Золотодобывающий гравитационный сепаратор оборудование 6s Вибрационный стол для продажи

- Категория: >>>

- Поставщик: Jiangxi Well-Tech International Mining Equipment Co. Ltd.

Сохранить в закладки 60731827528:

Описание и отзывы

Характеристики

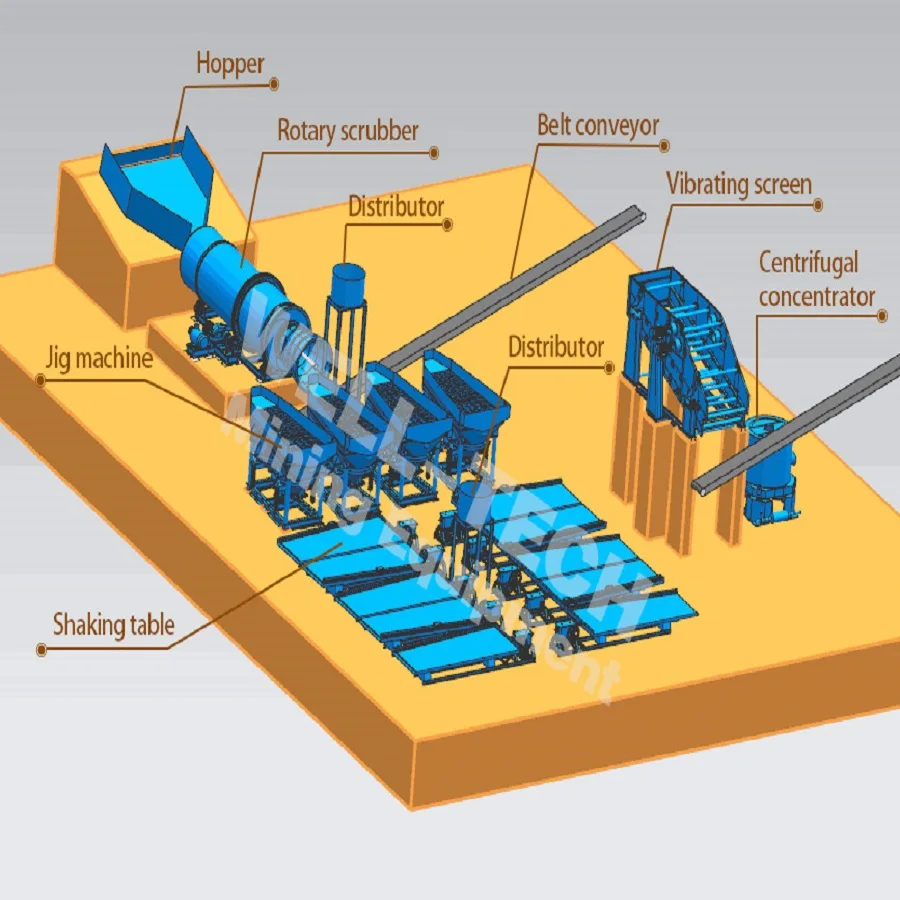

Product Application

6-S Shaking table which is also called table concentrator, is a mine separation device for fine minerals working by

gravity. They are effective in processing precious and base metal, rare metal and non-metallic minerals, widely

used in separation for Gold, Silver,Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome,

Manganese, Zircon, Lead, Zinc, Mercury, Copper, Aluminum, etc.

Separating precisely is the prominent advantage of shaking table. We can get some final concentrate, final tailings

and 1 or 2 kinds of middling product after the first separating from raw mineral. The enrichment ratio of concentrate

is very good, when dealing with low grade tungsten ore and tin ore, the enrichment ratio could reach about 300

times. Besides, the range of separating particle size effectively in dealing with metallic ore is 3 to 0.02 mm.

SPECIFICATIONS FOR 6-S SHAKING TABLE | ||||||||

Model | 6-S 7.6 | 6-S 4.08 | 6-S 1.95 | 6-S 0.5 | ||||

Beneficiation area (m2) | 7.6 | 4.08 | 1.95 | 0.5 | ||||

Maximum feeding size (mm) | 2-0.074 | Sand -2 Slime -0.1 | Sand -2 Slime -0.074 | Sand -2 Slime -0.074 | ||||

Capacity (t/h) | 0.3-1.8 | 0.4-1.5 | 0.3-0.8 | 0.05-0.2 | ||||

Feeding density (%) | 15-30 | 10-30 | 10-30 | 10-30 | ||||

Stroke (mm) | 8-22 | 6-30 | 12-28 | 9-17 | ||||

Frequency of stroke (r/min) | 220-280 | 210-320 | 250-450 | 280-460 | ||||

Water consumption (t/h) | 0.4-1 | 0.3-1.5 | 0.2-1 | 0.1-0.5 | ||||

Power (Kw) | 1.1 | 1.1 | 1.1 | 0.55 | ||||

Dimension(mm) | 5600x1850x860 | 4075x1320x780 | 3040x1050x1020 | 1530x500x800 | ||||

Weight(Kg) | 750 | 550 | 350 | 150 | ||||

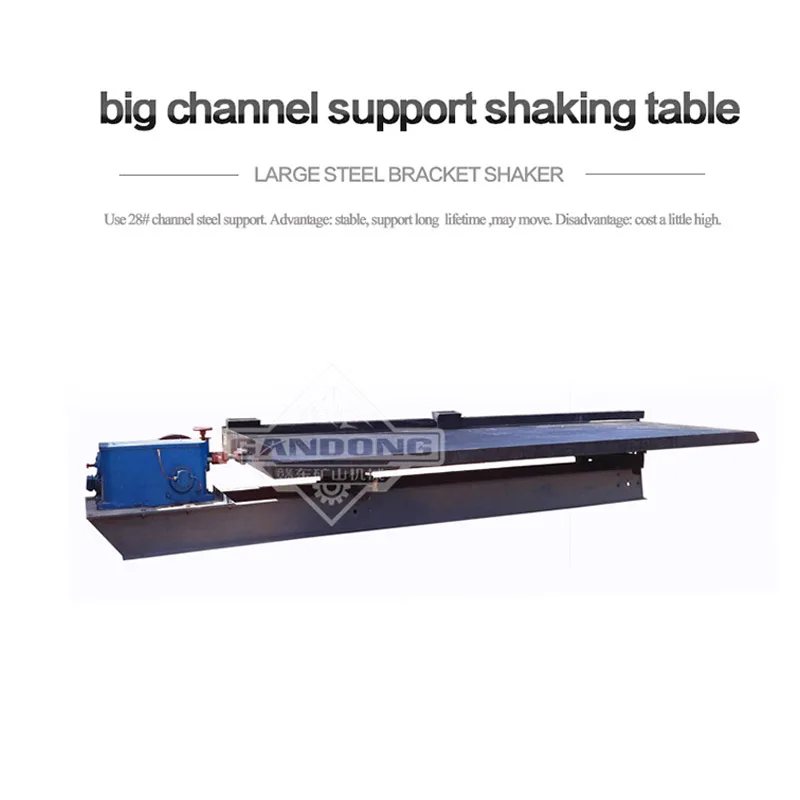

6-S7.6Shaking table with 10#channel steel support. 6-S7.6Shaking table with 28#channel steel support

Main Features

1.High recovery ratio;

2.High concentration ratio;

3.Easy installation;

4.Simple operation;

5.Deck constructed of fiber glass;

6.Seven different decks to choose;

7.Long working life;

8.Adjustable stroke length and speed.

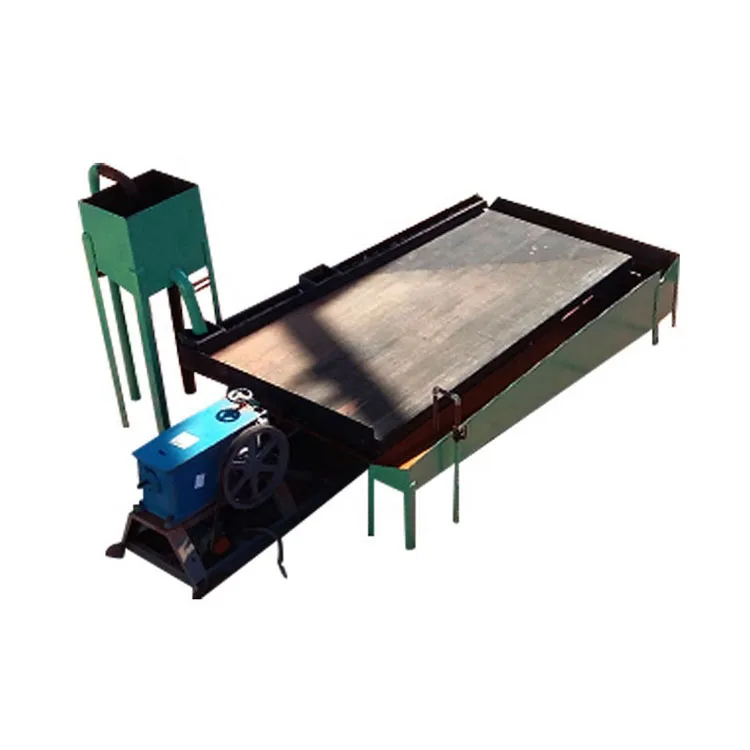

Working principle

The working principle of Shaking Table is to use the combined action of the specific gravity difference of sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove),

to allow loose layering of ores on the bed surface and fan-shaped zoning. Then different products can be produced.

Machine Parts

Name: Drive engine

Brand: GANDONG

Main Parts

Name: Fiberglass Deck

Brand: GANDONG

Fibergrass deck surface,manganese steeel fram

Working on site

2 layer deck shaking table

2 deck ,save space ,increase capacity.

4 layer deck shaking table

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

FAQ:

Q: What Information should customers give to us?

1) If rock ore, max feeding size? Capacity?

2) If alluvial/placer ore,contain sticky clay ore? If yes, more than 30% or not? and -5mm materials percentage? Capacity?

2) Mineral elements and content?

Q: Can we send the mineral samples to your company, let your company run the ore-dressing experiments test for us?

A: Yes, we have a laboratory equipped with complete mining equipment which including jaw crusher, hammer mill, ball mill, jig

machine, gold centrifugal concentrator, spiral chute, slurry pump, mixing tank, shaking table, dry magnetic separator, wet

magnetic separator, three disc magnetic separator, electricity separator etc. So we can run the ore-dressing experiments for our

customers. After the test, we will based on the results to give you the reasonable flowchart, suitable solution and equipments

selection. etc.

Q: How long is the guarantee of your equipments? Does your company supply the spare parts?

A: The warranty period of is one year, if break during this guarantee period, we need to free replace new one for you . And of

course we will supply the spare parts for you for life-long time at lowest cost.

Q: If i need the complete mineral processing line. Can you help us build it?

A: Yes, we can help you combine a complete mineral processing line. and give you related professional advices as long as you need.

There is a rich experienced engineers team of us, we can provide design flowsheet,manufaturing machine, installation, debugging

our equipments on your worksite and trainning the buyer's staff.

Loading | ||

Container | 40HQ/40GP/20GP | |

Load Port | Xiamen , Shenzhen,Shanghai | |

Trade term | FOB,EXW,CIF,CFR | |

Delivery time | Within 35 days after recieve 30% deposit,balance before loading | |

Centrifugal concentrator

91.8% Response Rate

Jig concentrator

91.8% Response Rate

Spiral concentrator

91.8% Response Rate

18379873189,Thanks for your time!

Похожие товары

Рождественская кружка, креативная 3D модель животного, кофейная чашка, чашка для завтрака, молока, праздничная подарочная чашка

Профессиональный производитель, карабин Bungee, быстросъемная вращающаяся Пряжка, гамаки, поворотный карабин для скалолазания

Производитель хлопок хип-хоп обычный флисовый пуловер оптовая продажа с длинными рукавами на заказ Мужская пустая крупногабаритная Базовая Спортивная

1 кг в упаковке полимерная глина Hengxin смесь цветов форме сердца для слайма дизайна ногтей поделок на День святого

Купить Качественный молочный порошок nestle nido оптом

Высокое качество популярный наш собственный производитель разъем питания постоянного тока компьютер для

Стекловолокно морская Удочка Супер жесткий с 5 слоев ткани прямые поставки с завода, оптовая продажа

Новые поступления

Новинки товаров от производителей по оптовым ценам