HT карбид кремния/SIC тигли для

- Категория: Тигель графитовый >>>

- Поставщик: Zhengzhou Hengtong Furnace Co. Ltd.

Сохранить в закладки 60761121526:

Описание и отзывы

Характеристики

HT-silicon carbide/SIC crucibles for melting

Features of silicon carbide crucible:

a)Excellent Thermal Shock Characteristics

b)Corrosion Resistance

c)As Cast Tight Dimensional Tolerances

d)High Creep Resistance

e)Superior Wear Resistance

f)Maximum Use Temperature to 1600 °C

g)High temperature tolerance, high thermal conductivity, low coefficient of thermal expansion, oxidation resistance, thermal shock resistance, long application life.

Benefits:

a)Superior Oxidation Resistance

b)Improved Performance

c)Lowered Cost Burden

d)Longer Life Between Replacement/Rebuilds

e)Allows Lower Weight

f)Very High Thermal Conductivity

1.Thermal stability: We make special design to assure the quality accordig to the instant temperature changing working condition.

2.Corrosion resistance: Precise design extends the ability of corrision resistance of the crucible.

3.Impulsion resistance: Duratight graphite crucible can stand very strong heat impulsion, so it can be freely used in any technic process.

4.Acid resistance: Impregnation of special stuff can improve the quality of the crucible and its outstand in the acid resistance. As a result, it can prolong the work life of the graphite crucible.

5.Fine thermal conductivity: High content of fixed carbon ensures the good thermal conductivity, shorten the dissolving time and lower the cost of the oil and other energy obviously.

6.Control of metallic pollution : Strict control of the contents assures that there is no pollution to the metal during dissolving.

7.Quality stability: High-pressure manufacturing method and quality control system can pledge the quality stability better.

Chemical Composition of sta silicon crucibles

C % | SiC% | AL2O3 % | SIO2% |

45%-50% | 20%-30% | 10%-12% | 15-25% |

The specification of sta silicon crucibles:

Content of C | ≥ 45 |

Density(g/cm3) | ≥ 1.85 |

Apparent porosity (%) | ≤ 21 |

pressive strength(Mpa) | ≥ 25 |

refractability | ≥ 1400C(melting alumina) ≥ 1550C(melting copper) |

rupture strength(Mpa) | 9-12 |

diathermancy | 3.0-3.7×10-6/C |

C | 45-50% |

Sic | 20-30% |

Sio2 | 15-25% |

Si | 3-8% |

A12O3 | 10-12% |

Похожие товары

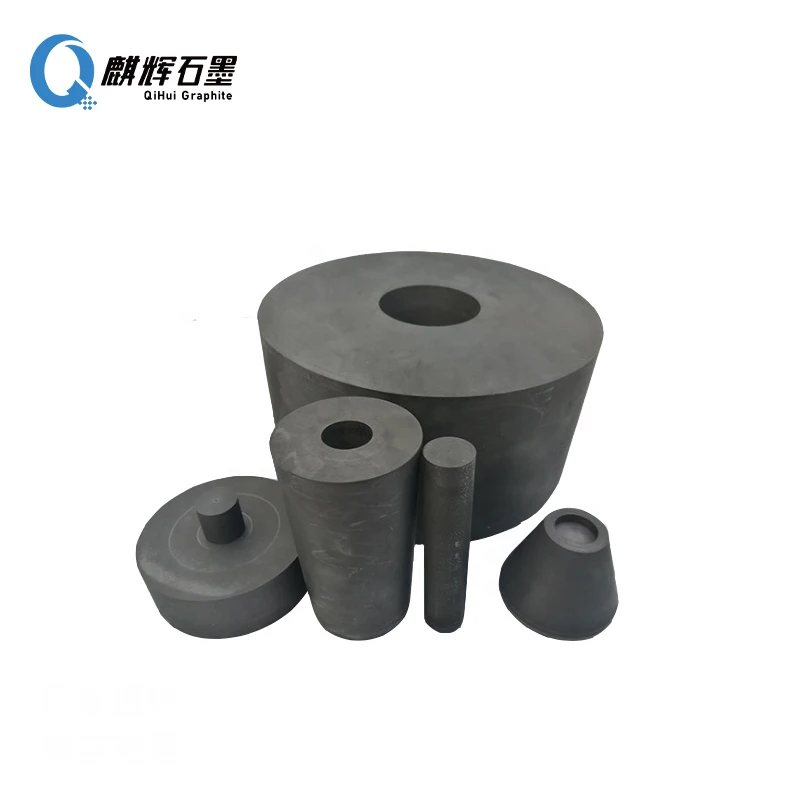

Изготовленная на заказ графитовая пресс-форма Qihui

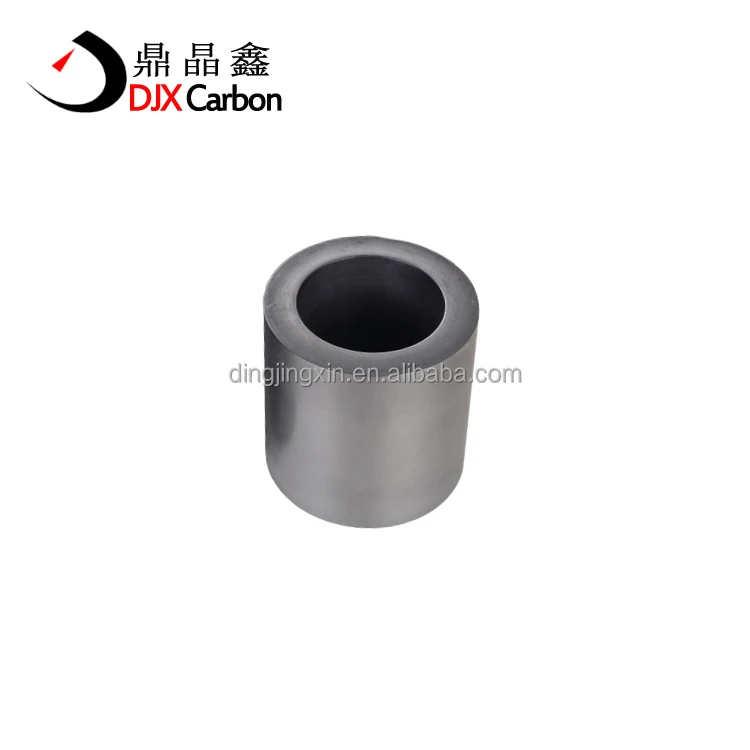

Графит Sic плавильный котелок для

Индукционная печь высокой чистоты 2 кг 3 кг графитовый тигель для плавления золота с крышкой

Плавильный золотой слиток огнеупорный графитовый тигель

Графитовый тигель, плавильный металл, высокочистый графитовый материал, изостатический на заказ, 30-40 МПа, мин. 30 мм, 50 мм, 0,8 мм/325 сетка 0.09%

Тигель высокой плотности синтетический искусственный графит

Лучшие продажи отличная теплопроводность литья графитовый тигель для испарения электронного

Новые поступления

Новинки товаров от производителей по оптовым ценам