Лидер продаж стержни нагревательного элемента из карбида кремния U образной формы ED DB HT

- Категория: >>>

- Поставщик: Zhengzhou Hengtong Furnace Co. Ltd.

Сохранить в закладки 60760466878:

Описание и отзывы

Характеристики

silicon carbide heating element .

The silicon carbide heating element is a kind of non-metal rod or tube shape high temperature electric heating element. It is made of selected super purity green hexagonal silicon carbide as main material, which is made into blank and silicon crystal under high temperature of 2400ºC. In oxidizing atmosphere, its service temperature can reach 1450°C and continuous use life can reach 2000 hours.

Type: we have rod, u, w, h, gun, single spiral, double spiral, dumbbell, door like type

Size:

2. Heating Zone Lengh (HZ )

3. Cold Zone Lengh(CZ)

4. Overall Length (OL)

5. Resistance you need.

Order Sample: U-type, HZ200mm, CZ150mm, OL350mm, Resistance 0.4ohms

Features.

1. High strength and excellent shock resistance;

2. Heat source is free of noise and air pollution;

3. Anti-oxidization; 4. Anti-corrosion, 5. Long service life

6. Little deformation, 7. Easy installation and maintenance.

8. Excellent specific rate of heat zone resistance and cold end resistance,

9. Avoiding over-temperature of cold ends to damage the furnace body. 10. Saving energy

ED type .

Silicon Carbides are used in applications ranging in temperature from 600°C up to 1400°C in both air and controlled atmospheres. the type of atmosphere used will determine the maximum recommended element temperature. This kind of silicon carbide elements can be mounted either vertically or horizontally.

U type .

U shape Silicon Carbide is consists of two silicon carbide rod with same diameter. Each rod has both hot zone and cold end with identical resistance. Two rods are connected by the low resistance SiC. Also the connector could be used as holder according to different requirements.

W type

3-phase elements are available in 2 different types: SGC (Dumbbell), SGD(Standard).

These elements are self-bonded silicon carbide formed by re-crystallization of silicon carbide at high temperature. It consists of three high-purity silicon carbide rods connected at one end by a silicon carbide crossbar.

Application .

==Silicon carbide Uses==

1.As the use of silicon carbide, high temperature, high temperature, anti-oxidation, corrosion-resistant, fast heating, long life, high temperature deformation, easy installation and maintenance features. Good chemical stability. .

2.Hard and brittle texture components, thermal shock resistance, high temperature deformation is not easy

3. Silicon carbide has good chemical stability, strong acid resistance. Its aggressive alkaline substance at elevated temperature conditions.

Notice for using and installing of silicon carbide heating element.

1. Heater should be protected against damp during storing or installing to ensure the performance of the heater.

2. In order to be sure of well-distributed lod of each and groups, heater should be divided before assembling. The tolerance of the resistance of each one cannot exceed by 10% each other.

3. Heater is hard and brittle, please be careful when assembling and maintaining so as to avoid damage.

4. When operating the electric furnace at the beginning, the voltage should be increased slowly and cannot be fully loaded at once. Otherwise the larger current will be resulted in the damage of heater.

5. When heater is damaged and need to be changed, the resistance of new one should follow the increasing resistance. If many are damaged or resistance increased too much, heater should be changed.

HT Furnace Company .

HT office

HT Workshop

Customer visit our company

siclion carbide heating element

1.Timely response,

Timely response to your inquiry, multiple choice recommendations based on your demand,quickly respond mails and provide solutions.

2.Free sample

silicon carbide heating element Sample and trial order are accepted for the quality evaluation

3.Strict quality control

Arrange production on time and control quality strictly.

4.Shorter delivery time.

Book the earliest vessel or plane to guarantee the delivery time.

5.Professional Services

Provide all the detailed news and pictures from order to delivery;

Offer relative export documents and original certificate if needed;

Warm and considerable after-sale service

What is your delivery time ?

For some normal standard size furnaces and components, we have in stock; So we can send out in 2-3 days; Other customized sizes the delivery time is from 15 days to 30 days according to different products request.

What is your advantage ?

We are a manufacturer in China. So we can control the cost well.

We use the top material in our furnace, imported ceramic fiber and accurancy temperature controller.

We supply good service after sale, you can be assured about that.

How many years have you been in this field?

We have been manufacturing in this fields more than 10 years.

Похожие товары

Банка для специй, герметичная вакуумная герметичная банка для кофе из нержавеющей стали

Цветной конус уход за ушами ароматическое свечение ушей массаж ароматерапия различные формы и ароматы нетоксичный ароматизатор Ушная свеча

Детский колокольчик с двумя в одном звуком, бубен, музыкальный свет, ручная погремушка, игрушечный набор для ребенка, музыкальная игрушка, пластик, ABS

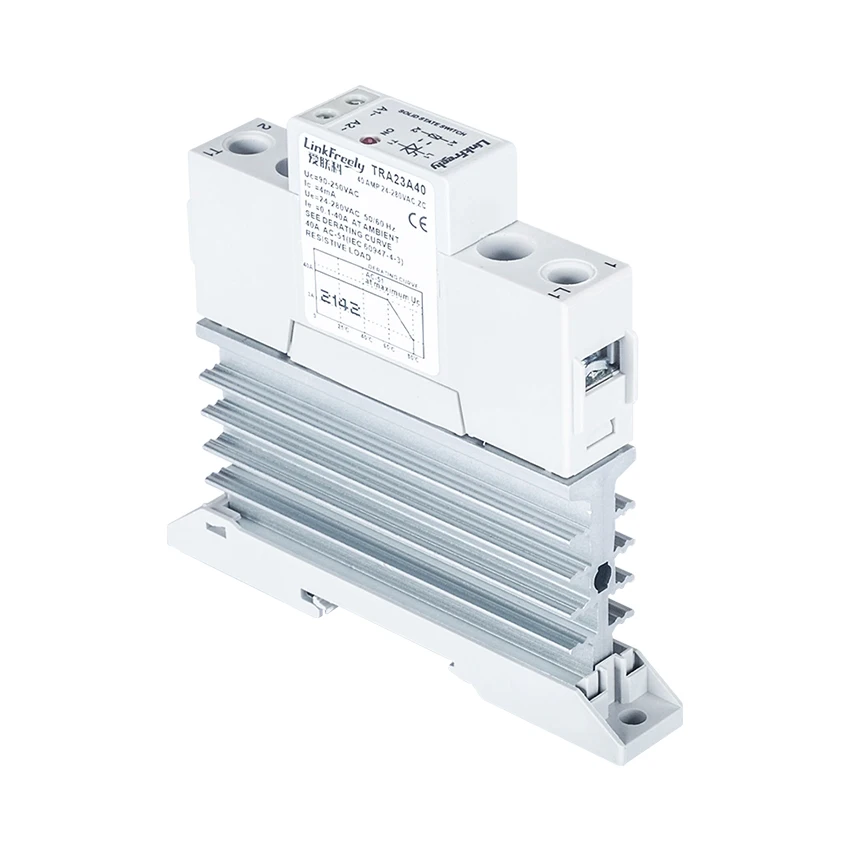

Твердотельное реле TRA23A40L 40A, радиатор переменного тока, 90-250 В переменного тока, Входное реле, Модуль платы контроля напряжения 24-280 В переменного тока, Din-рейка

CAMMUS SIM гоночный симулятор базовый прямой привод серводвигатель с регулировкой приложения

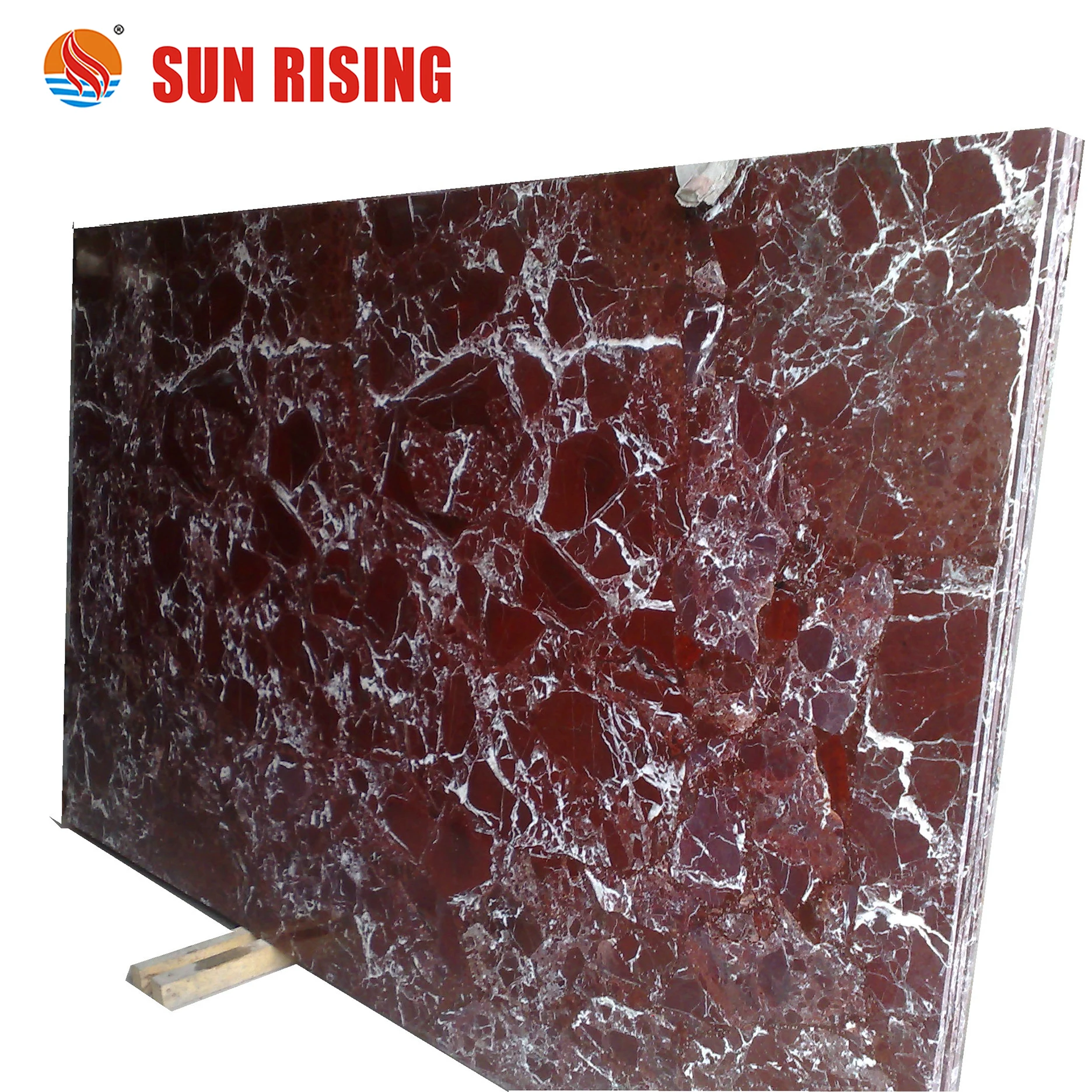

Популярный натуральный камень, Роза Levanto, красный мрамор для напольной плитки

Подержанные сиденья для кинотеатра с наклоном сзади Лидер

Новые поступления

Новинки товаров от производителей по оптовым ценам