Высокочастотная сварочная алюминиевая трубчатая мельница радиатора

- Категория: Pipe Making Machinery >>>

- Поставщик: Nantong Zhenhuan Trade Co. Ltd.

Сохранить в закладки 60793213634:

Описание и отзывы

Характеристики

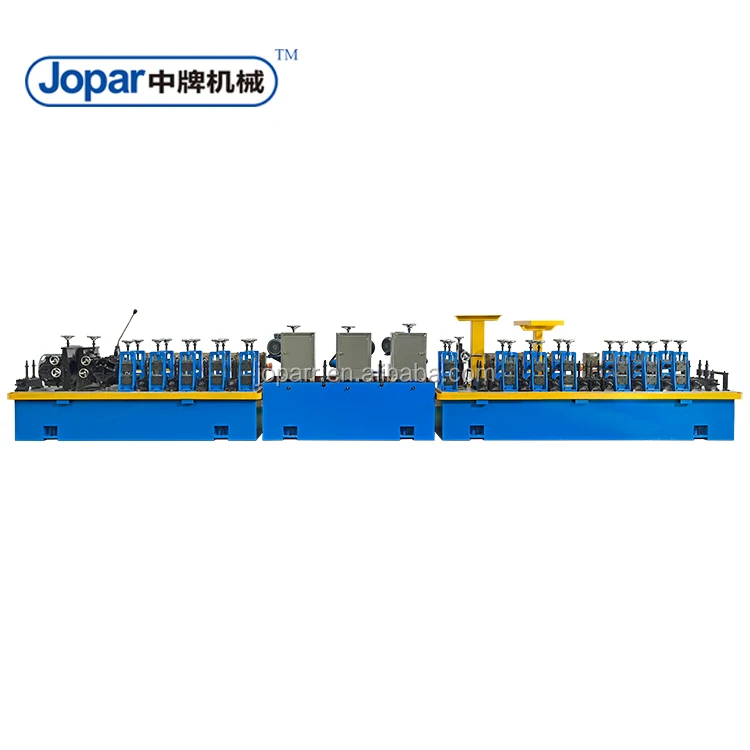

High Frequency Welding Aluminum Radiator Tube Mill

I Description of high frequency welding aluminum radiator tube mill:

This machine is specially designed for producing flat aluminum tubes & header pipes used in automobile radiators, round & rectangular aluminum pipes and other special shape aluminum pipes.

|high frequency aluminum tube welding machine|high frequency aluminum pipe welding machine|

This high frequency aluminum tube welding machine can 100% replace those aluminum pipe welding machines from Schoeler Germany, Millmaster USA or Japan.

Production flow of this high frequency aluminum tube welding machine:

- Aluminum strip reel loading by vacuum absorber loading device (optional)

- Aluminum strip decoiling by active decoiler

- Aluminum strip feeding by synchronization feeder with buffer

- Pre-forming by pre-forming mould section

- Welding by solid-state high-frequency welder

- Squeezing by ceramic rollers

- Burr removing

- Size fixing by size-fixing mould section

|high frequency aluminum tube welding machine|high frequency aluminum pipe welding machine|

II Main Features of high frequency welding aluminum radiator tube mill:

- Adopting special dry-type forming & welding technology, avoiding secondary pollution and corrosion to raw material.

- Special roller designing and adjusting technology for various aluminum pipe forming.

- Full servo drive, stable working and high precision

- Max. production speed 100m/min

- High quality solid state high-frequency welder, less electric consumption, smaller internal burr

- Online cut-to-length, no need secondary processing

- Mould material adopts precision smelting technology, processed by high precision CNC machine center from Japan, surface roughness 0.0004mm; Perfect mould size thermal stability, kept within ±0.002mm.

- Super high cutting speed:

160~200 cuts/min @750mm length

300~375 cuts/min @400mm length

120~150 cuts/min @1000mm length

40~50 cuts/min @3000mm length

20~25 cuts/min @6000mm length

- Quick roller changing design:

|high frequency aluminum tube welding machine|high frequency aluminum pipe welding machine|

III Main technical data of high frequency welding aluminum radiator tube mill:

Item | Data |

Suitable material | Pure aluminum or aluminum alloy 4343/3003/7072 or 4343/3005/7072 |

Applicable flat aluminum pipe size | 16~32mm x 1.5~3.0mm x 0.28~0.32mm |

Applicable rectangular aluminum pipe size | 50~90mm x 8mm x 0.32~0.6mm |

Applicable round aluminum pipe size | diameter 8-32mm |

Suitable aluminum pipe length | 300~8000mm |

Production speed | Max. 100m/min |

Cooling method for welder | Soft water circulation + air cooler |

Cooling method for rollers | Special volatile oil coolant (dry-type) |

Straightness of finished pipe | ≤1mm @1000mm length |

Cutting end inclination | ≤0.3mm |

Cutting burr height | ≤0.08mm |

Cut-to-length precision | ≤ ±0.3mm |

Straightening precision in width direction | ≤0.5 / 800mm |

Straightening precision in thickness direction | ≤0.8 / 800mm |

Duration for changing rollers | 2~4 hours |

High-frequency power | 100kVA |

Total electric power | About 150kVA |

Total electric consumption | About 30 kW·h |

Air source | 0.5-0.7MPa, 2m3/min |

Noise level | ≤78dB (@2m away) |

Pollution | Welding smoke & dust collecting, no liquid pollution discharged |

Total weight | About15 Tons |

Whole line dimension | About 26m x 4.5m x 3.5m |

|high frequency aluminum tube welding machine|high frequency aluminum pipe welding machine|

Cut-to-length precision of aluminum radiator tube mill:

Optional aluminum strip reel loading device for aluminum radiator tube mill:

|high frequency aluminum tube welding machine|high frequency aluminum pipe welding machine|

Our Nantong Zhenhuan Trade Co., Ltd., established in 2004, is specialized in various machines for different industries. We can provide you best solution, not only good quality machines, but also good services. We are certified by TUV, BV and SGS for good credit and reputation.

|high frequency aluminum tube welding machine|high frequency aluminum pipe welding machine||high frequency aluminum tube welding machine|high frequency aluminum pipe welding machine|

Please contact with Mr. Franks Cao for more machine details:

Skype: frankscao

Whatsapp: +86-13962724758

Похожие товары

Прямая поставка от производителя стальная оцинкованная ленточная катушка машина для плоских труб предварительно напряженная мостовая гофрированная труба

Машина для формовки желоба машина горячая Распродажа круглых пустотелых желобов с полимерным

Предварительно напряжённый железобетон цилиндрическая труба PCCP трубы весь производственный

Jopar трубная мельница из нержавеющей стали, производственная линия труб из нержавеющей стали

380 В Внутренний замок оцинкованная сталь жидкая плотная металлическая формовочная гибкая труба машина для изготовления труб

Электрическая машина для изготовления бетонных столбов электростолб

Качественные производители дренажных труб стальные формы для

Новые поступления

Новинки товаров от производителей по оптовым ценам