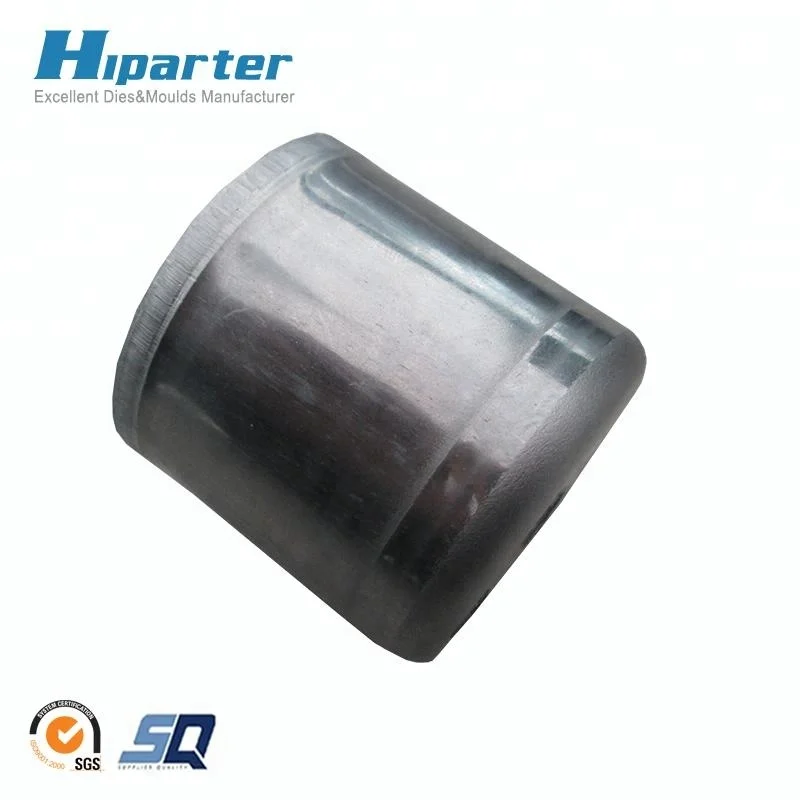

Metal Lamp Shade Deep Drawn Stamping Die Mould Mold Tool

- Категория: >>>

- Поставщик: Qingdao Hiparter Metal & Plastic Products Co. Ltd.Qingdao Ltd.

Сохранить в закладки 60779860141:

Описание и отзывы

Характеристики

Company Information

Qingdao Hiparter

More 18 years experience in plastic injection moulds,stage stamping dies, progressive dies and transfer dies etc.

1)Located in Qingdao,which is home appliance city with famous Haier, Hisense, Aucma;

2)Reasonable die structure to save cost, also guaranteethe quality of products;

3)Tracking every steps for manufacturing the dies, to ensure the lead time;

4)Feedback in 24 hours;

5)All employees intend to make each product with zero defect;

6)2~5 samples will be send to customers for inspection or assembly before shipping;

7)Advanced manufacturing, measuring and testing equipment.

3)Tracking every steps for manufacturing the dies, to ensure the lead time;

4)Feedback in 24 hours;

5)All employees intend to make each product with zero defect;

6)2~5 samples will be send to customers for inspection or assembly before shipping;

7)Advanced manufacturing, measuring and testing equipment.

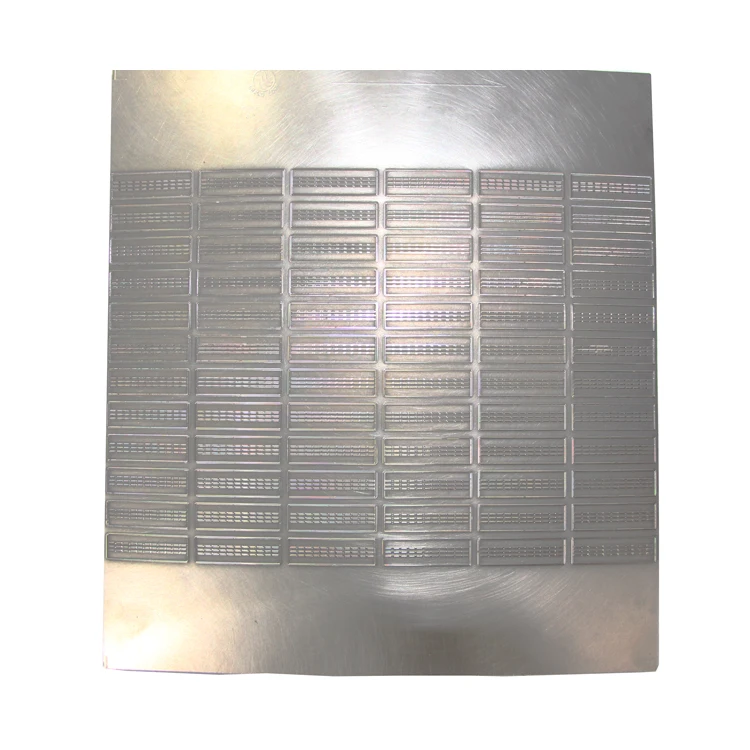

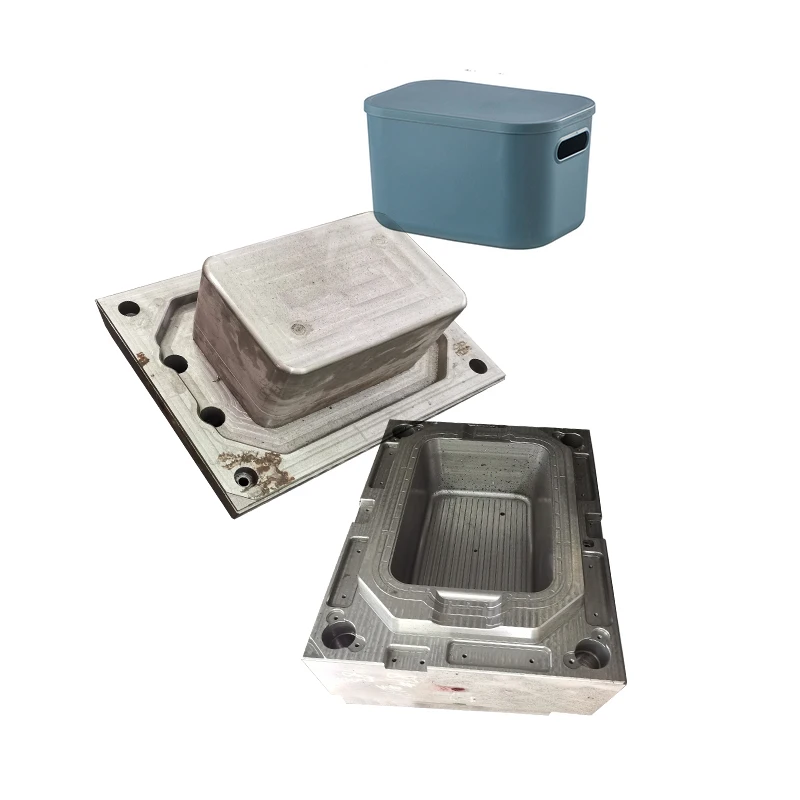

Products Description

Die Type | Stage Stamping Die, Progressive Stamping Die ,Transfer Stamping Die |

Die Material | AMPCO 25, SKH-9, DC53, SKD11, Cr12Mov, etc. |

Product Material | Steel, Tinplate, Nickel Silver, Spring steel, Stainless steel, Brass, Bronze, Phosphor Bronze, etc |

Standard Part | MISUMI, PUNCH, FIBRO, DAYTON, DME, etc. |

Die life | Over 1,000,000 shots |

Precision | +/-0.02mm |

Equipment | CNC machine,Automotic lathe machine,EDM machine,Wire-cutting machine,Milling/Grinding machine,Punching/Drilling machine,etc. |

Surface finish | Sand blasting, polishing, Electroplating, powder coating, oxidation ,Vacuum Plating |

Design software | CAE/CAXA/UG/PRO/E, Auto CAD, Slid Work |

Size/Color | Customer requirement |

Manufacturing Equipment

Workshop Display

Product photos

Related Products

Packing & Delivery

Packing

Packaging process fo each die before leave our factory

1.Painting: you can choose the colors accroding your requirements,such as black, green, yellow, blue......

2.Slushing oil: to protect the die surface avoid rust

3.PE film: keep the tool surface clean

4.Related documents: all the details for this die,such as structure drawing, instruction of operation, maintenance manual,

inspection report, factory checking list....

5.Outer packaging: Plywooden case, exported standard

6.Fastening: more stronger

2.Slushing oil: to protect the die surface avoid rust

3.PE film: keep the tool surface clean

4.Related documents: all the details for this die,such as structure drawing, instruction of operation, maintenance manual,

inspection report, factory checking list....

5.Outer packaging: Plywooden case, exported standard

6.Fastening: more stronger

Delivery

For trial samples delivery:

Express---DHL, FedEX,UPS, TNT, and so on

For die delivery:

Domestic--- by road, by air, or others

Overseas---by air, by sea

By air around 2-5 days. By sea around 15-40 days.

Usually we use wooden cases or plywood cases for the packaging. With rich experience in exporting, we can choose reasonable packaging for you to reduce the shipping risk. Of course you can appoint the packaging according to your requirement. We can try our best to satisfy you.

Express---DHL, FedEX,UPS, TNT, and so on

For die delivery:

Domestic--- by road, by air, or others

Overseas---by air, by sea

By air around 2-5 days. By sea around 15-40 days.

Usually we use wooden cases or plywood cases for the packaging. With rich experience in exporting, we can choose reasonable packaging for you to reduce the shipping risk. Of course you can appoint the packaging according to your requirement. We can try our best to satisfy you.

FAQ

1)Q: What information should be provide when you want get a quick quotation for progressive die?

A: Please kindly send us your 2D or 3D design drawing, product materials,the quantities that your will produce every month/year by this die casting molds/Molds.

2)Q: What design software do your engineers use?

2)Q: What design software do your engineers use?

A: Solidworks, PRO/E, UG, Autocad. Also we are able to work with Caita,Solidworks for format transition. .igs, .step, .x_t, .pdf, .dwg, .dxf files are okay for us.

3)Q: In general, what’s the lead time for the die casting molds?

A: In general, it will cost about 25-45 days to make the first die/Mold trial.

4)Q: Where is your company located in? Is the trafficconvenient?

A: Our company is located in Qingdao, north of China. Our factory is located near Jiaozhou International Airport and Qingdao Port, with a drive of less than an hour and convenient transportation.

Contact US

If you want to get more information about Hiparter or plastic injection mold ,please feel free to contact us as follows.we will feedback to you within 24 hours.

Похожие товары

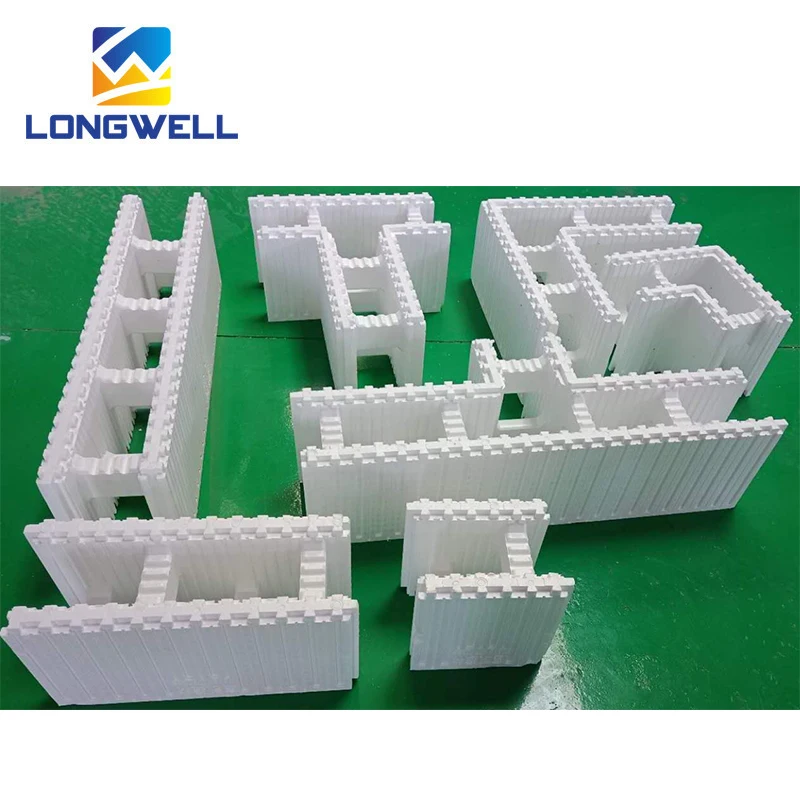

Дизайн пресс-формы для изготовления штамповочных инструментов из полистирола пластиковая литьевая форма литья под давлением OEM ODM Service

Custom tank Mould for Rotomolded Rain Water Storage

Высокоточная Пластиковая форма для литья под давлением

6 600,00 $

China Rotational Plastic Oil Fuel tank Mould CNC Machine Roto Mold Rotomolding Molds Aluminum Rotomoulded diesel

3 000,00-4 500,00 $

Пользовательские формы EPS ICF для инновационных строительных решений

16 000,00 $

Wireless Bt Headphones Mobile Phone Powebank Audifonos Earphone Tws Earbuds Plastic Parts Injection Molding Mold

0,20 $

Заводской заказной пластиковый прототип для инъекций ABS PP PC части смолы силиконовые формовочные услуги

50,00-160,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $