Китайская сушильная машина для абрикоса в Индии тепловой насос сушилка по хорошей цене

- Категория: >>>

- Поставщик: Henan Baixin Machinery Equipment Co. Ltd

Сохранить в закладки 60741570112:

Описание и отзывы

Характеристики

China Made drying machine for apricot at india heat pump drier with good price

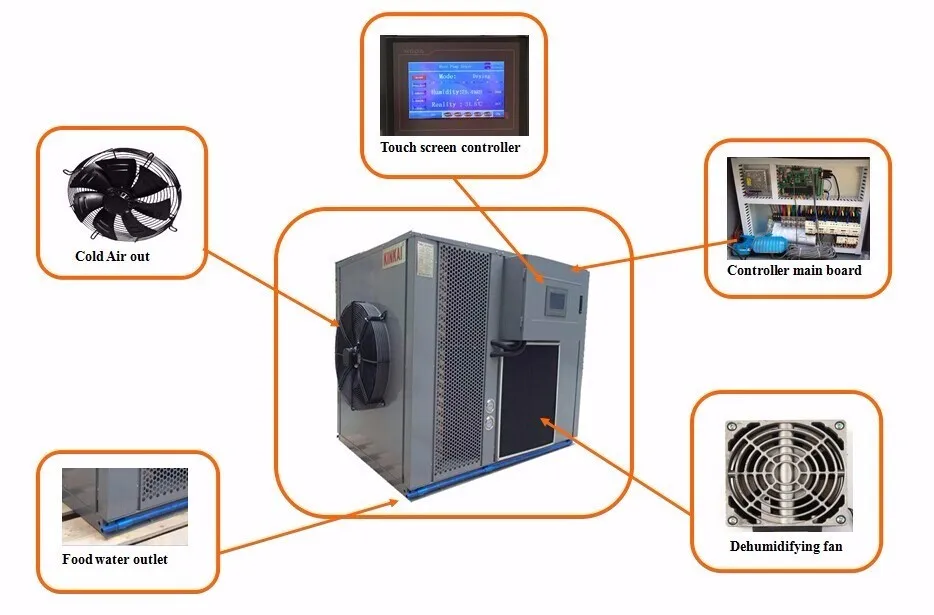

Commercial cabinet dryer industrial fruit meat beef jerky dehydrator

Industrial meat dehydrator according to a basic reverse Carnot cycle. The working fluid (refrigerant) at low pressure is vaporized in the evaporator by heat drawn from the dryer exhaust air. The compressor raises the enthalpy of the working fluid of the heat pump and discharges it as superheated vapor at high-pressure. Heat is removed from the working fluid and returned to the process air at the condenser. The working fluid is then throttled to the low-pressure line (using an expansion valve) and enters the evaporator to complete the cycle. In the dryer system, hot and dry air at the exit of condenser is allowed to pass through the drying chamber where it gains latent heat from the material. The humid air at dryer exit then passes through the evaporator where condensation of moisture occurs as the air goes below dew point temperature. Then drain the condenser water.

Working principle draft

Compressor

1.Copeland scroll compressor.

2. High efficiency.

3. Low noise.

4. Long lifetime.

5. Long working time design.

6. Two-days ccroll soft design.

Titanium heat exchanger

Electric expansion valve

1. Good degree of superheat well and smart.

2. Wide adjust range.

3. Refrigerant flow control accurate .

4. Evaporate temp is not affected by superheat degree.

4-Way valve

1. For defrost in winter.

2. For heating mode and cooling mode change.

Evaporator

1. Inside thread copper.

2. Hydrohilic aluminous foil.

3. Balanced liquid separator.

Fan

1. Low noise.

2. High air flow.

3. Anti-freezing.

4. Waterproof.

\t\t\t\t

Click here for more information

Похожие товары

Оптовая продажа, модный электрический скутер для взрослых с большим колесом мощностью 300 Вт

2020 новые вертикальные системы выращивания растений для гидропонных

Производство гидропонных столов для внутреннего

Work pants multi pockets for carpenter and painter and construction tools Industrial pants Safety Pants Worker trousers

Черная зеркальная фоторамка, акриловый Топпер для торта, украшение для свадебной вечеринки, романтический современный Топпер для торта, знак для вечеринки

Резиновый шланг для всасывания и разряда шлама с помощью нейлонового шнура 2-8 1 встроенной стальной спиральной

Гофрированные резиновые шланги/всасывающие и поставляемые шланги из нейлонового шнура 2-8 с 1 встраиваемой стальной

Новые поступления

Новинки товаров от производителей по оптовым ценам