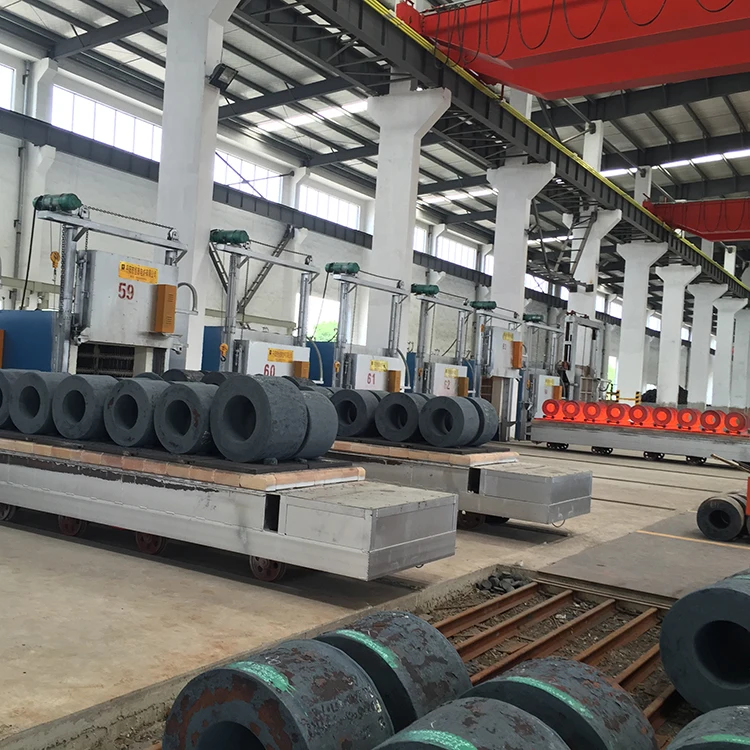

Самая дешевая высокопроизводительная печь для ковки металла типа тележки

- Категория: >>>

- Поставщик: Jiangsu Weier Furnace Industry Co. Ltd.

Сохранить в закладки 60732996475:

Описание и отзывы

Характеристики

Heat treatment equipment provides annealing, tempering, quenching, carburizing, nitriding, heating to the workpieces.

Heat treatment furnace is common name of various kinds of industrial furnace which provide metal heating treatment to all kinds of metal workpieces. It has lower temperature compared with heating furnace. Heat treatment furnace can be adopted with all models of heating furnaces but asks more stringent temperature control and furnace atmosphere.

Heat treatment furnace is divided into annealing furnace, quenching furnace, tempering furnace, normalizing furnace, quenching and tempering furnace, carburizing furnace, nitriding furnace, melting furnace. Mainly used for high chromium, high manganese steel castings, ductile iron, roll, steel, stainless steel quenching, annealing, aging and a variety of mechanical parts heat treatment. Welding parts to eliminate stress annealing, aging and other heat treatment process. Heating methods are electric heating, fuel, gas, coal, hot air circulation and etc.

1. Various of combustion gases as the medium, heating through the various types of burner combustion, the maximum temperature up to 1200 ℃.

2. Furnace frame welded by a variety of large and medium-sized shaped steep in the site. Shell is color steel plate. High-alumina full fiber refractory silk blanket module for the lining. Sealing and energy-saving effect is obvious.

3. Car frame welded by a variety of large I-beam steel, channel steel, angle steel and thick steel plate and other combinations.

4. The drive is reliable. The transmission system adopts motor - reducer. The installation method is shaft-mounted. Compact structure, strong assembly, flexible access, simple operation and convenient maintenance.

5. Car refractory masonry with high aluminum stereotypes brick structure, the sealing effect is good, high compressive strength. The car sets the iron plate for the stacking of the workpiece. The sealing of car and lining with automatic compression structure. Open and close of the side seal connects with the furnace in & out system.

6. The door is made of high-alumina full fiber refractory silk blanket and steel frame structure. Electric hoist lift. Door sealing mechanism with long levers spring-type automatic compression cam mechanism and soft side seal device. That ensures no friction from top to bottom, easy, safe and reliable.

7. Chimney installed automatic pressure control device and butterfly valve, etc., can adjust the cooling rate.

8. Heating with high-speed burner, evenly distributed on both sides. The actuator adjusts the air flow, adjusts the amount of gas by the proportional valve, there is lower limit of the gas and the air flow, the control tube is equipped on the gas pipe of each burner, and each burner is equipped with independent and complete combustion Controller which with automatic ignition, flame detection, fire alarm and automatically cut off gas features.

PS:Our company can provide customized design according to user requirements.

Applicable to all kinds of mechanical parts need gas carburizing, carbonitriding and normalizing, annealing, tempering treatment.

²The furnace is nude packed but duly fixed inside the container.

²The nearest sea port is Shanghai port which is the largest and most convenient port over China.

²The delivery time is 45-120 days after receipt of down payment.

²The furnace is usually loaded into normal containers (20GP or 40GP) or flat racks.

²Usually machine is packed with wooden case and standard export carton, plywood carton or as your requirement.

l Reply your inquiry within 48 working hours

l Experienced engineer instruct and sales communicate with you in fluent English.

l Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

l More contact with users, communicate with each other, to ensure that the manufacturing products meet the needs of customers.

l Production: strict quality standard, to produce machine and induction coils.

l Installation on site and commissioning in the condition of cold and hot, to ensure the normal use.

l Tracking goods shipping and provide bill of lading,invoice,packing list and other documents what you need

l Provide install and technology instruction by sending drawings, email, or telephone,video.

l If you need, will arrange one engineer to your place,instruct install machine and training operators.

l Responsible for free training of technology, service and operation personnel's theory, maintenance and operation skills, to make users use production right and expertly. Training is in the section of device debugging and test run.

l After equipment final acceptance, quality guarantee period is for 12 months, the supplier replace and repair for free when the damage is caused by production and materials during the warranty period. To the damage out of warranty period, the supplier should give preferential service and the supply of parts (only accept costs), and provide lifelong offer after-sale service.

Our factory has more than 30 years experience of research and development in heat treatment equipment. We have introduced of ISO international quality management system, and cooperate with the Chinese Academy of Sciences and Tsinghua University. We have established industrial furnace design center. Winning the 7.5 million Indonesian steel continuous annealing tempering production line heat treatment equipment projects.We have the patents of bell type ball annealing furnace, low temperature pit furnace, large pit furnace, ring pit type heat treatment furnace, car type resistance annealing furnace, energy saving carbon fiber baking furnace, aluminum alloy cable heat treatment furnace, recycling efficient quenching and tempering equipment, the atmosphere protective cover movable station furnace, variable capacitance of car type resistance furnace. At the same time, having undertaken the design and manufacture of heat treatment equipment nearly ten thousand sets, our products exported to Germany, Thailand, North Korea, Pakistan, Vietnam, Malaysia, Indonesia, Singapore, Nigeria, more than 10 countries, and have customers all over the world. We provide customers with a wide range of advisory services. According to product material, size, quality standards, and yield, the corresponding heat treatment process and furnace is made.

1. What’s your MOQ?

At present we haven’t strict policy for this, so welcome orders with any quantity.

2.What information should the our provide to get an accurate quotation from you?

The customer should provide the working temperature, temperature rising speed, energy medium (gas or electricity), effective size of the furnace, drawings, pictures, industrial voltage, etc.

3.You are a green hand on Alibaba, how can I trust your company and machine?

Our factory have been in Heat treatment equipment for around 20 years , just entering alibaba for ads .And our machine have exported to East Asia, South Asia, the middle East Asia, Africa etc. areas and have a good feedback with no complaints.

4.If there are broken of your machine and spare parts , what should I do ?

In case of any failure occurred in the warranty, damaged parts to be replaced shall be offered free of charge .we providelifelong tracing service, supply equipment parts and relevant maintenance at favorable prices, and give user technical guidance free of charge.

Похожие товары

Android Tesla вертикальный экран 13 'Автомобильный GPS Видео аудио радио плеер для Toyota Alphard 2015-2019 Wifi store

Точечная Поставка тяжелых круглых миниатюрных линейных направляющих Qeh15ca, направляющая, линейное движение

С рисунком Микки и Минни брелок портмоне силиконовые мини-сумка для наушников для влюбленных с милым рисунком из мультфильма «Город героев»; Модные Брелок Кошелек для монет

AB0001601 SF- 1008 платформа лодка Расширенный корпус каноэ каяк гладкая ручная гребля дешевые каяки рыболовные одноместные каяки

Свадебная бумажная музыкальная шкатулка высокого качества на заказ, музыкальная шкатулка балерины

Оригинальный THK линейный движение HSR25A линейный направляющий блок HSR25A1UU

Honeypuff Creative Disguise Lipstick 72mm Aluminum Weed Smoking Pipe Tobacco Detachable Long Weed Pipe Smoking Accessories

Новые поступления

Новинки товаров от производителей по оптовым ценам