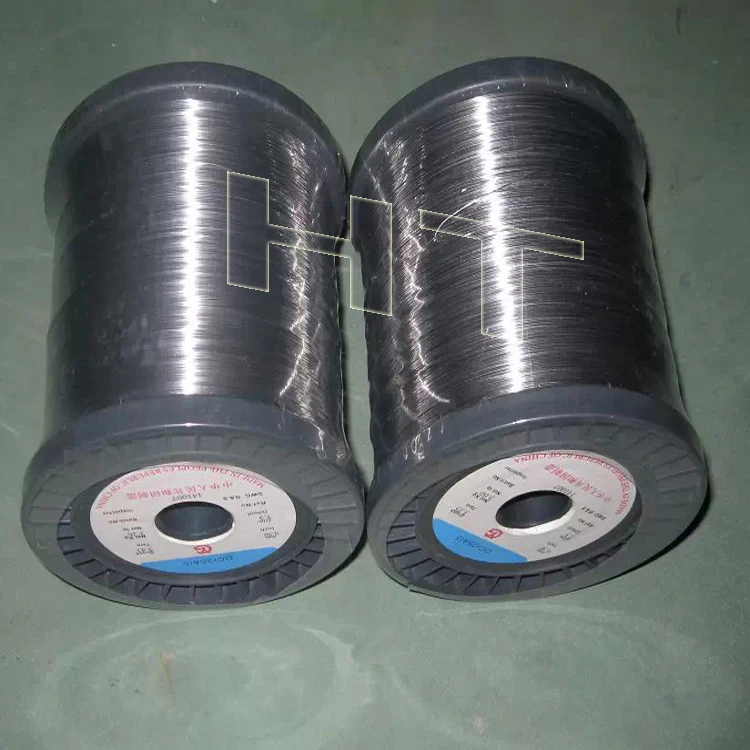

HT FeCrAl высокотемпературный сплав (OCr21Al6Nb) электрический нагревательный провод

- Категория: >>>

- Поставщик: Zhengzhou Hengtong Furnace Co. Ltd.

Сохранить в закладки 60759282193:

Описание и отзывы

Характеристики

FeCrAl wire.

we specializing in Ferro-Chrome (Fe-Cr-AL) heating resistance wire , Nickel-Chrome (Nichrome) heating resistance wire , Copper Nickel (Constantan) wire, and related products in alloys to meet specific customer requirements.FeCrAl alloys are characterized by excellent oxidation resistance and very good form stability resulting in long element life. They are typically used in electrical heating elements in industrial furnaces and home appliances.

FeCRAl wire Features .

1.FeCrAl Electrictrical Resistance Heating alloys with high electrical resistivity, temperature coefficient of resistance is small, high operating temperature. good corrosion resistance under high temperature, and particularly suitable for use in a gas containing sulfur and sulfides, low price, it is widely used in industrial electric furnace, household appliances, far infrared device ideal heating material.

FeCrAl type:1Cr13AI4, 0Cr21AI4, 0Cr21AI6, 0Cr25AI5, 0Cr21AI6 Nb, 0Cr27AI7Mo2 etc.Series electric flat belt, electric fire wire

Application .

FeCrAl alloy wire is typically used in industrial furnaces and home appliances. Examples of applications are elements embedded in ceramics for panel heaters, infrared heaters, warming plates, irons, ceramic pots, in cartridge heaters for liquid heating, storage heaters, in ceramic heaters for cooking plates, air guns, hobby kilns, radiators, in quartz tube heaters for space heating, toasters, toaster ovens, grills, industrial infrared dryers, coils on molded ceramic fibre for cooking plates with ceramic hobs.

FeCrAl 125: Low-cost heating element used in toasters and other small appliances. Long life performance for element operating temperatures up to 1150°C.

FeCrAl 135: Used as heating elements in hot plates, irons, electric furnaces, etc. Improved hot strength compared to 125 grade. Good for continuous element operating temperatures up to 1200°C. Also used in resistor applications and heavy relay switches.

FeCrAl 145: Used for industrial furnaces, kilns and other high temperature applications. Long-life for continuous operating temperatures up to 1300°C. Less increase in resistance on heating and higher oxidation resistance compared to other grades.

Packing .

packing in cartons and then in pallet

we will ship by sea,by air ,express .according the quantity and customer requirment

HT Furnace Company

Office

Workshop

1. The Leading manufacturer of nickel based alloy Porducts

2. The drafter & Reviser Of National Standard GB/T1234 regarding Electrothermal Alloy.

3. Over 10 years experience

4. Small quantity, short time delivery

If we have stocks, we can ship from a minimum of 1 kg sample in a few days.We also manufacture

custom-order materials in amounts of 100 kg and up (Some materials are allowed 50 kg) in as few as 3 weeks.

5. High-precision thickness

We guarantee thickness tolerances that cannot be reproduced by competitors.

Example: t <0.30mm Tolerance ±1 - 3 μm guaranteed

0.30 mm≤t Tolerance ± 1% guaranteed

6. complete QC system & Advanced physical and chemical testing center For each production processing, we have complete QC system for the chemical compostion and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods.

7. Effective and strong technical support and custom-made solutions.We provide customed solutions to your problems with our strong technologies and well versed knowledge of materials acquired through our more than 20 experience.

8. Choose the appropriate base metals for your needs

We carefully balance quality, delivery time and price,procure various base metals from all overthe world.We manufacture appropriate products to your needs.

9. Reliable certificate (ISO 9001/ROHS/BV/SGS/TUV)

Our products meet the standards, such as ASTM, ASME, AMS, DIN, JIS etc. The third party testingis available for us.

Похожие товары

Машина для горячего тиснения логотипа, машина для тиснения кожи

Машина для тиснения кожи пневматическая/зонтичная бронзовая машина/машина для горячего тиснения фольгой букв

Lixsun 6 шт. в наборе, украшение для кексов, мастики, украшение для торта, Топпер, помадка, впечатление, печенье, письмо, штамп, тиснение

Стеклянные бутылки делая логотип буквы горячей фольги ШТАМПОВКИ печатная машина автоматическая

Lixsun 6 шт. в наборе, украшение для кексов, мастики, украшение для торта, Топпер, помадка, впечатление, печенье, письмо, штамп, тиснение

Машина для горячего тиснения, ручная машина для тиснения кожаных и деревянных букв, быстрое изменение букв

Новые дизайнерские буквы с пластиковыми промежуточными трубками, сделано в Китае, наружная реклама, акриловые буквенные знаки

Новые поступления

Новинки товаров от производителей по оптовым ценам