Горячая Распродажа индивидуальная Пластиковая форма для водопроводного крана

- Категория: >>>

- Поставщик: Taizhou Kaiji Plastic Mould Co. Ltd.Taizhou Ltd.

Сохранить в закладки 60730682575:

Описание и отзывы

Характеристики

Specifications of plastic injection mould

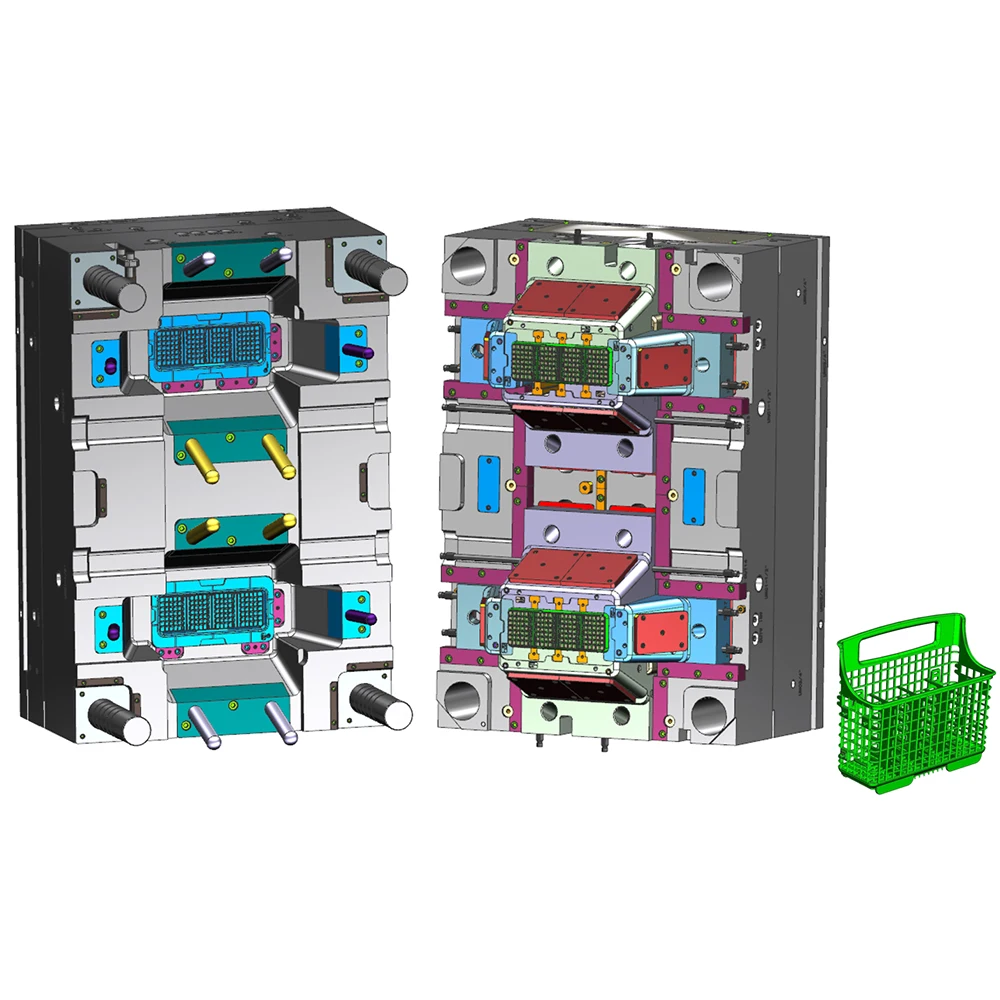

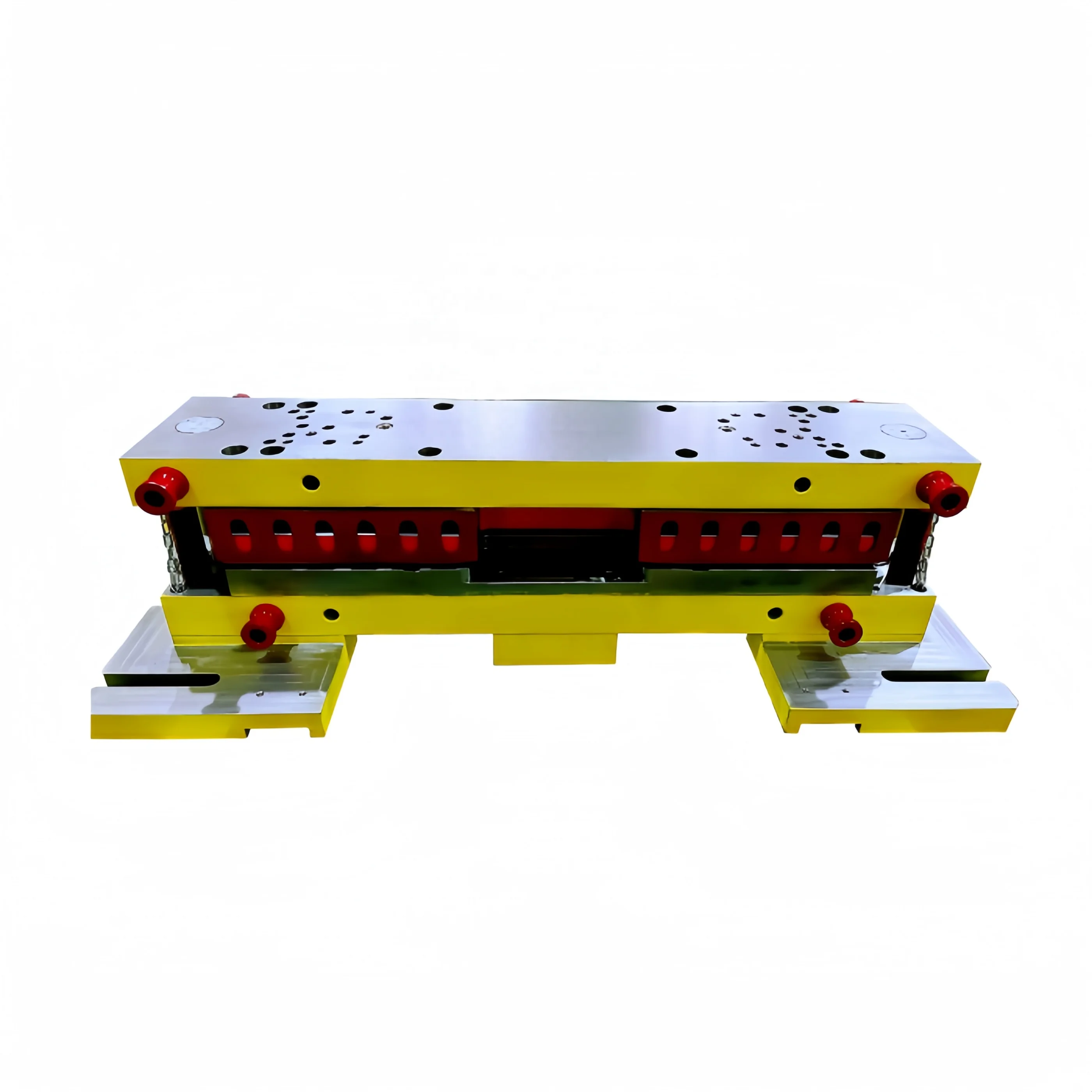

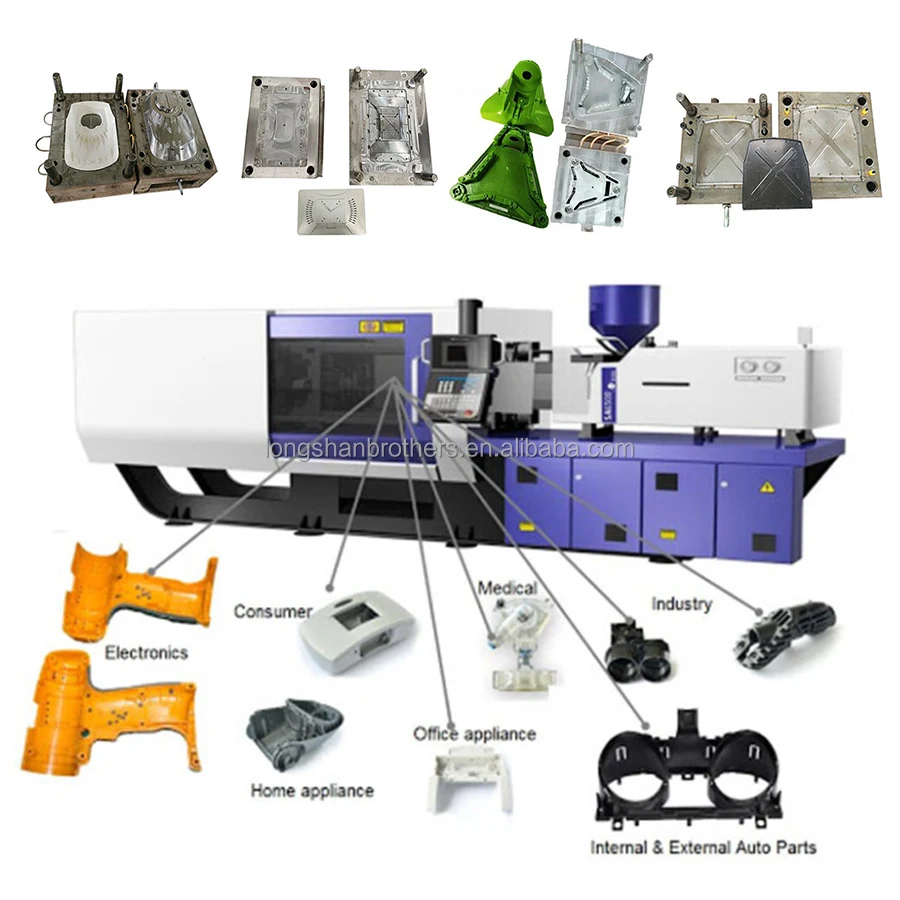

| Name | plastic water tap injection mould |

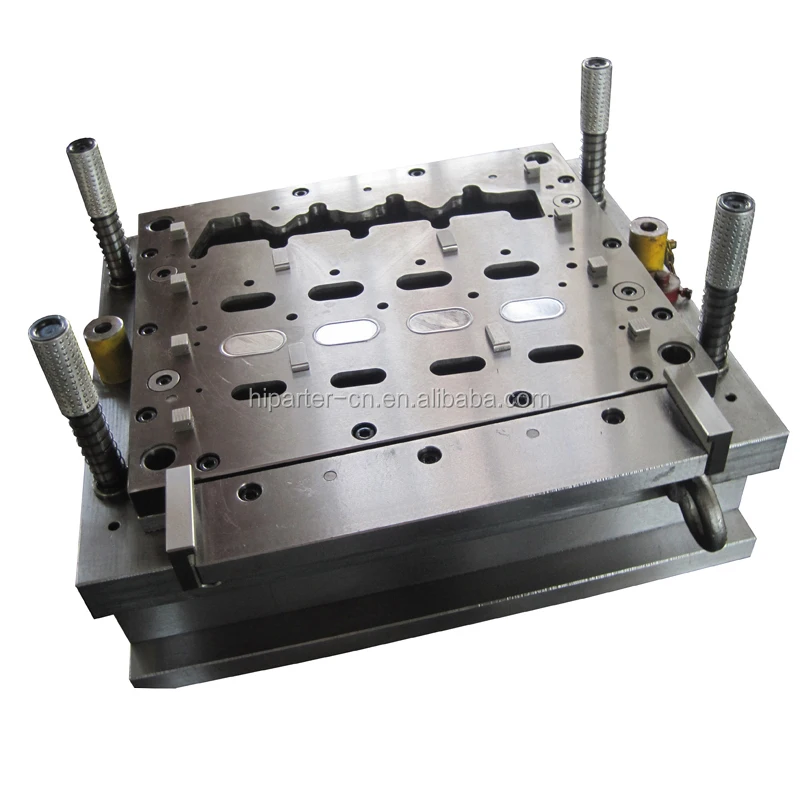

| Mould material | 2316, S136 |

| Mould base | LKM, HASCO,Kaiji standard |

| Cavity | Single/multi |

| Runner system | Hot/cold |

| Design software | NX_UG CAD, CAM, CAE |

| Plastic material | pp |

| Mould life | 500, 000-1, 000, 000 shots |

| Delivery time | 30-60 days |

| Packing | Wooden case |

Mould maintenance

a)When the mould is vacant, spray the anti-rust oil

b)To clean the gate and cooling system regularly

c)Avoid to use recycled material if the mould is suitable for virgin material only

Mould quality control

For the Q/C of mold, there are 3 steps:

1.Mould Material Q/C

- Mould Steel Checking(Hardness, flaw detection)

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

2.Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- Each part of mould’s size checking after machining according to 2D drawing

- mould testing(check mould running condition)

3.check with customer’s requirement again before mold shipping.

Primary Competitive Advantages:

1. Approved Quality

2. On-Time Delivery

3. Reasonable Price

4. Experienced Staffs

5. Reliable Post-Service

6. Good Reputation

Service

a)Engineering and one interpreter can be sent to customer’s factory for first running.

b)one-year after-sale technique support

c) We will supply process pictures of the mould once a week.

Contact information:

Contact person: Michelle

Mobile phone(Whats app/ Wechat/Skype): 008613757667664

Email:sasha(at)chinakaiji.com

Похожие товары

Металлические штампованные штампы ручные инструменты для штамповки пресс-формы автомобильного штампа прогрессивные детали

Высококачественная пластиковая литьевая форма для игрушек изготовитель пресс-форм детских товаров

Пластиковые литьевые детали под заказ силиконовые формы для бытовой техники горячие и холодные направляющие

Горячая распродажа изготовленная на заказ пружина из сплава пресс-форма для штамповки компрессионная металлическая высокого качества

Циндао OEM ISO9001 Автомобильная прокладка из листового металла четыре или шесть прокладок прогрессивный штамп

ПВХ асфальтоукладчик блокирующие бетонные пластиковые формы для асфальтоукладчиков

Пластиковая вставка для литья под давлением оборудования TCF

Новые поступления

Новинки товаров от производителей по оптовым ценам