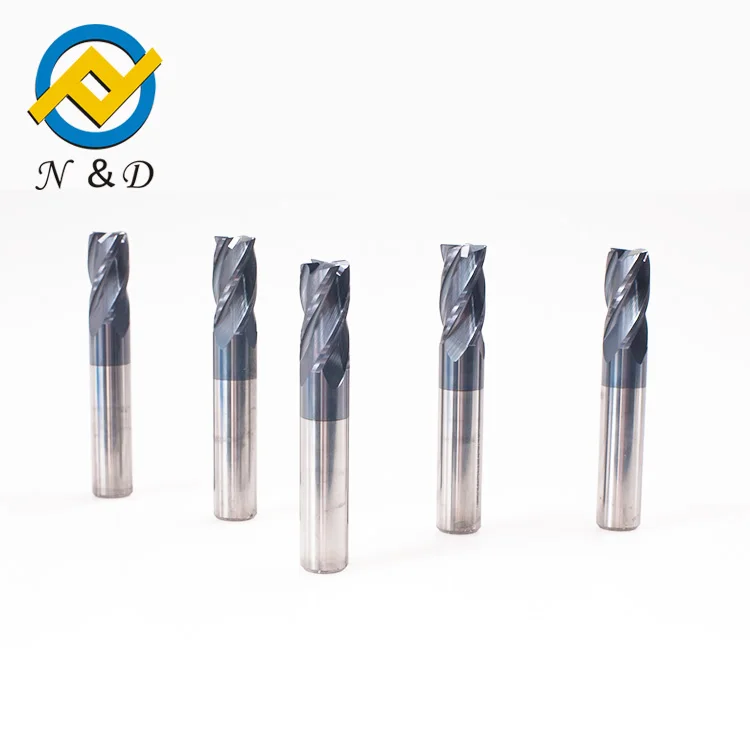

Прямая Продажа с завода твердосплавные торцевые фрезы ЧПУ высокопроизводительные режущие инструменты

- Категория: >>>

- Поставщик: Guanghan N&D Carbide Co. Ltd.Guanghan Ltd.

Сохранить в закладки 60730691768:

Описание и отзывы

Характеристики

Factory Direct Sale Solid Carbide CNC End Mill High Performance Cutting Tools

Grade | ISO | Composition(%) | Hardness | Density | T.R.S | ||||

WC | Co | Ni | TaC | others | |||||

LG05 | K05-K10 | 94 | 6 | - | micro- | - | 91.0-92.5 | 14.9 | 1600-2200 |

LG105 | K10 | 94 | 6 | - | - | - | 90.0-92.0 | 14.9 | 2400-2800 |

LG10 | K30 | 92 | 8 | - | - | - | 89.0-91.0 | 14.6 | 1850-2400 |

LG20 | K20 | 90 | 10 | - | micro- | - | 91.5-92.0 | 14.4 | 3500-4000 |

LG120 | K40 | 90 | 10 | - | micro- | - | 86.5-88.0 | 14.3 | 2600-3500 |

LG30 | K50 | 88 | 13 |

| micro- |

| 88.0-89.5 | 14.2 | 2400-2600 |

LG40 | G-30 | 85 | 15 |

|

|

| 86.0-87.0 | 13.9 | 2800-3300 |

LYN101 | - | 94 | - | 6 | - | 0.5 | 89.0-90.0 | 14.8 | 1500-1700 |

LYN102 | - | 92 | - | 8 | - | 0.5 | 88.0-89.0 | 14.6 | 1700-1900 |

LYN103 | - | 90 | - | 10 | - | 0.3 | 87.0-88.0 | 14.5 | 2000-2200 |

LYN104 |

| 88 |

| 12 |

|

| 88.5-90.5 | 14.3 | 2500-2650 |

LYN105 | - | 60 |

| 12-15 |

| 28-30 | 89.0-90.5 | 9.0 | 2400-2600 |

L016 | - | 74 |

| 15.5-16.2 |

| Ti:8.5-9.5 | 88.0-88.5 | 12.0 | 1500-1800 |

A20 |

| 89.5-90.5 |

| 9.5-10.5 |

| Ti:3-4 | 88.0-89.0 | 13.5 | 1500-1600 |

A30 |

| 90.5-91.5 |

| 8.5-9.5 |

| Ti:0.5-0.8 | 88.0-89.0 | 14.5 | 1600-1700 |

Solid carbide end mills with standard geometry, which makes it capable of cutting a wide range of materials.

Advantages:

1. Made of 100% carbide raw material.

2. Non-standard can be customized according to customer's requirements.

3. All products go through in processes and final inspections strictly.

4. Guarantee stable quality and performance.

5. We have more than 10 years' experience in this field.

Nickel Binder Grades:

Grade | Binder (wt%) | Density (g/cm³) | Hardness (HRS) | TRS (≥N/mm2) |

YN6 | 6 | 14.7 | 89.5 | 1460 |

YN6X | 6 | 14.8 | 90.5 | 1400 |

YN6A | 6 | 14.8 | 91.0 | 1480 |

YN8 | 8 | 14.6 | 88.5 | 1710 |

Cobalt Binder Grades:

Grade | Binder (wt%) | Density (g/cm³) | Hardness (RS) | TRS (≥N/mm2) |

YG6 | 6 | 14.8 | 90 | 1520 |

YG6X | 6 | 14.9 | 91 | 1450 |

YG6A | 6 | 14.9 | 92 | 1540 |

YG8 | 8 | 14.7 | 89.5 | 1750 |

YG12 | 12 | 14.2 | 88 | 1810 |

YG15 | 15 | 14.0 | 87 | 2050 |

YG20 | 20 | 13.5 | 85.5 | 2450 |

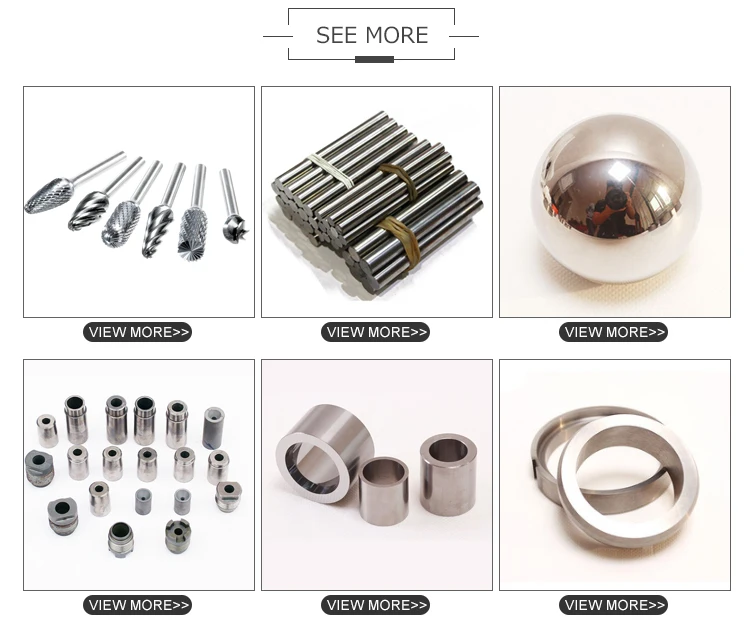

Founded in 2004, Guanghan N&D Carbide Co Ltd is one of the fast growing and leading manufacturers in China working specifically with super hard metals. We specialize in producing a wide range of wear part for oil & gas drilling, flow control and cutting industry.

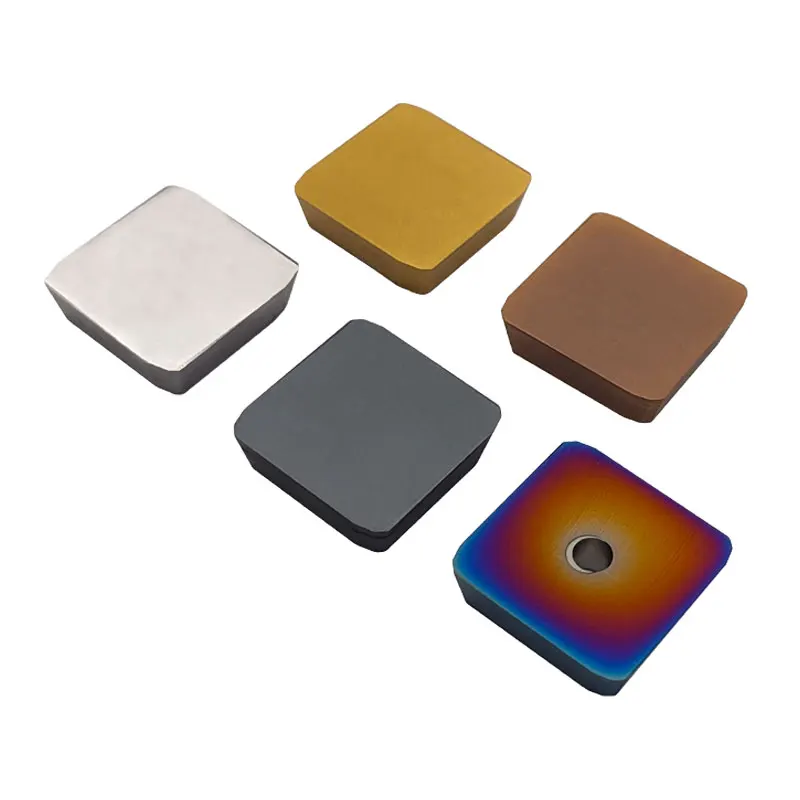

From the selection of premium raw materials to the precision finishing and polishing of complex parts,ND performs all process steps. ND Carbide also offers a full range of carbide grades in both cobalt and nickel binders. These include micro grain grades for applications requiring exceptional combinations of wear resistance and tensile strength, hardness for use in highly corrosive environments, and high cobalt binder grades for production tooling applications demanding high toughness and impact strength.

ND Carbide produces all of the carbide covered by the industry standards as well as custom grades to meet special customer requirements. The cemented carbide material are available either as semi-finished blanks or as precision-machined parts.

We are looking forward to have a good cooperation with your esteemed organization!

Похожие товары

Горячие продажи OEM твердосплавные инструменты по последней цене производители и поставщик лучшей

1*4*50 Карбид 50 градусов фрезерный резец фрезерные инструменты резак Cnc Фрезерный

65 градусов стандартная 4-гранная Концевая фреза из карбида вольфрама для обработки с ЧПУ

Прямые продажи с завода твердосплавные станки ЧПУ фрезы для обработки стальных деталей из нержавеющей стали чугунная закалочная сталь

Прецизионные характеристики: 90-градусные карбидные фрезы для алюминия высокой точности долговечности и универсальности

Китай поставщик карбидный плоский резак 60 hrc 55 45

Набор инструментов с ЧПУ 35 спиральных твердосплавных концевых фреза производитель фрезерных станков

Новые поступления

Новинки товаров от производителей по оптовым ценам