Прямая продажа с завода трубка из экструдированного поролона и силиконовой резины

- Категория: >>>

- Поставщик: Shenzhen Synch Silicone Products Co. Ltd.

Сохранить в закладки 60761965536:

Описание и отзывы

Характеристики

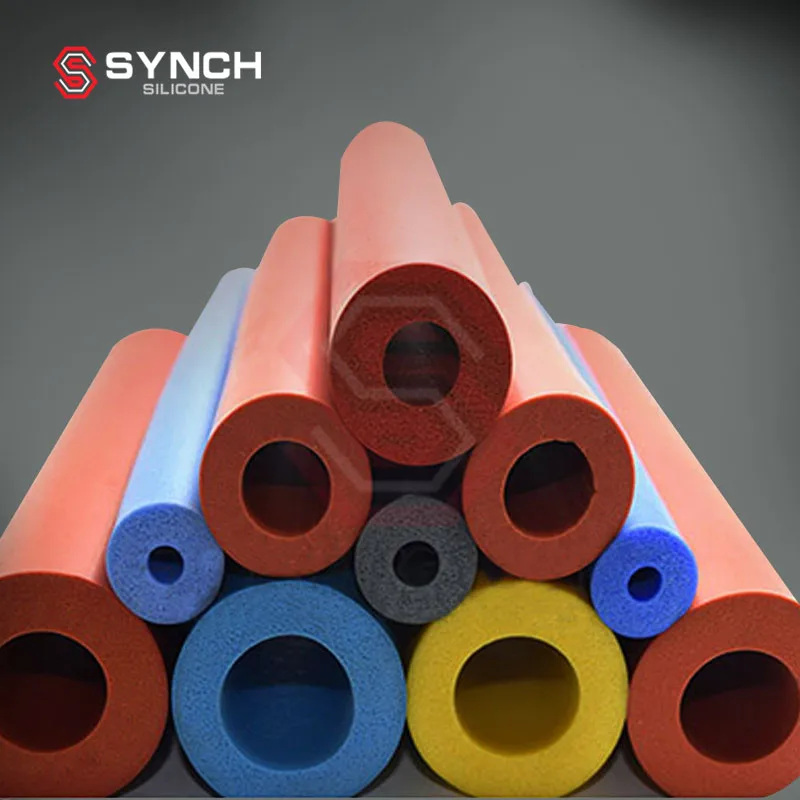

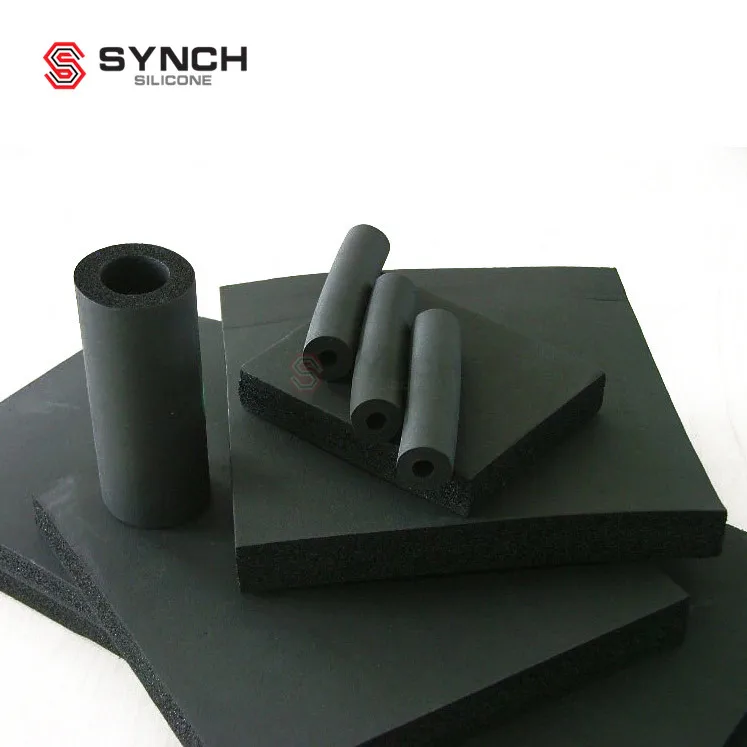

Factory Direct Supply Silicone Rubber Extruded Sponge Tube

SYNCH manufactures Silicone sponge tube with a wide verity of extruded high-quality standard and all customized size silicone sponge tube. We can manufacture Silicone Sponge tube to specific size for customer needs, our product is manufacturing under the strict supervision of our quality production team to make sure the extruded products meet customers' specific requirements.

Silicone sponge tube/cord has universal application across a wide range of industries and markets. Sponge tube/cord has fantastic compression set values. They are particularly suited to use in high temperature seals and gaskets, where a soft, easily deformed rubber is required.

Description | Silicone Sponge Tube |

Material | 100% Eco-friendly silicone foam |

Shore Hardness | 10~30 degrees |

Density | 0.3~0.95g/cm3 |

Color | Black, blue, grey, green, any color, etc. |

Tensile Strength | 10-30psi |

Temperature Resistance | -60°C to 250°C |

Features | Eco-friendly, non-toxic, safe, high temperature resistant, non-sticky, anti-aging, excellent insulating property, etc. |

Processing method | High temperature curing and foaming |

Delivery time | 10-20 days if there is no stock |

Package | PVC wrap or customized (cut in length at 3mm min. or roll at 50m or 100m) |

Application | Electrical Enclosure Seals Insulation Outdoor Lighting Gaskets HVAC Seals Door Seals Outdoor Digital Signage |

Features:

• Excellent UV and Ozone resistance

• Closed Cell

• Odorless & Test-less

• Superiors/High Tear Strength

• High & Low Temperature Rating

Our Advantages:

• Wide variety of size, shapes and hardness.

• Quality that stands out.

• Competitive factory price.

• Friendly customer support.

• Promise of on time delivery.

• For your silicone sponge tubing requirements, contact us now!

Q1: Do you have your own factory?

A:Yes, we have our own factory established more than 12 years.

Q2: Silicone seems to be more expensive than other rubber, why is this?

A: Silicone is more expensive than most rubber types because it is a speciality high performance

polymer with outstanding qualities. It is made in relatively low quantities and requires expensive

and complicated primary manufacturing facilities.

Q3: What is the difference between 'curing' and 'vulcanization'?

A: The terms curing and vulcanization essentially describe the same thing - the transformation of

the polymer into a cross-linked rubber.

Q4: Why is silicone used in food applications?

A: Silicone rubber is among a number of rubber types that can be used in contact with food. It has

the advantage of being a low taint non-toxic material.

Q5: Do you provide sample? Is it for free or not?

A: Yes, if we have it in stock we can offer the sample for free, while you need to pay for the freight

cost to your country.

Q6: When can you launch delivery after I placed order?

A: If there is stock, 2-5 days; if not, 15-30 days depends on the quantity.

Похожие товары

Латунная Лампа для майнинга антикварная отделка с белым стеклом

Черный нижний напорный ролик для магазина принтеров Brother HL5240 5250

30 мл квадратная полипропиленовая пластиковая косметическая бутылка для солнцезащитного крема, флакон для лосьона, пустой косметический матовый контейнер для BB крема

Клеевой пистолет со стальным триггером, 9 дюймов, 310 мл, 10 унций, Н

Персонализированная металлическая мешалка для коктейлей с горячим шоколадом для кухни

Генератор переменного тока, номер детали 1800A387

PEMF терапия Электротерапия Машина реабилитационная терапия машина кровяная вязкость оборудование давление низкоуровневый лазер

Новые поступления

Новинки товаров от производителей по оптовым ценам