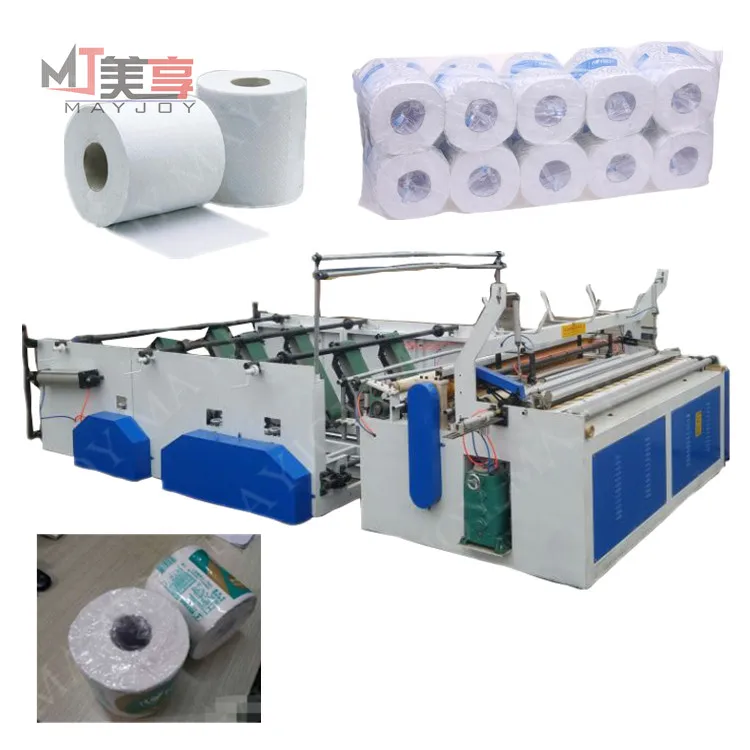

Прямая поставка с завода машина для производства рулонов туалетной бумаги продажи в Гане

- Категория: >>>

- Поставщик: Zhengzhou Mayjoy Import & Export Co. Ltd.

Сохранить в закладки 60739534574:

Описание и отзывы

Характеристики

Factory Direct Supply Toilet Paper Roll Making Machine for Sale in Ghana

Brief Description of Toilet paper roll making machine

The toilet paper roll making machine is used for processing the material bobbin by embossing ,folding,electric

counting,cutting into square napkin,automatic embossing folding no need manual folding ,

the embossing type can made by customer’s need to made different Clear and beatiful Pattern.

Technical Specification of Toilet paper roll making machine

Name | Toilet paper roll making machine |

Model | MJY-1760 |

Original paper width | 2000mm |

Capacity | 2T/day |

Original paper external diameter | 1100mm(can be changed) |

Finished product dia | Adjustable |

Program controller | PLC computer Program |

Produce speed | 0-280meter/min |

Embossing parts | Steel roller,wool roller,Rubber rollers |

Embossing situation | No Embossing ,single Embossing,double Embossing |

Optional Function | Automatic core dropping |

Machine conveyor | Continuously variable transmission. |

Paper remove shelf | 1-4 layers |

Brake | Electric,pneumatic control |

Main power | 5.5kw+0.75kw |

Dimension | 6500*3200*1900mm |

Total weight | 2300kg |

Features of Toilet paper roll making machine

1. This model is designed with PLC control system, fully automatic in production process, the function is complete and the production speed is high. The finished rewinding process implements tight first and loose later and different stage loose degree, resolve paper and core apart in the long storage time.

2. It can automatically change the core, spray the glue and seals without stopping the machine and also automatically raise and lower speed when exchanging the core.

3. When change the core, the machine will be tight first and loosen later to avoid dropping off the roll core.

4. Equipped with automatic alarm to indicate filling up of core pipe. The machine will be automatically stopped when there is no core pipes. Automatic alarm for breaking off of paper.

5. Equipped separate tension control for each unwinding jumbo roll.

6. It is convenient to change the feature to produce any other core pipe winding.

7. Left paper remind after sealing of product for convenient use.

8. Jumbo roll stand is installed by pneumatic.

9. Stepless adjustment , every function can independent operation.

10. Three-layer horizontal paper remove shelf, pneumatic type wide belt for paperfeeder, each group of original paper shelf has independent tension adjustment device ; point-to-point embossing, pattern is distinct and beautiful, light weight, can be configured according to the user's needs for steel to steel embossing ;inching switch for the traction of the original paper, the operation is simple, safe and practical.

Toilet Paper Machine Buyers’ Guide:

1.We have napkin paper machine,toilet paper machine,facial tissue paper machine and pocket tissue paper machine.etc. Firstly,what machine are you looking for ?

2.The one that you are checking is the toilet paper machine,there are various models for choice,1092,1575,1760 and 1880,etc. Which model do you want ? Among them,the model 1575 is the most popular to export abroad,and the 1880 Model is the most popular in China.

3.Usually to make the toilet paper machine,three machines are needed,it contains rewinding machine,cutting machine and sealing machine.This is basic three machines.

4.Do you make the toilet paper roll with inner core or without inner core ? If you will make toilet paper with inner core,the paper core making machine is optional.Of course you can buy finished paper core directly to use.

5.For the toilet paper rewinding machine,do you need embossing or not ? The basic function has no embossing function,if you need embossing,single embossing or double embossing ?

6.If you want embossing function,what embossing pattern do you want ? The embossing patterns can be designed as your request.Of course we also can supply some patterns designs for choice.

7.If you will make the toilet paper roll with inner core,do you need automatic paper core dropping function ? This is optional function.If no paper core dropping function,the machine also can do both toilet paper with inner core and without inner core.

8.The rewinding machine own functions include automatic rewinding,perforation,cutting,glue spraying,automatic pneumatic paper loading,and automatic synchronous belt. Other functions are optional.

9.Besides,we also have napkin paper machine,facial tissue paper machine,pocket tissue paper machine and jumbo roll paper rewinding cutting machine,etc.

FAQ:

1.What is the net profit of toilet paper and napkin paper?

For toilet paper, it is about 20%. That is, the profit is about USD100-USD140 for per ton.

For napkin tissue, it is about 30%. That is, the profit is about USD350 for each ton.

2.How can customers obtain the raw material?

The raw materials are mainly made from wood pulp, cane syrup, deinked waste paper.

You can purchase the raw material in your area. If you like, we can purchase raw material from our cooperated suppliers in China at low cost for you.

3.How many bags can we get from 1 ton of raw pulp material?

If 100g for one roll of paper, 10 rolls in a bag, we can get about 900 bags from 1 ton of raw material.

4.For our MJ-1570C toilet paper rewinding machine, what is the plant area?

The overall dimension of our machine is 6m(length)*3m(width)*1.8m(height), to take the working table into account, the plant area is about 50m2. The height of door is 2m. (The warehouse is not included. )

5.What is the investment for processing toilet paper?

About USD19,000. It includes the equipments(rewinding machine+slitting machine+sealing machine), workshop, raw material, etc.

Why choose us ?

1. We are a professional manufacturer to make toilet paper roll making machine for 26 years history.

2. We have a whole complete service, include researching, designing, manufacturing, selling and after-sale service. To keep the best products for all customers.

3. Our company located in Zhengzhou,Henan which is in North China,very closed to China seaport,it is more convenient to export.

4. 100% QC inspection and debugging before shipment.

5. 100% rest assured after-sales service.

If you need to learn more information about our machine and this field information,please feel free to contact me:

Похожие товары

H155 Высококачественная тонкая беспроводная сенсорная клавиатура для ТВ-приставки для ПК для ноутбука тонкая мультимедийная клавиатура с 78 клавишами с ножницами

Машина для производства бумажных пакетов с квадратным дном для кормления

Автоматическая машина для изготовления бумажных ручек, линия по производству ручек, машина для скручивания бумажных ручек

Клавиатура для ноутбука 320-15ABR 320-15IAP 320-15AST 320-15IKB 320-15ISK SP LA teclado

Клавиатура-наклейка WENJUN, 2 клавиши, поддержка переключения MX, программирование механической клавиатуры, макро-клавиатура

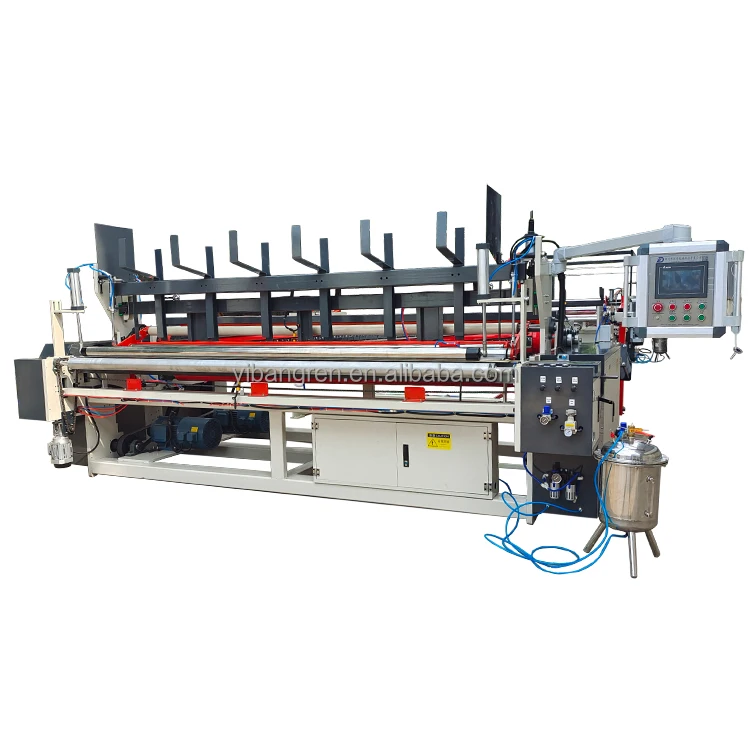

Yibangren, машина для резки и перемотки туалетной бумаги

Lc1 серии Lc1d38 Lrd реле 3-фазный 38a переменного магнитного контактора Магнитный стартер механический

Новые поступления

Новинки товаров от производителей по оптовым ценам