Новая технология камнедробилка лидер продаж в Азии шлифовальная машина мельница молотковая дробилка

- Категория: >>>

- Поставщик: Shanghai Yingyong Machinery Co. Ltd.Shanghai Ltd.

Сохранить в закладки 60785616510:

Описание и отзывы

Характеристики

Application Scope and Use of Coarse Grinding

1.) Application scope

Coarse grinding mill is mainly used in these areas, such as metallurgy, building, chemical, mining industriy, etc. It can grind a variety of non-explosive and non-flammable brittle mining materials, whose Moth's hardness is below 9 grade, such as quartz, feldspar, calcite, marble, porcelain, ironstone, copper ore, coal gangue, phosphate ore, granite, basalt, carborundum, corundum, heat insulating material and so on.

2.) Usage

Generating station to desulfidation: according to client's need, coarse grinding mill could be equipped with vibrating screen and could grind limestone into fine powder below 2mm or 1mm.

Quartz sand (silica sand, casting model powder, etc.): the fine sand from 0mm to 3mm can reach to 70% of the product.

Coarse powder mill: if it is used as coarse powder mill before ball mill, this machine can increase the efficiency of the ball mill by 50%.

Firebrick, baking-free brick, building blocks: the powder produced by this machine is the best mixture material for making baking-free brick and hollow building blocks.

Coarse powder: Equipped by vibrating screen, this machine's volume of production can be increased, 130-140% higher than normal Raymond mill.

Main Specification:

Model | PC4008-75 | PC4012-90 | PC4015-132 |

Diameter of the rotor(mm) rotor /mm | 750 | 900 | 1150 |

Length of the rotor(mm) | 800 | 1200 | 1500 |

Rotation speed of the rotor(r/min) | 800-1000 | 800-1000 | 550-800 |

Feeding opening(mm) | 320×930 | 400×1200 | 500×1500 |

Max. feeding size(mm) | <30 | <40 | <50 |

Max. output size(mm) | 0-3 | 0-3 | 0-8 |

Capacity (t/h) | 10-30 | 30-60 | 60-100 |

Motor Power(Kw) | 75 | 90 | 132 |

Dimension (L*W*H/mm) | 2310*1665*1610 | 2840*2100*2020 | 3720*2650*2540 |

2. Technical Features of Coarse Grinding

1.) It serves several purposes: this machine can produce the materials of various particle sizes after it constitutes the closed production line with auxiliary equipments.

2.) High efficiency: its efficiency of producing powder and fine sand is higher than ball mill, Raymond mill, vertical mill, etc.

3.) High operating factor of the abrasive materials: even wear of the plates avoids the trouble that rolls must be changed when the middle is sunken in the Raymond mill.

4.) Low fault rate: the special plate structure and seal make it more stable and longer service life than Raymond mill.

Note: All the technical data are subject to change without prior notice

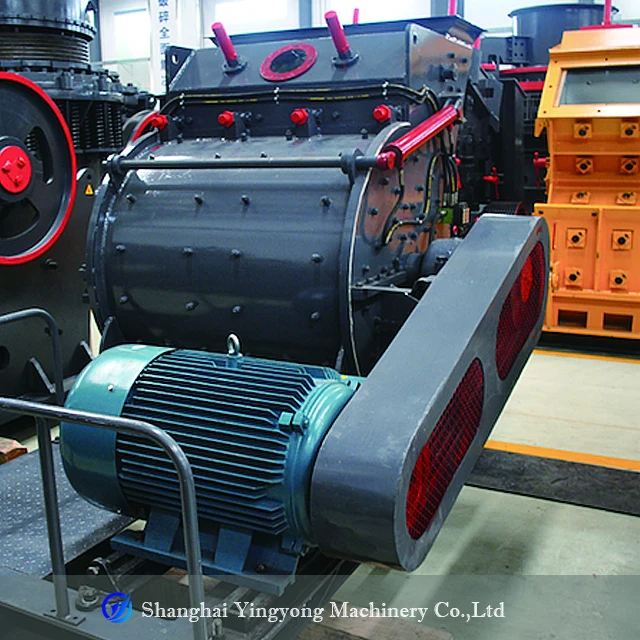

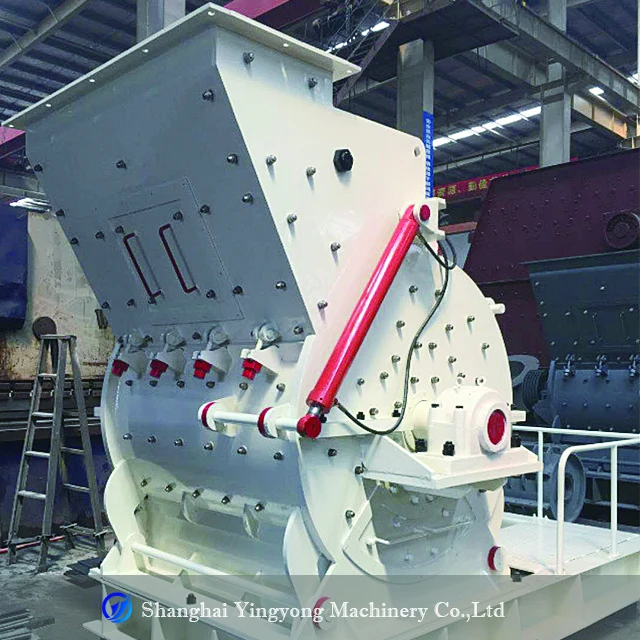

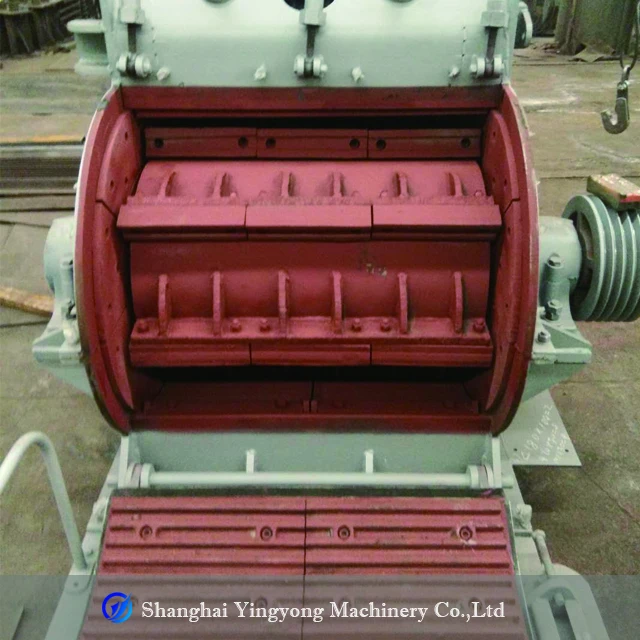

4. Main Structure and Working Principle

1).Coarse Grinding mill mainly consists of frame, rotor, impact plate, grizzly bars and other components. The frame includes upper part and lower part, which are welded by steel plates after cutting. The remaining parts are connected into an integrated one by bolts. Hard-wearing side plates are installed inside the frame. It is easy to replace them when they are worn. On the main shaft are installed several groups of the blow bars with even weight, which are fixed tightly by high-strength bolt.

2).The host drives the main shaft through the electric motor and V-belt, thereby making the rotor rotate. The bulks of material fed into the crushing chamber will be crushed by the hammers at a high-speed movement. The qualified broken material will be passed the grizzly bars at the lower part

Q: Hi, are you mining machinery manufacturer?

A: Yes, our company warmly welcome clients to visit our plant at any time. We can also provide samples test, mine design, equipment manufacture, after-sale service, etc...

Q: Which country have your products been exported?

A: We have been exported business for 10 years and we have lots of customers and agents in the world, such as Middle East, Malaysia, South Africa, Canada, America, etc…

Q: What information should customers give us, so that we can be able to provide you suitable quotation and service.

A: What minerals to be processed?

What's the feeding size of your raw minerals? And the moisture?

What is the capacity do you need per hour for your project?

What are your requirements for your end products?

Q: How long is the warranty of your equipment? Does your company supply the spare parts?

A: The usual warranty period is one year. And of course, we will supply the spare parts for you at lowest cost.

Q: If I need the complete mineral processing line, can you help us to build it?

A: Yes, we can help you combine a complete mineral processing line and give you related professional advices as long as you need. We had already build many mining projects in China & Overseas. We can set a complete processing line just as you require.

Ways of Packing

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

Shanghai YINGYONG Machinery Co., Ltd was found in 1986, formerly known as Shanghai Mining Machinery Factory. After 30 years of experiences, we become one of the most important machinery manufacturing company in China and is member of China Heavy Machinery Industry Association (CHMIA).

Our company occupies 128 thousand m2, with RMB 250 million of total assets, about 500 employees, more than 300 senior engineers and high-quality workers. We are equipped with more than 200 sets heavy equipments for large and medium finishing machining, rivet welding, heat treatment and assembly etc. Keeping development and technic innovation, we have formed a complete production line from casting, welding, heat treatment to riveting, equipments machining, assembly and testing with perfect general production capacity.

Our main products: crusher, sand making machine, feeder, rotary kiln, dryer, medium speed coal grinding mill, vertical mill, ball mill etc. are widely used in mining materials treatment, cement and construction materials production, thermal power stations, chemical industry, fertilizer production, metallurgy and environment production etc. Our machines have served customers all over China and have been exported to more than 60 countries and areas, and are widely acclaimed both domestically and aboard.

YINGYONG is able to produce large piece or manufacture according to requirements: rotary kiln up to φ6m, grinding mill up to φ5×16m, our bending machine could bend up to φ6m and thickness 120mm, casting piece could be up to 24t net weight, equipments could treat all kinds of pieces up to φ8m and 80t weight, hobbing machine up to φ8m.

Похожие товары

Лучшая мини-каменная дробилка Высокого Качества Щековая прайс-лист

Профессиональная машина для производства песка ударная Дробилка камнедробилка цена

1000 Тип Двойной Валик дробилка гусиное яйцо камень Дробление и песок оборудование

Лидер продаж простой в эксплуатации двигатель или дизельный деревянная ветка для садового строительства

Китайский производитель XHP многоцилиндровая конусная дробилка для продажи

Китай заводская цена низкая стоимость добыча золота руды молотковые дробилки

Китайская профессиональная конусная дробилка с пружиной от производителя конвейерная электросхемой управления

Новые поступления

Новинки товаров от производителей по оптовым ценам