Лидер продаж горелка на биомассе цена промышленная деревянная

- Категория: >>>

- Поставщик: Henan Swet Boiler Co. Ltd.

Сохранить в закладки 60794150330:

Описание и отзывы

Характеристики

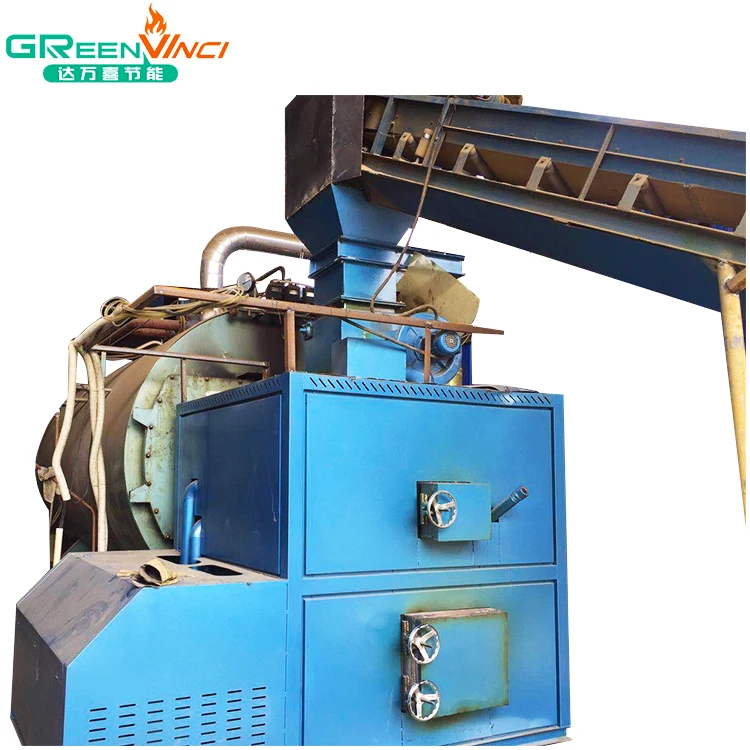

Best selling biomass pellet burner price industrial wood burner

1.Explanation of major components and terms:

(1)Hopper: used to store biomass pellets.

(2)Main body of vaporization chamber: biomass particle fuel gasification in gasification chamber

(3)Fire mouth (fire mouth): divided into inner tube and outer tube, the inner tube emits combustion gas.

(4)Grate: The middle position of the door of the vaporization chamber, used for air distribution when the particles are burned and vaporized.

(5)Ash door: The burner must open the door every 2-8 hours of work to clean the ash on the grate. When opening the door, be sure to stop the blower for more than 10 minutes and stand on the side of the door and keep it for more than 2 meters. The safe distance, after the blower stops running, open with a long iron. There is no flame and the combustible gas can be ejected before the door can be cleaned.

(6)Blower: Distribution of air for combustion and gasification.

(7)Wind box: used to adjust the air volume and air pressure.

(8)Bottom wind: From the bottom of the grate.

(9)Secondary air: Mezzanine distribution between the inner and outer tubes of the fire vent, and the secondary combustion of combustible gas in the combustion flaring.

(10)Feeding motor: screw rod used to drive feeding system.

(11)Feeding system: Feed biomass pellets into the combustion chamber.

(12)Casters: For short-distance movement of the burner (use a forklift away from the distance to avoid damage to the rigid vibrating refractory layer).

(13)Fuel: Pure woody biomass pellet fuel, diameter 8-10MM, length less than 30mm, heating value above 3500KCal, ash content less than 3% (large tonnage burner can burn 30MM biomass briquette fuel).

2.Conditions of Use

1. The biomass burning machine needs to work under negative pressure. At the same time, the ID fan must be installed to ensure the negative pressure. If it is applied to aluminum melting furnace, greenhouse heating, drying room and other working conditions, it can be operated at slightly positive pressure. However, it is necessary to ensure the smooth flow of the flue; the cross-sectional area of the exhaust outlet and the power of the induced draft fan will be carried out according to the requirements specified by the engineering department of our company.

2. The use environment of biomass burning machine must be well ventilated, and there are enough installation positions and operating positions. There must be no obstructions in the direction of the furnace door to affect the cleaning operation, and the distance from the wall should be at least 1.5 times the diameter of the furnace.

3. When using the burner, two 2KG dry powder fire extinguishers must be equipped within 5 meters of the burner.

4. must be equipped with a special operator to operate, the operator must be guided by the machine can operate the machine.

5.If the product is used in a boiler, it should be submitted to a qualified boiler installation company for installation. If there is a size deviation due to the size of the burner mouthpiece, the size of the boiler's crater must be corrected. The product must be reported to the local boiler inspection office for approval. Qualified boiler maintenance unit.

1.Henan Swet Boiler Co.Ltd was established in 1954 ,We have continued to provide customers with more than 60 years of quality service, known as the king of China's boiler.

2.It's the national designated A-class boiler and D1,D2 class pressure vessel manufacturing key enterprises and has passed ISO9001 international quality management certification system certification.It holds level 1 boiler installation permit. National special equipment manufacturing license ,National specialequipment installation remould maintenance permits and so on.

Our Factory

Our main products include circular fluidized bed (CFB) boilers, gas boilers, coal boilers, biomass boilers, oil boilers, power plant boilers, energy efficient boilers, slag boilers, efficient boilers, electric boilers, high pressure boilers, fully automatic Control of boilers, wood vapors biomass boilers, chain grate, condensing boilers, natural gas steam boilers, water pipe boilers, fire pipe boilers, all artificial intelligence boilers, biomass steam generators, refractory materials, boiler accessories and so on.

Service purposes:

1. Focus on customers, the pursuit of excellence, and customers to progress together;

2. Customer demand is our eternal pursuit;

3. Sell a boiler, build a demonstration project, pay a friend, open up a market is my company's business philosophy.

Похожие товары

1200000 ккал, горелка для древесной стружки, кукурузный стебель, горелка для котла и сушилки

Экономичная технология возобновляемой энергии, малогабаритная горелка на биомассе большого размера

Небольшой газификатор биомассы для продажи Высокая емкость древесных гранул горелка котел

Промышленная биомасса, горелка для древесных гранул, машина для производства биомассы, горелка для продажи

Промышленная древесно-гранулированная горелка, горелка для биомассы, опилки для парового котла, опилки для парового котла

Хорошее качество низкий уровень шума древесных опилок гранул биомассы горелка машина

Горелка на биомассе в гранулах, горелка на древесном грануле, горелка на биомассе с распылителем, горелка для котла

Новые поступления

Новинки товаров от производителей по оптовым ценам