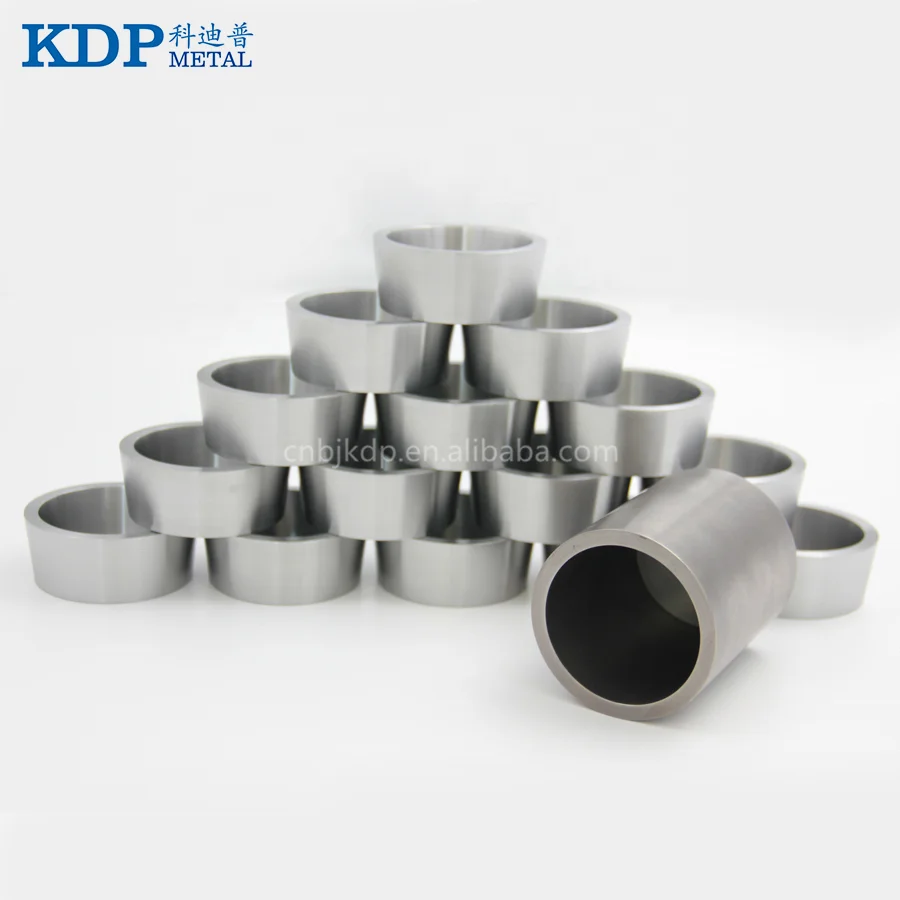

Тигель из чистого титанового металлического сплава Tc20

- Категория: Tungsten Crucibles >>>

- Поставщик: Baoji Kedipu New Material Co. Ltd.

Сохранить в закладки 60786720773:

Описание и отзывы

Характеристики

pure Titanium Metal Alloy Tc20 Melting Pot Crucible

Dimension and tolerance

Delivery condition | Specification | Tolerance |

Thickness |

Roughness (um) | ||

Diameter | Height | Diameter | Height | |||

Sintering | 10~500 | 10~750 | +/-5.0 | +/-5.0 | 8~20 | <3.5 |

Sintering finishing |

10~450 |

10~550 |

+/-0.5 |

+/-0.5 |

7~18 |

<2.5 |

Special sizes can be manufactured according to customers' requirements.

1. For producing electric light source parts and electric vacuum components. 2. For producing heating elements and refractory parts in high temperature furnaces. 3. For producing medical laboratory equipment. 4. Used as electrodes in the field of rare earth equipment. 5. Uesd in the manufacture of weapons. 6. Uesd for the thermalcouple protection tube in the high temperature furnace. |

Our Wealth

| 1. 2001, we've been providing high-quality products & service for over 15 consecutive years. 2. The factory covers an area of 25,000 square meter. 3. We have over 80 employees, including a group of experts in non-ferrous industry. 4. We have a professional team foreign trade. |

A Glimpse of Our Equipment

| We are equipped with advanced machines: 5 sets of intermediate frequency sintering furnace, 1 set of cold iso-static pressing machine (1000*3000mm), 6 sets of hot & cold rolling machines (450-1000mm), 1 set of large-scale rolling machine (1300mm), 1 set of large-scale grinding machine (600*3000mm), 1 set of large-scale water cutting machine (3000*6000mm), 1 set of large-scale laser cutting machine (2000*4000mm), 18 sets of wire cutting machine (1200*1600mm) and another tens of drilling, turning, milling, cutting and grinding machines. |

Our Certificates

1. We are an ISO9001 certified company. 2. We've been granted the patent in making Molybdenum&Niobium alloy. 3. We've been awarded as a High-Tech Enterprise. 4. We've been invested by the National Fund for High-end Equipment.

|

We welcome dear customers from all around the world with OEM&ODM service.

Powder Metallurgy

6 workshops: powder molding workshop, forging workshop, rolling workshop, vacuum furnace manufacturing workshop, machining workshop and cutting workshop, and 1 inspection center. |

Vacuum Induction Smelting

We can also make metal products through vacuum induction smelting process, for instance nickel and its alloys. Combining with other equipment like forging machine, rolling machine etc, we can also make Nickel N4 & N6 plate, sheet, foil, strip etc. |

| TNT, EMS, UPS, FedEx, DHL, air transport, sea transport and railway transport are available. We will try our best to choose the most proper method to satisfy our customer's demands. Every order will be tracked until our product are well received. |

Payment Terms

1. <USD 5,000, 100% by T/T. 2. USD 5,000- USD 20,000, 30% advance payment, balance payment is negotiable. 3. L/C, Western union, Moneygram and Paypal are also available. |

| Please don't hesitate to contact us for any question. Each and everyone of our team would be glad to be at your service. |

Похожие товары

Лодка из чистого вольфрама для испарения

Танталовые вольфрамовые ниобиевые молибденовые тигли для испарительного сосуда

Высокочистый кованый вольфрамовый тигель для плавления

Высокотемпературный вольфрамовый тигель для плавки

Безупречные детские носки высокого качества, evopration вольфрама вкладыши вольфрамовые тигли для плавления/выращивания сапфиров

SML Molybdenum Tungsten Melting Crucible Pot for Industry Use

Вольфрамовый тигель, вольфрамовый тигель

Новые поступления

Новинки товаров от производителей по оптовым ценам