hdpe geomembrane liner hot wedge welder welding machine

- Категория: >>>

- Поставщик: Dongguan Jingyi High Frequency Machinery Co. Ltd.

Сохранить в закладки 60787065991:

Описание и отзывы

Характеристики

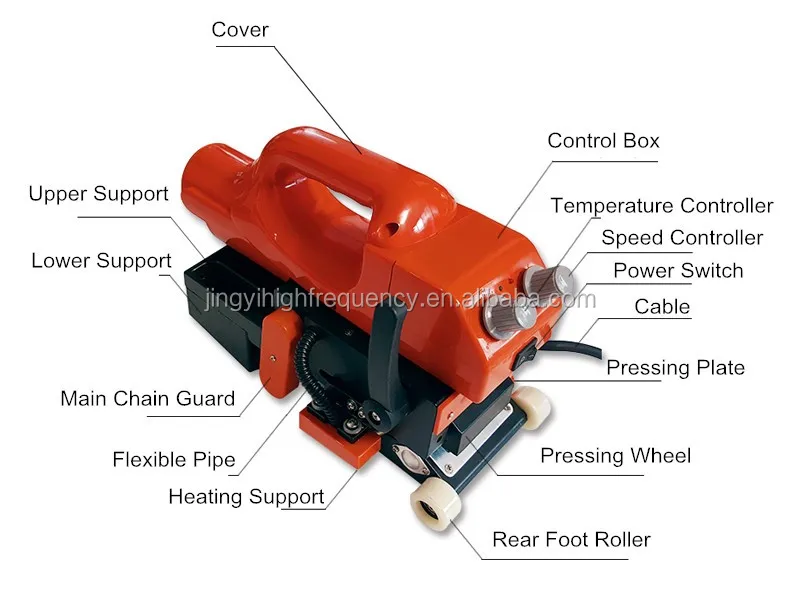

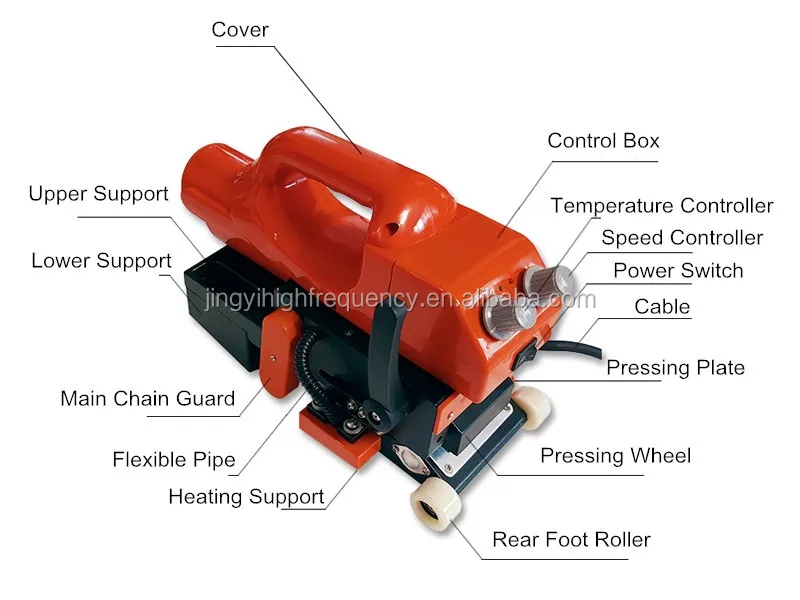

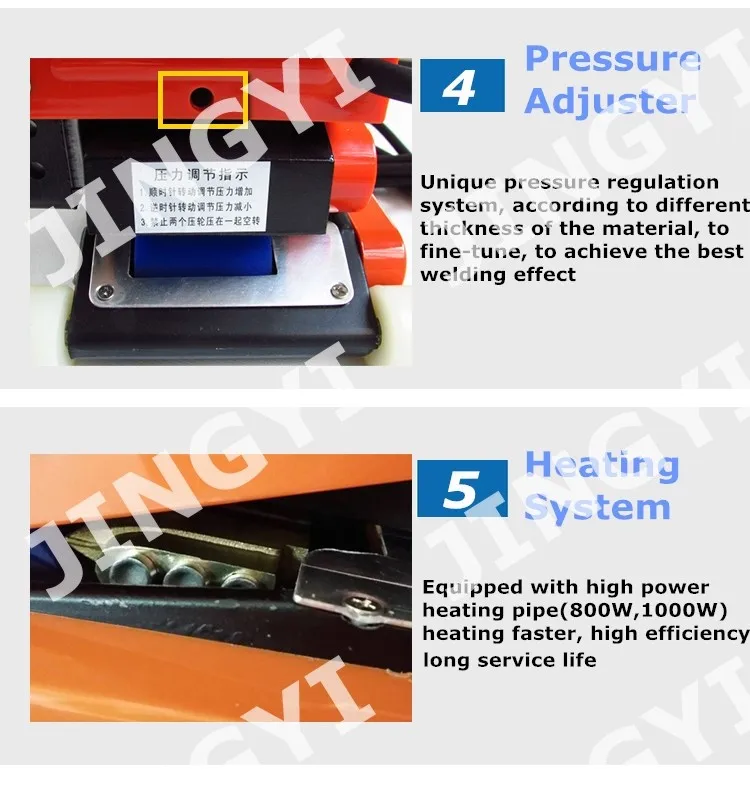

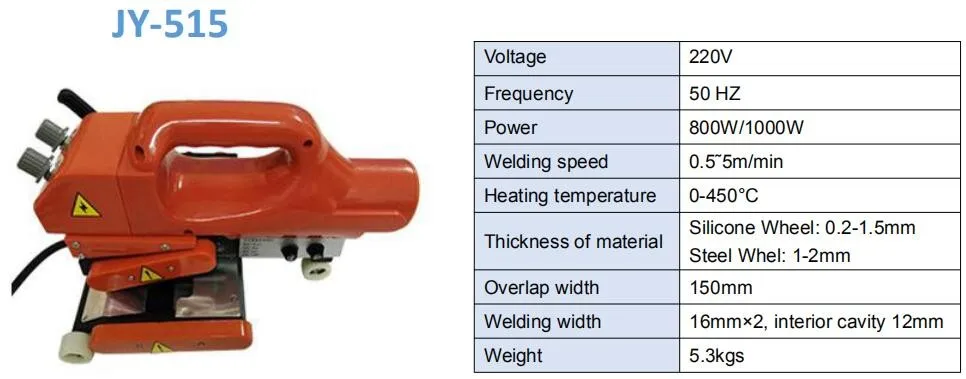

Machine Introduction:

Geomembrane welding machine is our new developed products, which can weld geomembrane of different thickness and are applicable for welding of all thermal-fused material such as PE, PVC, HDPE, EVA, PP and the like.

The control of this series of welding machine adopts PID automatic thermostatic control with high control accuracy and low temperature fluctuation; speed control adopts PWM automatic voltage and speed regulation circuit, driven by DC servo motor, with great output torque and the operating is stable. It can maintain a constant speed on the condition of creeping, vertical creeping and variable road load. Also this series of welding machine is stable in performance despite of external temperature and voltage variation.

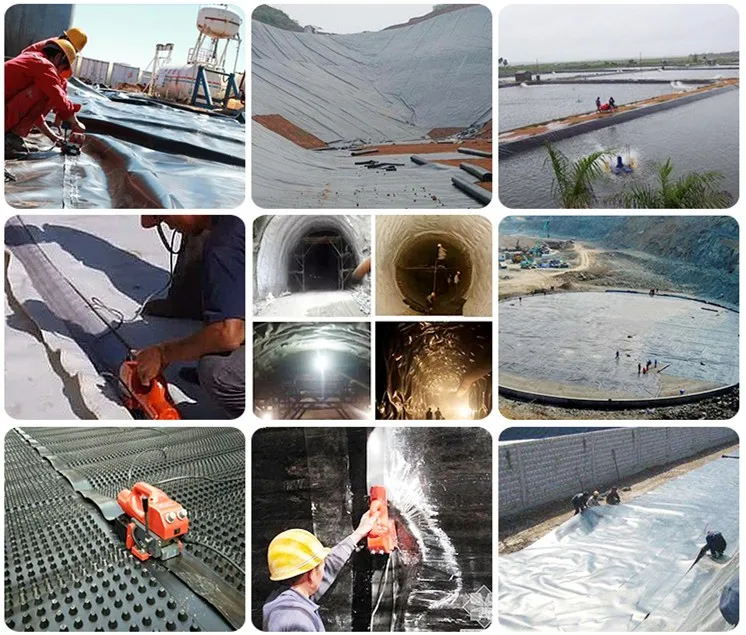

This series of welding machine is excellent in performance and easy for operating, with high welding speed and good work quality. It is extensively used inengineering projects such as express highways, tunnels, reservoirs, waterproof of construction and so on.

For material such as LDPE, PVC, HDPE, EVA, PP and PVC,HDPE,EVA,PP

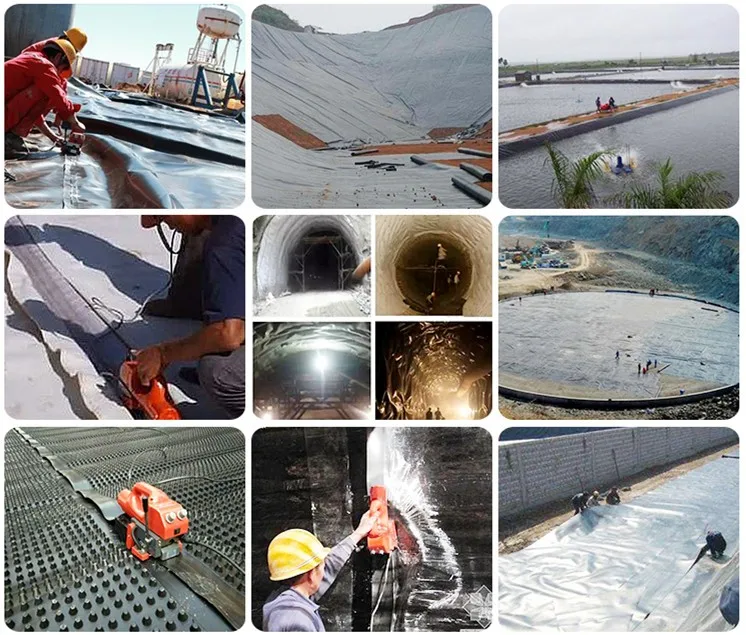

Application covers refuse landfill anti-seepage project, sewage disposal anti-seepage project,lake anti-seepage project, water conservancy anti-seepage project, tunnel anti-seepage project,minerals place anti-seepage project, cultivation pond anti-seepage project, roofing waterproofing project etc.

As welding quality is direct related to speed and temperature setting during operating, so welding machine must be specified personnel operated to reach excellent quality and high efficiency.

1). Use with grounded 3-cord mains cable and 3-hole socket with capacity not less than 10A (socket corresponds with welder plug, phase L connected to live wire, N to zero line, phase = to grounded protection line), confirm that external lines have been well connected. Check that power is on off state and regulate temperature control potentiometer and speed control potentiometer to 0 position, press lever handle down to disengage pressure roller, then insert the plug.

2). Turn on the power and select certain temperature and speed, take several narrow materials for try welding. Temperature selection may be different for the same material at different ambient temperature and material thickness. To determine the best welding effect, adjust the speed to approximately 2m/min, and then fine increase it from low to high temperature (approximately 250-350 degree)

3). Judge on welding temperature: for transparent PE material, judge by direct observing, speed and temperature will be appropriate if welding mark is flat and in transparent glass form; temperature will be too high and speed be too slow if mark is heavy broken; temperature will be low and speed be fast if mark is not transparent and with white. For opaque material, observe if there is obvious welding mark, also tensile test can be made after complete cooling.

4). Flatly and straightly trim the weld edges and frontage faced, with lower left and upper right overlapped. The overlap width is 100mm.

5). After temperature and speed have been determined, insert material to be welded between the two pressure rollers, make machine body parallel with edges of base materials and engage press lever handle for proper motion. Generally, only observation of deviation between welding mark and base materials is needed for operator, and timely make correction on small degree.

6). When welding will be ended, timely press lever handle to disengage upper and lower pressure roller to prevent rubber wheel damage for long duration.

7). Excessive temperature high and low may occur because of thermal inertia. On this condition, temperature deviation may be compensated by speed regulation on a small degree.

8). A "T"shape overlap is formed between welded material and another material. Welding method is shown as fig.5, tightly butt the overlap head of hot wedge against weld mark, and beveling cut length is approximately 100mm.

Packing:

Machine packing inside is plastic films and outside is Strong

packing box

The machine will be equipped with one set spare part.

Delivery:

This machine is not heavy and big, we suggest you to ship

it by couriers.

The price show on our website just the machine EXW price, please contact us before you place order.

Dongguan Jing Yi High Frequency Machinery Co., Ltd. has been committed to R&D, production and sales of the plastic welding field ever since its establishment in 1991.

We are professional designer and manufacturer of Geomenbrane welding machine, High Frequency Welding Machine, Ultrasonic Plastic Welding Machine, Heat Press & Cold Mould Machine, Blister Packing Mahcine and other Packing Machine with over 25 years.

We welcome both new and regular customers at home and abroad to visit us and cooperate with us to achieve mutual profits and create a better future. We are convinced that your partnership with us can help your business scale a new high.

The sea admits hundreds of rivers for its capacity to hold. Since its inception, JINGYI always pay attention to the cooperation with famous enterprises both at home and abroad; By the network, optimize enterprise resources and integrate industry technology, constantly temper the team to build an elite team and provide high quality product.

Q: Are you trading company or manufacturer ?

A:Yes, We are factory, all machine is made by ourself and we can provide customize service according to your requirement.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q:What about your warranty?

A:Our warranty is 1 year, all machine part can be replaced for free within 1year if broken(not including man made).

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Beverage bottle, cosmetic bottle, medicine bottle, jar etc.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Pre-sale services:

1. Providing professional technical support.

2. Send the product catalog and instruction manual.

3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!

4. Personal call or visit are warmly welcome.

Sale of services:

1. We promise honest and fair, it's our pleasure to serve you as your purchasing consultant.

2. We guarantee punctuality, quality and quantities strictly implement the terms of contract.

After-sales service:

1. Where to buy our products for 1 years warranty and life long maintenance.

2. 24-hours telephone service.

3. A large stock of components and parts, easily-worn parts.

Please call us now if you are interested in our products!!!

Похожие товары

Заводская прямая машина для сварки листового полиэтилена геомембраны

Alibaba кромкооблицовочная машина, покупка онлайн для столярной промышленности

Стиль 10, активный коленчатый или Поворотный шарнир и соединение Chiksan

Авиаперевозчик из Китая в США/Великобританию/Германию/Европу/Канаду/Японию Amazon DDP от двери до двери

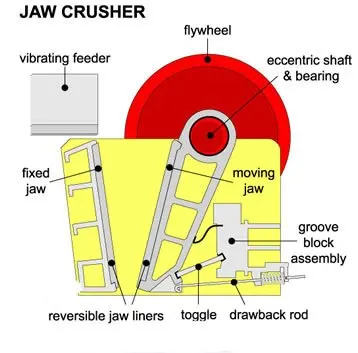

Щековая Дробилка Серии PE / PEX для шоссе/железной дороги/строительного материала

Дисковый тормоз для горного велосипеда, 26 дюймов

Alibaba продукты pet tag гравировальный станок купить оптом напрямую из китая

Новые поступления

Новинки товаров от производителей по оптовым ценам