Машина для выдувного формования пластиковых бутылок объемом 20 литров JS600D

- Категория: Выдувная машина >>>

- Поставщик: Taizhou Jiansheng Machinery Co. Ltd.

Сохранить в закладки 60773844500:

Описание и отзывы

Характеристики

Product Description

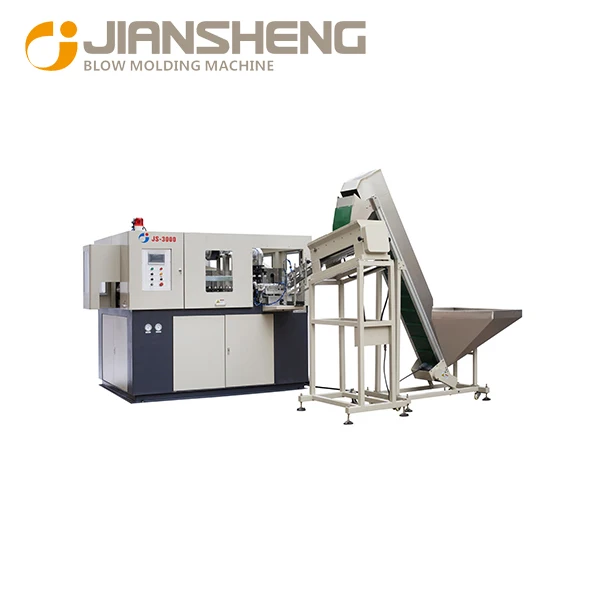

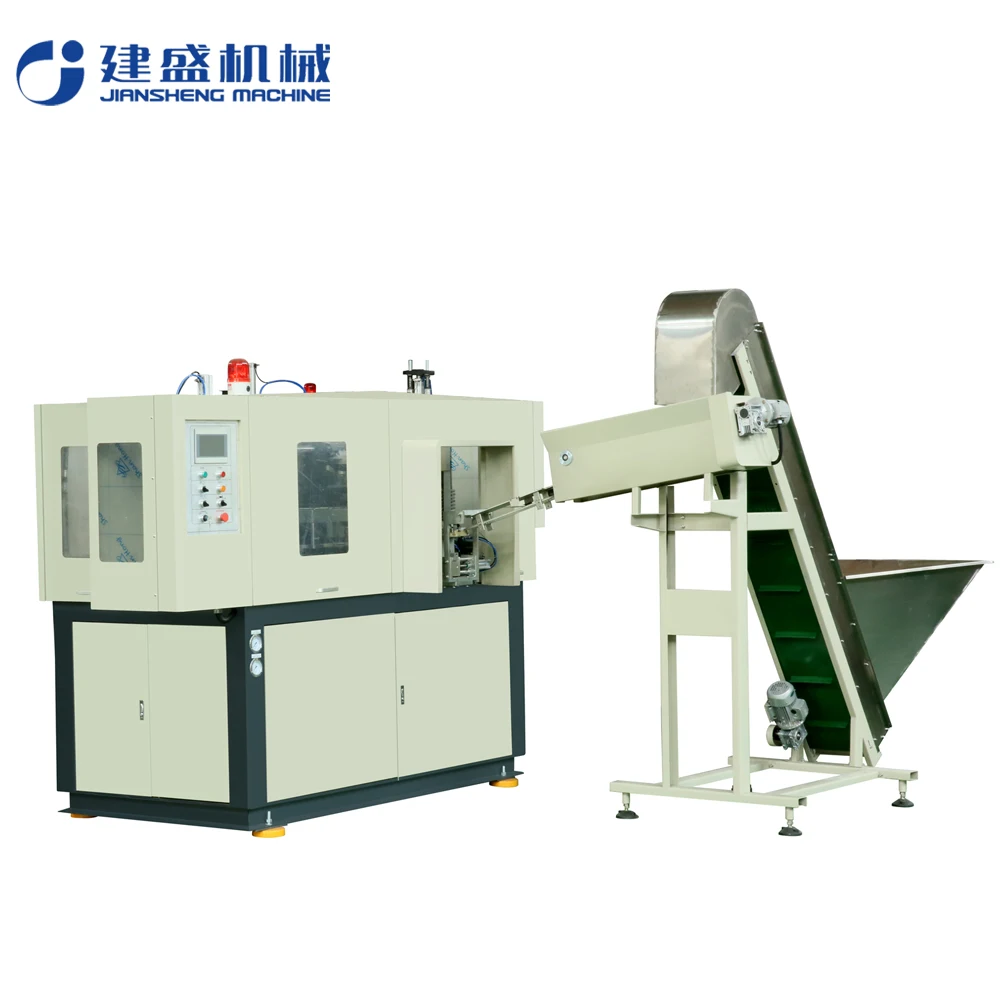

JS-600D full automatic blow molding machine for making big oil bottles 20L,700BPH,1cavity

And also good choice for making 5 gallon water bottles.

Fast speed,stable function,long service life

1.JS Bottle Making Machine With touch screen, Use Festo ( German brand) , SMC (Japan brand )& Parker ( U.S.A Brand) pneumatic

components. PLC use Mitsubishi (Japan brand)

2. Nontoxic conveyor belt to carry preforms

3. Produce PET Bottles ( such as: wine, beverage, soybean, vinegar bottles and so on)

4. Easy to maintain

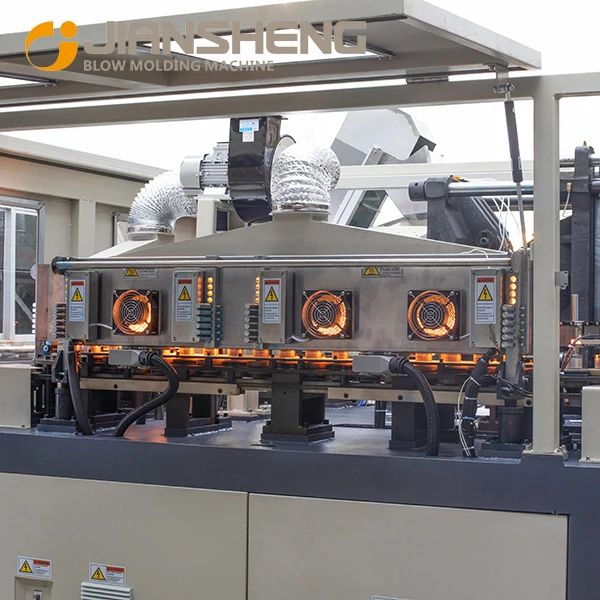

5. Infrared lamps

6. High safety. high speed with high efficiency.

7. Manual saving, one man is enough for operation the machine.

8. Stable performing with easy maintaining.

9. Imported PLC controlling and man-machine interface computer.

10. Japan Omron inspection sensor.

11. Adopt the new type double bend arm and the four rod-clamping structure(won the patent): Cross direction; Middle mould board is

move parallel; the distance between two mold board is adjusted by the chain wheel. Thus, the clamping force is very strong.

12. Power saving design that can increase your profits.

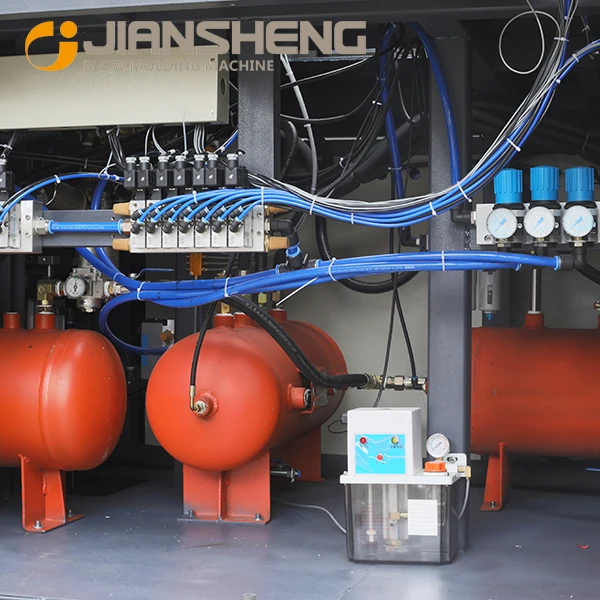

13. Segregate type air controlling system, which is designed for avoiding waste pollution.

components. PLC use Mitsubishi (Japan brand)

2. Nontoxic conveyor belt to carry preforms

3. Produce PET Bottles ( such as: wine, beverage, soybean, vinegar bottles and so on)

4. Easy to maintain

5. Infrared lamps

6. High safety. high speed with high efficiency.

7. Manual saving, one man is enough for operation the machine.

8. Stable performing with easy maintaining.

9. Imported PLC controlling and man-machine interface computer.

10. Japan Omron inspection sensor.

11. Adopt the new type double bend arm and the four rod-clamping structure(won the patent): Cross direction; Middle mould board is

move parallel; the distance between two mold board is adjusted by the chain wheel. Thus, the clamping force is very strong.

12. Power saving design that can increase your profits.

13. Segregate type air controlling system, which is designed for avoiding waste pollution.

Specification

Company Profile

Packing & Delivery

JIANSHENG MACHINE

1 / A standardized workshop with a total area of 20,000 square meters.2/Founded in 2004,has 17 years of experience in blow molding

machines.

3 / Located in Taizhou only 120km from Ningbo.

4/ The equipment will be tested and run for 24 hours before leaving the factory to ensure the smooth operation of the water

pipeline and the stability of the pneumatic, electrical and mechanical.

5/The spare parts inventory is sufficient to ensure timely delivery and supply of spare parts.

JIANGSHENG Machine Sales Manager Team and Engineer Team.

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2 / The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as

per customers' requirements to save space.

1 / A standardized workshop with a total area of 20,000 square meters.2/Founded in 2004,has 17 years of experience in blow molding

machines.

3 / Located in Taizhou only 120km from Ningbo.

4/ The equipment will be tested and run for 24 hours before leaving the factory to ensure the smooth operation of the water

pipeline and the stability of the pneumatic, electrical and mechanical.

5/The spare parts inventory is sufficient to ensure timely delivery and supply of spare parts.

JIANGSHENG Machine Sales Manager Team and Engineer Team.

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2 / The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as

per customers' requirements to save space.

After service:

1.Installation, debug We will arrange seasoned technician for debug and test production at the same time make the equipment reach

the rated producing capacity of the line.

2. Training Our company offer technology training to customer. The content of training is structure and maintenance of equipment,

control and operation of equipment. After training, the technician of buyer could master the operation and maintenance, could

adjust the process and treat different failures.

3.the sample service

1'We can send you the video of the running machine.

2'You are welcome to come to visit our factory,and see the machine running.

4.We can design the machines according your requirements,at the same time we will give you our professional suggestion,as you

know,we have been in this industry for 12 years.

5.well-trained & experienced staff are to answer all your inquiries in English and Chinese

6 .12 Months guarantee and life-long technical support.

7.Your business relationship with us will be confidential to any third party.

8. Good after-sale service offered, please get back to us if you got any questions

1.Installation, debug We will arrange seasoned technician for debug and test production at the same time make the equipment reach

the rated producing capacity of the line.

2. Training Our company offer technology training to customer. The content of training is structure and maintenance of equipment,

control and operation of equipment. After training, the technician of buyer could master the operation and maintenance, could

adjust the process and treat different failures.

3.the sample service

1'We can send you the video of the running machine.

2'You are welcome to come to visit our factory,and see the machine running.

4.We can design the machines according your requirements,at the same time we will give you our professional suggestion,as you

know,we have been in this industry for 12 years.

5.well-trained & experienced staff are to answer all your inquiries in English and Chinese

6 .12 Months guarantee and life-long technical support.

7.Your business relationship with us will be confidential to any third party.

8. Good after-sale service offered, please get back to us if you got any questions

FAQ

1.Your company is a trading company or a direct factory?

We are a direct factory located in TAIZHOU City. Very close to NINGBO and Wuxi (airport and train provided). If you arrive

in Ningbo, we can pick you up to visit our factory.

2.If we buy your machine, what is your guarantee or guarantee of quality?

We provide you with high-quality machines with 1-year warranty and lifetime technical support.

3.How to ensure the safety of your funds and deliver on time?

1/Through Alibaba's letter guarantee service, it will ensure on-time delivery and the quality of the equipment to be purchased.

2/Through the letter of credit, you can easily lock the delivery time.

3/After visiting the factory, you can ensure the authenticity of our bank account.

4.Check how JIANGSHENG MACHINE ensures quality!

1/In order to ensure the accuracy of each part, we are equipped with various professional processing equipment, and we have

accumulated professional processing methods in the past few years.

2/Each component before assembly needs to be strictly controlled by inspectors.

3/After all equipment is completed, we will connect all machines and run the entire production line for at least 12 hours to

ensure the stable operation of the customer’s factory.

We are a direct factory located in TAIZHOU City. Very close to NINGBO and Wuxi (airport and train provided). If you arrive

in Ningbo, we can pick you up to visit our factory.

2.If we buy your machine, what is your guarantee or guarantee of quality?

We provide you with high-quality machines with 1-year warranty and lifetime technical support.

3.How to ensure the safety of your funds and deliver on time?

1/Through Alibaba's letter guarantee service, it will ensure on-time delivery and the quality of the equipment to be purchased.

2/Through the letter of credit, you can easily lock the delivery time.

3/After visiting the factory, you can ensure the authenticity of our bank account.

4.Check how JIANGSHENG MACHINE ensures quality!

1/In order to ensure the accuracy of each part, we are equipped with various professional processing equipment, and we have

accumulated professional processing methods in the past few years.

2/Each component before assembly needs to be strictly controlled by inspectors.

3/After all equipment is completed, we will connect all machines and run the entire production line for at least 12 hours to

ensure the stable operation of the customer’s factory.

Похожие товары

JS-600D машина для выдувания бутылок цена

48 000,00 $ - 52 000,00 $

JS-2II-PP полуавтоматическая цены по прейскуранту завода-изготовителя пластиковый материал pp бутылка выдувного формования делая машину

JS-600C пластиковая выдувная формовочная машина

27 500,00 $ - 30 000,00 $

Заводская цена, 2 л, 800 шт./ч, полуавтоматическая машина для производства бутылок из ПЭТ, цена

3 720,00 $

JS-600D 10L-20L бутылка для воды масло косметика парфюмерия диспенсер супер большой емкости машина для выдувания бутылок

1 полость 5 литров полуавтоматическая hdpe бутылки делая машину JS-5 стрейч воздуходувка

6 000,00 $ - 9 000,00 $

Заводская цена, 5 л воды, машина для выдувания бутылок с кулинарным маслом из ПЭТ

55 500,00 $ - 57 000,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $