Ротогравюрная печатная машина гравюрная Печать Цилиндр цена

- Категория: >>>

- Поставщик: Jctprint Machinery Co. Ltd.Jctprint Ltd.

Сохранить в закладки 60776106868:

Описание и отзывы

Характеристики

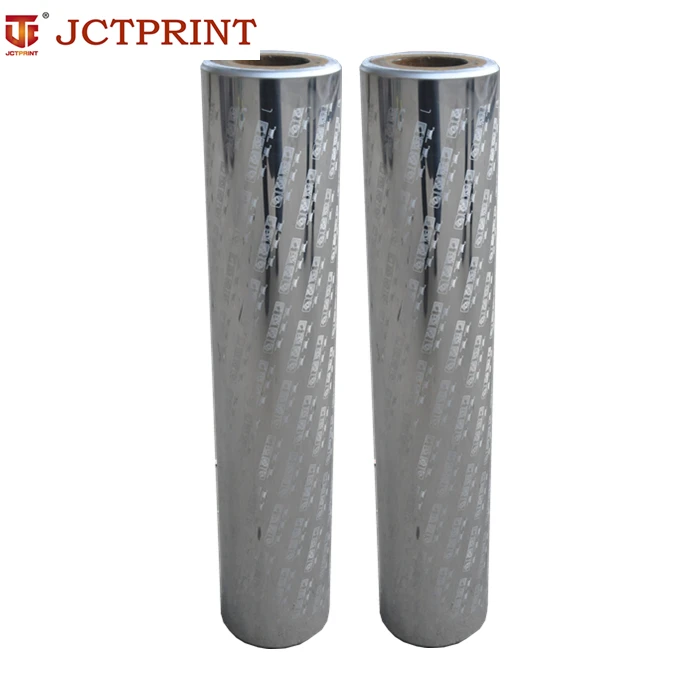

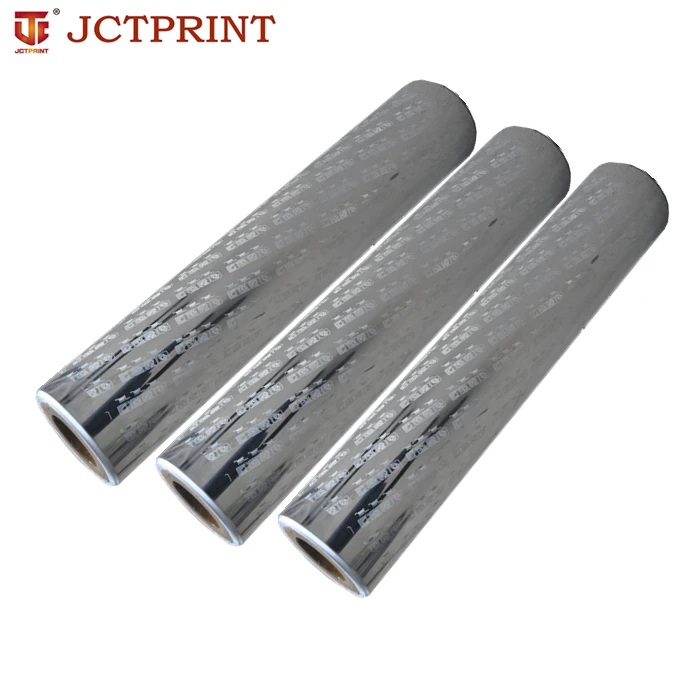

Best price rotogravure printing machine engraving cylinders

1.Application

| Plastic packaging printing | Plastic material like PE,PET,BOPP, OPP and so on. bottle label or all kinds of bags |

| Aluminum foil printing | Medicine packaging ,beer labels(on the neck and the seal label) |

| Metalized paper printing | Wet strength paper,beer label(on the body and back),Cigarette packaging(coated paper, cardboard, Laser paper to make cigarette package) |

| Special material printing | Laser Anti-counterfeit,,wood grain and so on. |

2.Process of gravure printing cylinders

→Image design and graphic design after receive customer’s requirement

→Mechanical treatment

→Copper plating

→Electric carving

→Chroming

→Printing sample making

→Exfactory inspection

→Packaging and delivery

3. Features

A.Circumference of the cylinder: 100-1500mm

Width of the cylinder: 50-8200mm,normally 50mm longer than the rubber roller on the machine.

B.Precision on the cylinder production

Surface Hardness | ≥HRC50,with strong corrosion resistance |

Roughness | ≥ Ra0.16 |

Temperature difference | ≤±1°C |

Thermal deformation | ≤0.01mm |

Concentricity | 0-15microns |

Straightness | ≤0.2mm |

Cylindricity | ≤0.2mm |

4.Advantages of our cylinders

A. High-quality materials for base roller:

We adopt 45# seamless steel tube as the base roller,which have enough stiffness to make sure the bending deflection is not over the allowable value under heavy pressure.

B. Dynamic balance test twice

We will do dynamic balance test twice on each cylinders,the radial jumped error will be less than±0.005,which will help do evenly distribution of the inks on the printing material.

C. Heating treatment process

This process will increased hardness and to prevent the cylinder from deformation and will assure the geometric accuracy and long service life.

D. Packaging

We use plywood cases and wollen blanket to protect the cylinders.And we will also smear anti-rust oil on the cylinder surface which will help prevent surface oxidizing and rusting under moisture.

5.Why choose us?

1)We have over 20 years experience to produce cylinders.

2)We have the professional design teams to serve customers,surface and reverse printing available.

3)We have the strict quality system to make sure the quality of every process.

4)We can assure fast time of delivery---7-10 days after payment and color separation file confirmed.

1. How many years have you been producing gravure printing cylinderss?

As the leading manufacturer of gravure printing cylinderss,we have been in this field for more than 10years,and we have plenty experience in making rollers such as gravure printing cylinderss,ceramic anilox rollers,rubber rollers and so on.

2. Why choose us?

We can provide you not only the competitive price product but also most satisfactory supporting service.

3. How can we get the price?

A. Your printing material:Aluminum foil, plastic or metallized paper

B. You cylinder width(face length), circumference(diameter)

C. The design documents

4. How long is the lead time?

Usually it will take 7-10 days to produce the cylinder,but it also depends on the quantity and customer’s requirement.

Похожие товары

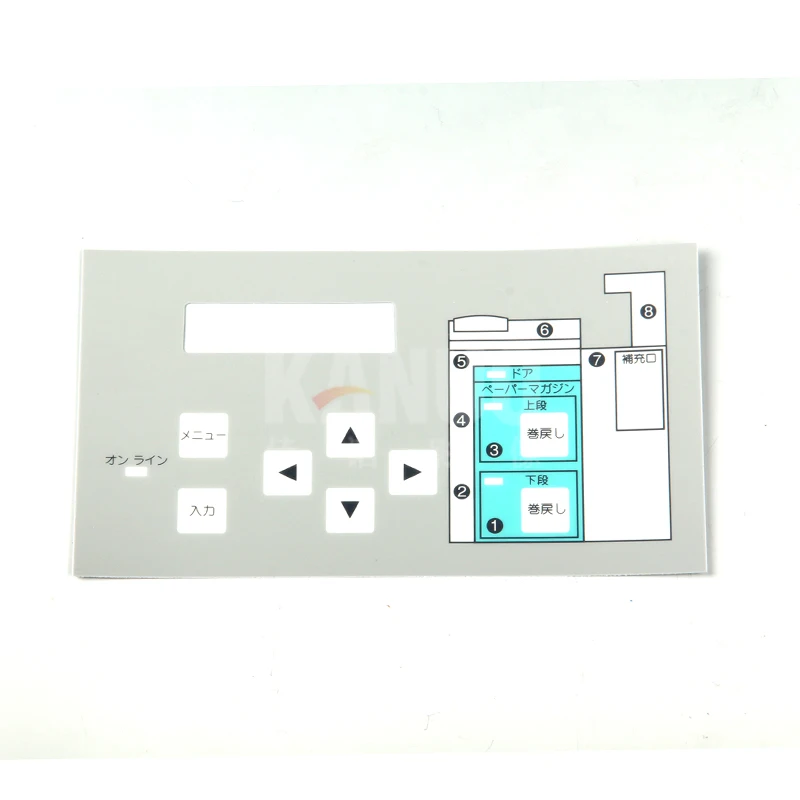

Используемая печатная плата CTL23 для fuji frontier 550 550R цифровая минилаба фотомашина принтер

FUJI FRONTIER 390 minilab 402S0014 резьбовые сильфонные с тарельчатыми клапанами

Пленочный процессор Fuji Frontier minilab FP563SC N1 приводной ремень

Наложение клавиатуры для 355 350 Fuji 370 сканер Frontier minilab японский

Fuji 550 350 Minilab GDM23 память 113C1099227 б/у

Fuji minilab часть 356D890216

327C966214 327C966214C Gear Fuji 330 340 Frontier minilab

Новые поступления

Новинки товаров от производителей по оптовым ценам