Корундовые огнеупорные кирпичи mullite используемые высокочистый плавленый корунд в качестве

- Категория: >>>

- Поставщик: Henan Lite Refractory Material Co. Ltd.

Сохранить в закладки 60718385737:

Описание и отзывы

Характеристики

Mullite Brick

1.Made from high-grade and high purity fused mullite or sintered mullite,being high pressure pressed and sintered in high temperature

2.Main minerals are mullite stone.

3.During the process of production,organic and multiple filling materials are injected accoridng to the required proportion.

Technique Data

Item | 75Mullite Brick | 70 Mullite Brick | Mullite-corundum Brick |

Al2O3 % | ≥75 | ≥70 | ≥80 |

SiO2 % | ≤23 | ≤25 | ≤18 |

Fe2O3 % | ≤0.4 | ≤0.4 | ≤0.3 |

Bulk Density g/cm3 | ≥2.7 | ≥2.6 | ≥2.8 |

Apparent porosity % | ≤18 | ≤18 | ≤18 |

Cold compressive strength MPa | ≥100 | ≥100 | ≥100 |

(0.2Mpa,0.6%)Load softening began to temperature °C | ≥1680 | ≥1680 | ≥1700 |

Feature

1.High temperature resistance

2.High strength,high compression resistance,

3.Excellent thermal shock resistance,

4.High bulk density, good thermal conductivity,

5.Good wear resistance and acid alkali corrosion resistance.

Shapes &Sizes

Straight | Split | Arch | Wedge | Tile | Tile | |||||

L×W×H(mm) 230×114×65 230×114×75 | L×W×H (mm) 230×114×25 230×114×32 230×114×37 230×114×50 | L×W×H/h(mm) 230×114×65/45 230×114×65/55 230×114×75/45 230×114×75/55 230×114×75/65 | L×W×H/h (mm) 230×114×65/45 230×114×65/55 220×114×75/45 220×114×75/55 220×114×75/65 | L×W×H (mm) 230×230×38 230×230×50 230×230×65 230×230×75 | Key brick, Skew brick, Soap, Checker, Neck, Taper, | |||||

We also can make brick according to customers’ drawing and requirements. | ||||||||||

Application

Primarily used for the key parts of the furnace of glass furnace,alkali-free glass fiber furnace,blast furnace hot blast stove,refractory–material tunnel kiln,the cracking furnace,conversion furnace, heating equipment,refining equipment,reproduction equipment,hot blast stove,heating furnace, tunnel kiln,shuttle kiln,glass-pool kiln etc

Packaging Details

1. Carton packaging .

2. tray + plastic film + fixed band .

3. pallets: 1*1m,0.93*0.93m .

4. tray weight: 1.6~2.0ton.

5. packaging according to customer service requirements .

Castable

Chrome-corundum brick

Mullite brick

Magnesia-chrome brick

Magnesia-carbon brick

High alumina bubble brick

Henan Lite Refractory Material Co., Ltd

is located in Zhengzhou Henan province,which is one of the main refractory production bases in China. Pengfei Zhang the manager of our company,has been engaged in refractory material industry for more than 15 years. In the technological team there are more than 10 senior designers and engineers,more than 20 technicians.

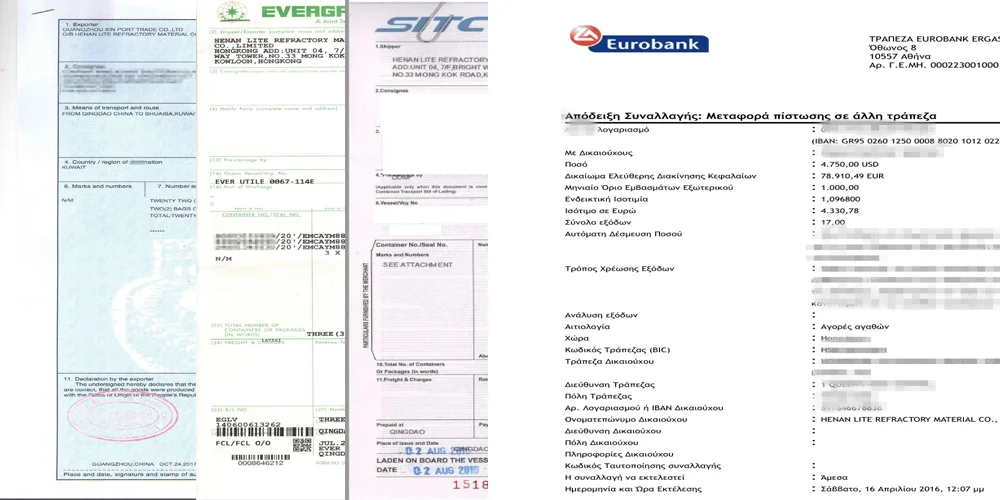

Customer Visit

Order

Lite Refractory is well known in domestic market and abroad for the variety and quality of the products.Products have been sold to Amercia,Greece,Malaysia,Vietnam,Russia,Korea,

Japan,South Africa,ect.

Q1.Can we visit your company?

A:Sure,welcome at any time,seeing is believing.

Q2. Do you provide samples?

A:Yes, samples are available.

Q3. Do you accept OEM?

A:Yes, we can do OEM.

Q4.What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q5.What are the payment terms?

A:Usually T/T,but L/C,Western Union etc are available for us.

Q6. How long is delivery time?

A:The delivery time will be determined according to the quantity of the order.

Q7.How are your products’ quality?

A:The products will be strictly inspected before shipment, so the quality could be guaranteed.

Q8.How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9.What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q10.How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

+86 037155178866

julia @literefractory.com

Whats/Skype:+86 18103864105

(950206liu)

Похожие товары

Высококачественная лучшая куртка-бомбер, шелковая атласная Мужская куртка, куртка-бомбер, оптовая цена от Mixfit Apparel

Оборудование для производства труб ERW

Высококачественный Синтетический Рубин драгоценный камень сырье шероховатый корунд материал 5

Большие роскошные вазы для домашнего декора, декоративные скандинавские вазы нового дизайна

Ручная работа, вязание крючком, милый кролик, свинья, Детская кукла для девочек, амигуруми, зайчик, Спящая игрушка, детские вязаные игрушки

Оптовая продажа натуральный красный корунд кристалл Рубина

Овальный корунд 3*5/4*6/5*7/6*8 мм для изготовления ювелирных изделий импортное французское

Новые поступления

Новинки товаров от производителей по оптовым ценам