Китай дешевая машина для измельчения известняка серия MTM средняя скорость трапециевидная мельница порошок измельчитель Raymond цена распродажа

- Категория: >>>

- Поставщик: Shanghai Yingyong Machinery Co. Ltd.Shanghai Ltd.

Сохранить в закладки 60789220763:

Описание и отзывы

Характеристики

Product Application

MTM Powder Grinding Mill is the based on years of research and development of industrial mill on the introduction of a world-class industrial milling technology, organize a large number of technical experts and related projects designed to test and improve the development of the world's leading industrial mill. The machine uses a trapezoidal Face, flexible connection, roll linked supercharged mill and many other national patent technology, completely overcome the terms scope, yield, fineness, energy, life and other traditional industrial milling machines the defect is Raymond, high pressure suspension mill, ball mill and other traditional mill ideal alternative. At present, the model has been widely used in China's metallurgical, power, chemicals, iron and steel, building materials, coal and other industries, resulting in huge economic benefits.

MTM Medium Speed Trapezium grinder is a kind of leading-world-level industrial milling machinery. It is designed by our own engineers and technical workers, basing on industrial mill research of many years and adopting world-leading-powder processing technology. Now a number of customers are fond of it for its incomparable features.

Technical data --price mill min

Name | MTM100 | MTM130 | MTM160 |

Ring roll number(pcs) | 4 | 5 | 6 |

Major diameter of roller(mm) | Φ310X170 | Φ410X210 | Φ440X270 |

Inner diameter of roller(mm) | Φ950X170 | Φ1280X210 | Φ1600X270 |

Revolving Speed(rmin) | 130 | 103 | 82 |

Max feed size(mm) | <25 | <30 | <35 |

1.6-0.045 fineness can reach to 0.038 | 1.6-0.045 fineness can reach to 0.038 | 1.6-0.045 fineness can reach to 0.038 | |

Output(th) | 3-8 | 6-11 | 9-22 |

Complete physical size(mm) | 7100×5900×7900 | 7100×5900×7900 | 12550×5700×8355 |

Model | Y225S-4 | Y280S-4 | |

Power(kw) | 37 | 75 | |

Rotate speed(rmin) | 1480 | 1480 | |

Model | Y225S-4 | Y280S-4 | |

Power(kw) | 37 | 75 | |

Rotate speed(rmin) | 1480 | 1480 | |

Model | YCT200-4A | YCT200-4B | |

Power(kw) | 5.5 | 7.5 | |

Rotate speed(rmin) | 125-1250 | 125-1250 | |

Elevator | Elevator model | TH210 | TH210 |

Motor model | Y100L2-4 | Y100L2-4 | |

Power(kw) | 3 | 3 | |

Rotate speed(rmin) | 1430 | 1430 | |

Jaw Crusher Model | PE200×350 | PE250×400 | |

Main unit motor | Y160M-6 | Y180L-6 | |

Power(kw) | 7.5 | 15 | |

Rotate speed(rmin) | 970 | 970 | |

Main unit motor | GZ2F | GZ3F | |

Power(kw) | 0.15 | 0.2 |

Grinding mill working process

In the grinding mill,Air is driven into the undersurface of the grinding ring and flows upward, carrying fines to the classifying section. The classifier allowed the pulverized material to pass and the oversized particles are drove back to the grinding chamber for further processing. The whole mill operates under negative pressure conditions, which can maximize the service life of span>major mechanica components. Thus minimizing mill maintenance and plant housekeeping problems have been solved.

Grinding material product --price mill mini

feed particle size: 25-35mm

Outlet size: 1.6-0.045 fineness can reach to 0.038

production capacity: 3-22T/h

Applicable material:

Grinding Mohs hardness below 9.3 and humidity below 6% of all non inflammable and explosive mineral materials, such as cement raw material and clinker), coal, talc, feldspar, quartz, iron ore, mica, calcite, limestone, barite, potassium sulfate, bentonite, over a thousand kinds of material.

classic case- --price mill mini

MTM100 grinding production line

Finished product for steel desulfurization, and Baosteel, Masteel, long-term cooperation, more than ten years of industry experience; has from our purchased three sets of YGM9517 suspended roller mill, 2 sets of MTM100 speed trapezium mill, and our cooperation up to 12 years.

Production situation

Daily operation: 22-24 hours

Feed: to the main lime, auxiliary materials for limestone, fluorite

Product: 300 mesh, the powder selection machine speed is 320~350r/min, 90% pass sieve rate

Ways of Packing:

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

ABOUT US

Shanghai YINGYONG Machinery Co., Ltd was found in 1986, formerly known as Shanghai Mining Machinery Factory. After 30 years of experiences, we become one of the most important machinery manufacturing company in China and is member of China Heavy Machinery Industry Association (CHMIA).

Our company occupies 128 thousand m2, with RMB 250 million of total assets, about 500 employees, more than 300 senior engineers and high-quality workers. We are equipped with more than 200 sets heavy equipments for large and medium finishing machining, rivet welding, heat treatment and assembly etc. Keeping development and technic innovation, we have formed a complete production line from casting, welding, heat treatment to riveting, equipments machining, assembly and testing with perfect general production capacity.

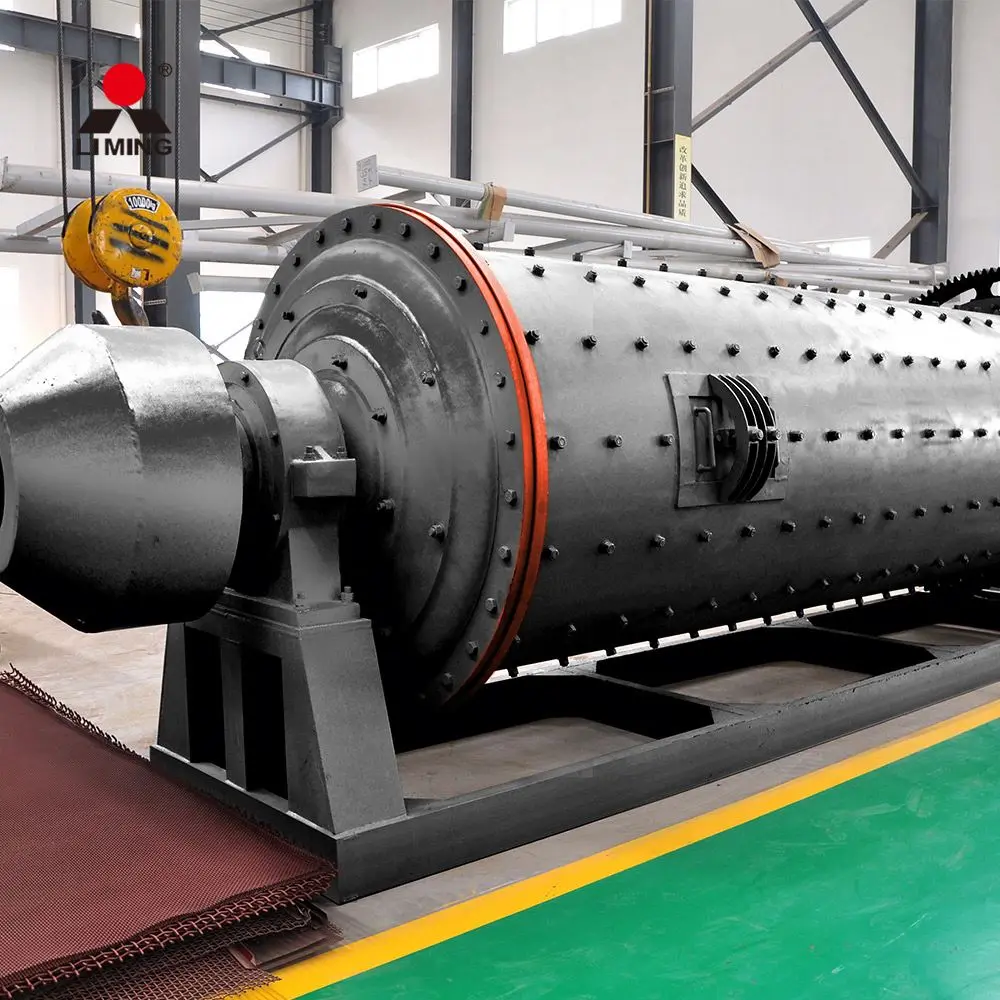

Our main products: crusher, sand making machine, feeder, rotary kiln, dryer, medium speed coal grinding mill, vertical mill, ball mill etc. are widely used in mining materials treatment, cement and construction materials production, thermal power stations, chemical industry, fertilizer production, metallurgy and environment production etc. Our machines have served customers all over China and have been exported to more than 60 countries and areas, and are widely acclaimed both domestically and aboard.

YINGYONG is able to produce large piece or manufacture according to requirements: rotary kiln up to 6m, grinding mill up to 5*16m, our bending machine could bend up to 6m and thickness 120mm, casting piece could be up to 24t net weight, equipments could treat all kinds of pieces up to 8m and 80t weight, hobbing machine up to 8m.

Q: Hi, are you mining machinery manufacturer?

A: Yes, our company warmly welcome clients to visit our plant at any time. We can also provide samples test, mine design, equipment manufacture, after-sale service, etc...

Q: Which country have your products been exported?

A: We have been exported business for 10 years and we have lots of customers and agents in the world, such as Middle East, Malaysia, South Africa, Canada, America, etc...

Q: What information should customers give us, so that we can be able to provide you suitable quotation and service.

A: What minerals to be processed?

What's the feeding size of your raw minerals? And the moisture?

What is the capacity do you need per hour for your project?

What are your requirements for your end products?

Q: How long is the warranty of your equipment? Does your company supply the spare parts?

A: The usual warranty period is one year. And of course, we will supply the spare parts for you at lowest cost.

Q: If I need the complete mineral processing line, can you help us to build it?

A: Yes, we can help you combine a complete mineral processing line and give you related professional advices as long as you need. We had already build many mining projects in China & Overseas. We can set a complete processing line just as you require.

Похожие товары

Кварцевый порошок шаровой мельницы шлифования и классификации производственной линии

10 болтов шаровая мельница 900*3000 Высокая марганцевая подкладка 13% вкладыш

Шаровая мельница 100tph керамическая глазурованная шаровая с глиноземной подкладкой

Шаровая мельница с хорошей производительностью по более низкой цене

Резиновая облицованная шаровая мельница 1800x4000

Шаровая мельница трубчатая

Заводская поставка Золотая Руда

Новые поступления

Новинки товаров от производителей по оптовым ценам