg/bag |

| Drum | 15-20mm | 1000kg/drum |

| 25-30mm | 950kg/drum | |

| 40-60mm | 900kg/drum | |

| 70-100mm | 850kg/drum | |

| 110-150mm | 800kg/drum | |

| Container | 17-150mm | 25tons |

We mainly produce grinding media in ball mill for many years. Jinan Huafu Forging Co., Ltd is located in Zhangqiu

City, Shandong Province, 45 Kilometers to the Jinan downtown, next to the 309 National Highway, enjoying

firsthand Information and convenient traffic. Our company covers 80000 square meters, with over 100 employees,

annual production capacity of 100000 tons and registered capital of seventy million yuan.

We mainly produces forged steel balls, cast iron balls, steel cylpebs, grinding rods, mill liners, steel, hammer heads, automatic production lines for steel balls & grinding rods and decorative wrought iron products.We have ability to

produce high quality and large quantity products.

Похожие товары

OEM изготовленный на заказ нестандартное стальное зубчатое кольцо путем литья с механической обработкой

Литье по индивидуальному заказу 304 из нержавеющей стали 4-1/5-1/6-1 автомобильный коллектор с турбо-коллектором

Высококачественный металлический сплав цинковый магниевый алюминиевый литой под давлением алюминиевые детали

Профессиональная обработка с ЧПУ алюминиевых изделий литье под давлением из магниевого сплава

Профессиональная обработка с ЧПУ алюминиевых изделий литье под давлением из магниевого сплава

Отливка отливки из магниевого сплава

Литейный завод OEM Подгонянная Шестерня из сплава стали отливки песка

Новые поступления

Новинки товаров от производителей по оптовым ценам