Многофункциональная машина для ламинирования полиуретанового термоплавкого

- Категория: Apparel & Textile Machinery >>>

- Поставщик: Jiangsu Xinlilong Light Chemical Equipment Co. Ltd.

Сохранить в закладки 60778558682:

Описание и отзывы

Характеристики

HOT MELT PUR LAMINATING MACHINE CONCEPT:

In industrial use, hot melt adhesives provide several advantages over solvent-based adhesives. Volatile organic compounds are reduced or eliminated, and the drying or curing step is eliminated. Hot melt adhesives have long shelf life and usually can be disposed of without special precautions.

The most advanced hot melt adhesive, moisture reactive hot melt glue (PUR & TPU), is highly adhesive and environmentally friendly. It can be used for lamination of 99.9% textiles. The laminated material is soft and high temperature resistant. After moisture reaction, the material will not be easily affected by the temperature. Besides, with lasting elasticity, the laminated material is wearresistant, oil resistant and aging resistant. Especially, mist performance, neutral color and other various features of PUR makes medical industry application possible.

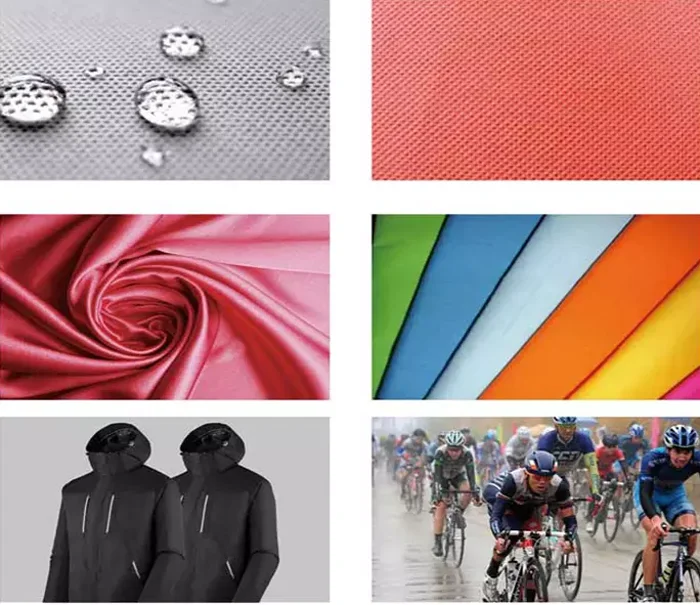

LAMINATING MATERIALS:

1.Fabric + fabric:textiles, jersey, fleece, Nylon, Velvet, Terry cloth, Suede,etc.

2.Fabric + films, such as PU film, TPU film, PE film, PVC film, PTFE film,etc.

3.Fabric+ Leather/Artificial Leather,etc.

4.Fabric + Nonwoven

5.Diving Fabric

6.Sponge/ Foam with Fabric/ Artificial Leather

7.Plastics

8.EVA+PVC

WIDELY USED IN:

This hot melt laminating machine adopts hot melt glue to laminating two layers of material, such as:

fabric, leather, film, nonwoven, EVA, etc.

It is suitable for many industries, such as:

Automobile industry : car ceiling decoration material, laminated fabrics of door post and door panel,etc

Garment industry : outdoor sports ,camouflage clothes, fire and police clothing, medical clothing, protective clothing ,functional garments like bar ,wetsuit , thermal cloth,etc.

Shoe-making industry :shoe vamp, shoe pad ,shoe-making materials.

Health care : medical and protective apparel,etc

Filter material : PTFE, PE film processing, for sewage and air filtration.

APPLICATION AND FEATURES OF HOT MELT LAMINATING MACHINE:

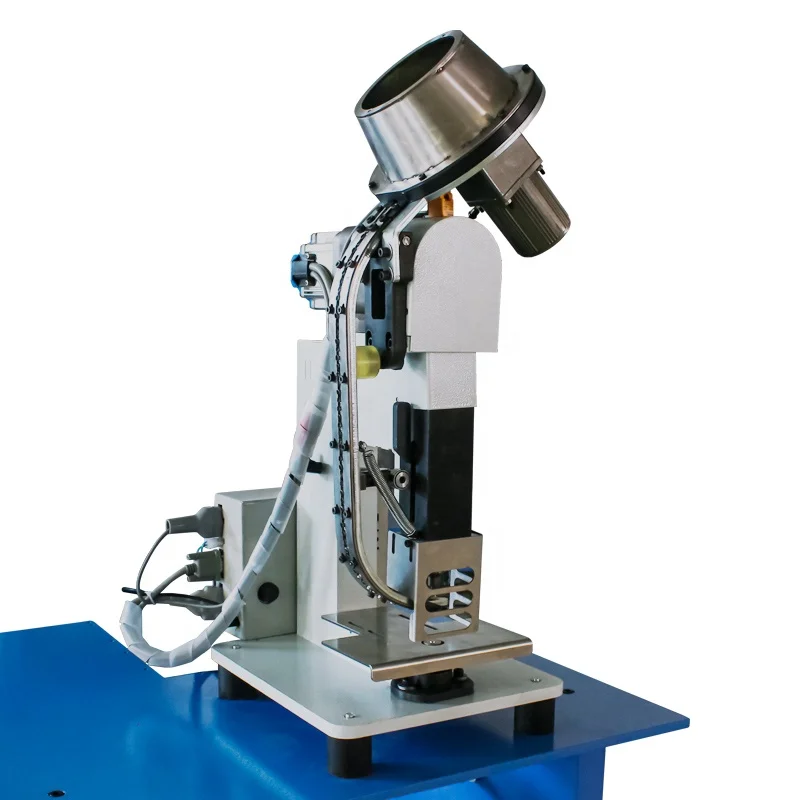

1. Applied for gluing and laminating of hot melt glue onto textiles and nonwoven materials.

2. Hot melt adhesives makes possible environmental friendly products and realizes no pollution during the whole process of lamination.

3. It's of good adhesive property,flexibility,thermostability,non-cracking property at low temperature.

4. Controlled by Programmable Logic Controller system with touch screen and modular designed structure, this machine can be easily and simply operated.

5. Famous brand motors and inverters can be installed for stable machine performance

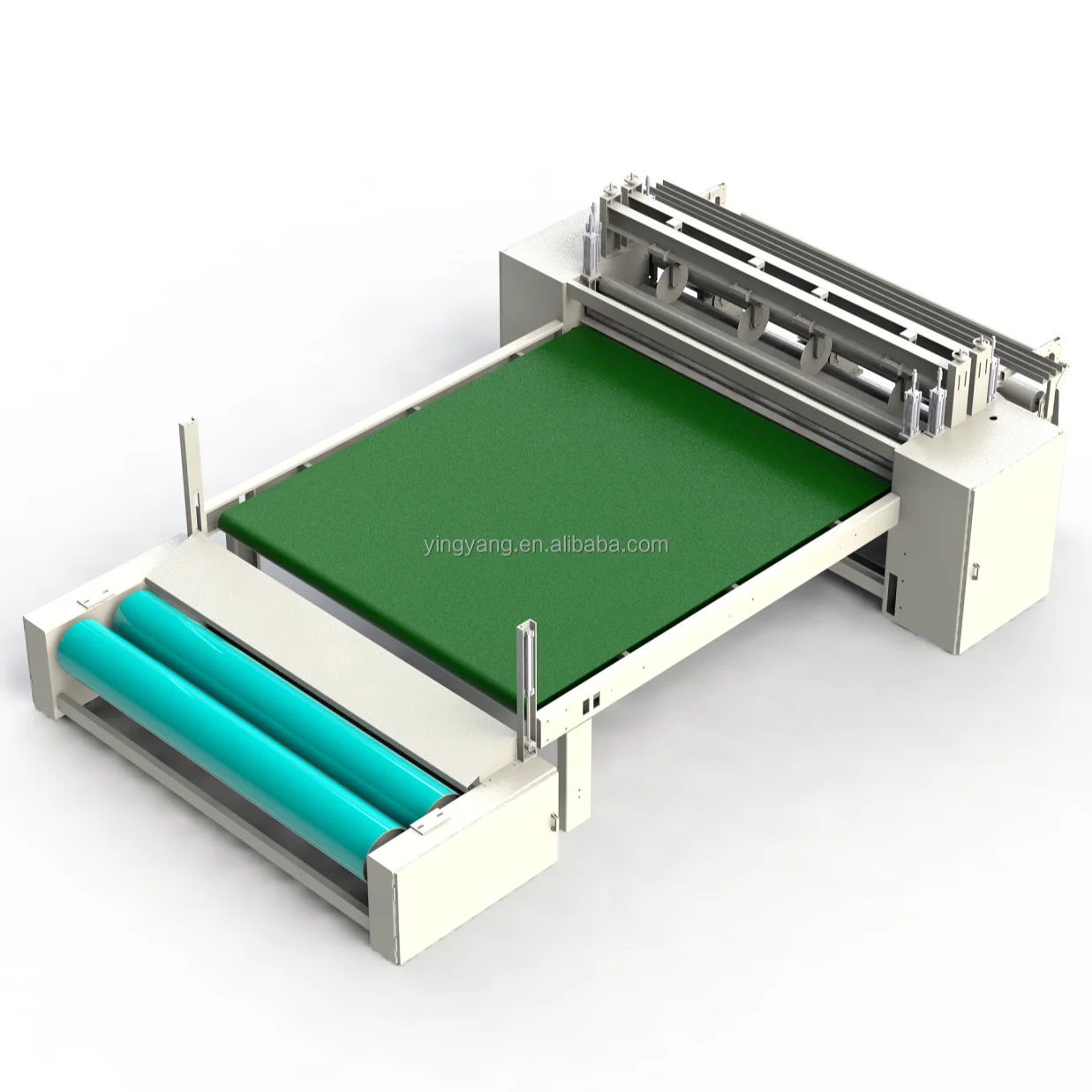

6. Non-tension unwinding unit makes laminated materials smooth and flat, guaranteeing good bonding effect.

7. Fabric and film openers also makes materials feed smoothly and flatly.

8. For 4-way stretch fabrics, special fabric transmission belt can be installed on the laminating machine.

9. Impregnability of temperature after PUR,lasting elasticity,wear-resistance,oil resistance and anti oxidation.

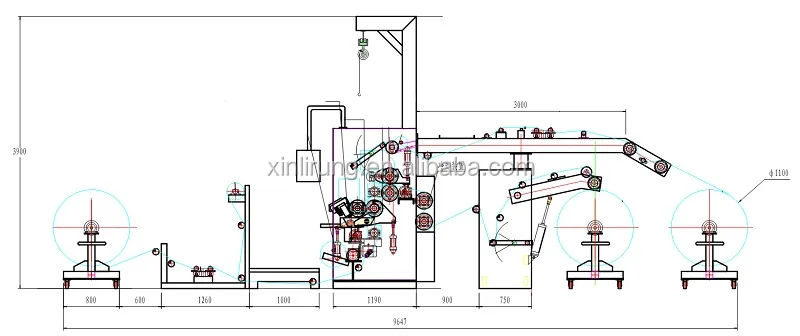

Main Technical parameters:

| Effective Fabrics Width | 1650~3200mm/Customized |

| Roller Width | 1800~3400mm/Customized |

| Production speed | 5-45 m/min |

| Demension (L*W*H) | 12000mm*2450mm*2200mm |

| Heating Method | heat conducting oil and electric |

| Voltage | 380V 50HZ 3Phase / customizable |

| Weight | about 6500kg |

| Gross Power | 40KW |

Mechanical mechanical drawing:

YouTube Video Link:

1) https://www.youtube.com/channel/UCpzcgdxSIATihZTNcJt7Ttw/videos?view_as=subscriber

Machine Details:

Похожие товары

GD-WSD недорогой двухцилиндровый полностью компьютеризированный простой вязальный станок для носков детские махровые носки машина производства

Оптовая продажа новая ручная кнопка значок пластиковая делая машину металлический

Многофункциональная машина для резки рулонов нетканого полотна YING

Полностью автоматическая заводская цена литой стакан N95 1860 форма лица Маска подвесная головка типа 1860s машина для изготовления

Профессиональный индивидуальный Высокоскоростной автоматический станок для ткацкого станка с узкими иглами поставщик из

Лучший продавец профессиональная вышивальная машина X PR1050X и комплекты обручей шляп

Недорогая автоматическая машина для фиксации люверсов с проушиной флага

Новые поступления

Новинки товаров от производителей по оптовым ценам