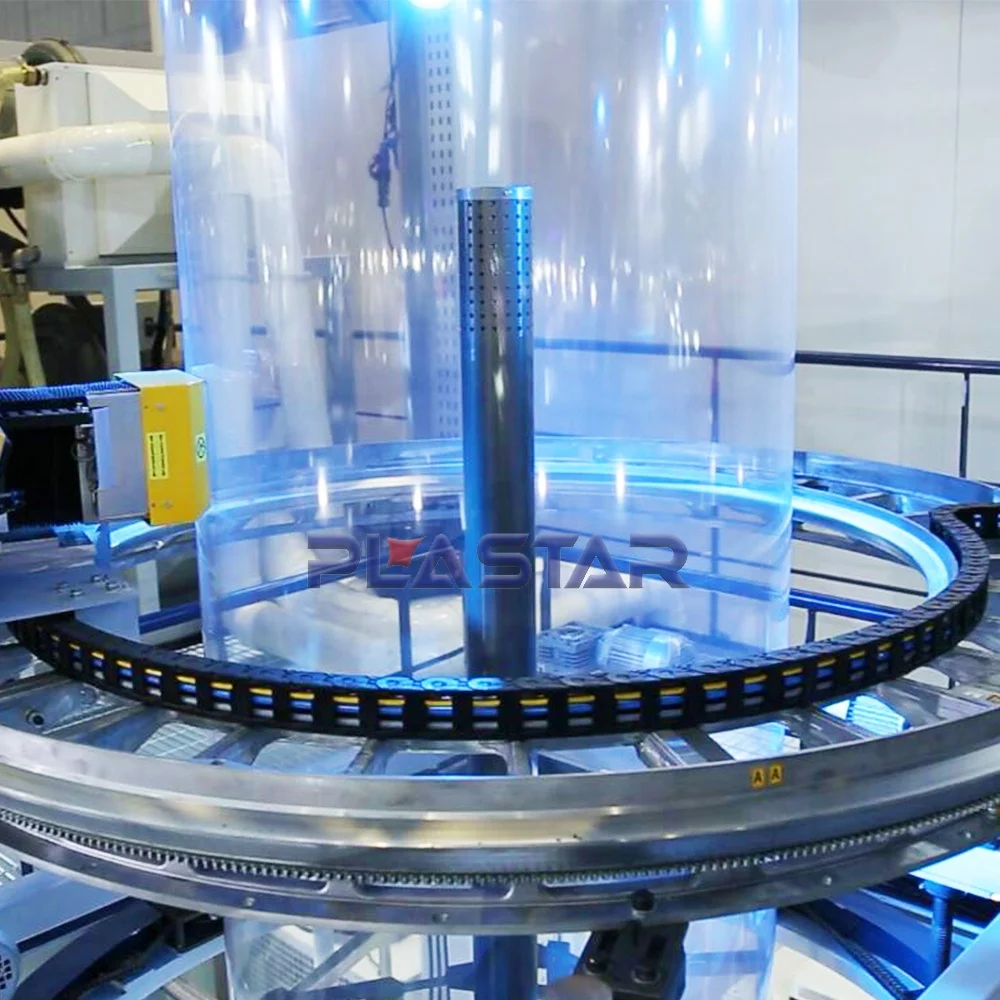

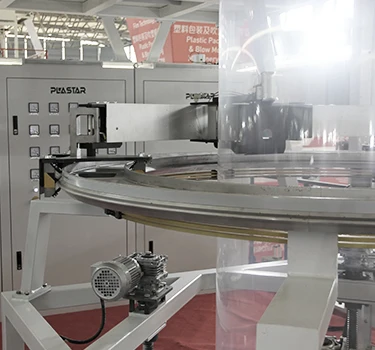

Инновационная пятислойная компрессионная машина для производства пластиковой пленки

- Категория: >>>

- Поставщик: Wenzhou Aoxiang Packaging Machinery Co. Ltd.

Сохранить в закладки 60799890123:

Описание и отзывы

Характеристики

Product Application

five layers air column bag blown film extruder for Electronic device packaging use for Stand-up pouch, Soft tube (tooth paste tube), Beverage pack, Lamination film, Protection film, Stretch film, Stretch hood heat shrinking film, medicine and food packing.

SPECIFICATIONS FOR FIVE LAYERS AIR COLUMN BAG BLOWN FILM EXTRUDER | ||||||

FEATURE | MATERIAL TO BE USED | PE PA PP EVA EVOH TIE (CUSTOMRISED, PLEASE ADVISE MATERIAL) | ||||

MAX. FILM WIDTH | MM | 800-1600 | ||||

THICKNESS OF FILM | MM | 0.02-0.2 | ||||

THICKNESS TOLERANCE | +-2-3% | |||||

MAX. EXTRUSION OUTPUT | KG/H | 480 | ||||

SCREW DIA. | MM | 65 X 4; 80 X 1 | ||||

SCREW L/D | 30:1 | |||||

SCREW / CYLINDER | BI-METALLIC (38CRMOALA) HARDNESS 75 OR OVER | |||||

DRIVING MOTOR | KW | 45 X 4; 55 X 1 | ||||

DIES | MM | 400 | ||||

TEMPATURE CONTROL | ZONES | 29 | ||||

TYPE | FIXED TYPE / OSCILLATION TYPE | |||||

PINCH ROLLER | 165 X 1600L | |||||

TAKE-UP MOTOR | SERVO MOTOR 2.8KW | |||||

TAKE-UP SPEED | 45-80 M/MIN | |||||

WINDING UNIT | WINDING TYPE | DOUBLE STATION WINDER WITH AUTOMATIC BOBBIN CHANGE | ||||

EFFECTIVE WIDTH | 1600 MM | |||||

DIMENSION (LxWxH) | 14*10*12 M | |||||

OPTIONAL DEVICE | Gravimetric Dosing Unit | Osillating Take Up Unit | ||||

IBC (Internal bubble cooling computer control system) | Line Speed Synchronized with Computer Control | |||||

Thickness Measurement | Chiller | |||||

Thicknss controller | Heat Slitting Device | |||||

Automatic Hopper Loader | EPC / CPC (edge / center Position Control) | |||||

Film Surface Treater | Electronic Tension Control | |||||

Pressure Gauge | Crane for Air Shaft | |||||

Automatic Gauge Control With Automatic cooling ring | Rotary Die | |||||

*Specification are subject to change without notice for improvement five layers air column bag blown film extruder will be customerised according to the material to be used, The film specification that going to produce, and application of the film | ||||||

Main Features

1) Simple structure with automatic device ,easy in installation and maintation.

2) Auto thickness profile control (auto Air Ring, Italy made)

3) 360 degrees thickness profile measurement with Osillating system (German technology)

4) Gain in weight dosing unit (italy made)

5) IBC computer control system

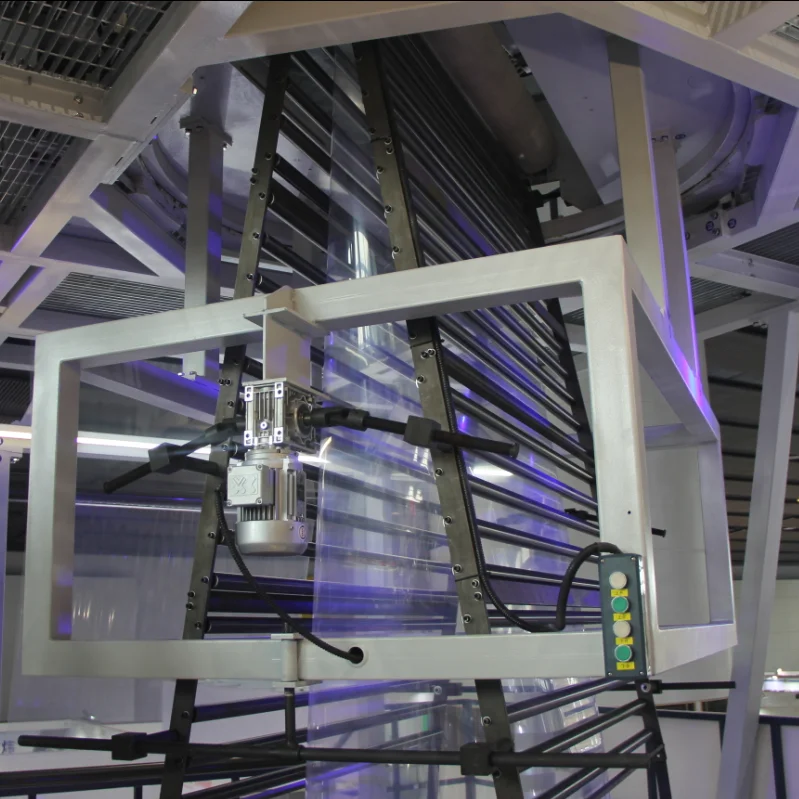

6) Horizontal Osillating take up unit.

7) Back to Back automatic surface type winder.

Machine Parts

Name: Auto Air ring & Dosing unit

Brand: Doteco

Original: Italy

control the film thickness automatically, and dosing material automatic.

Main Features

Name: Thickness Measurement

Brand: Kundig

Original: Switzerland

measure the film thickness automatic, cooperating with automatic air ring, make the film thickness tolerance +-2-3%.

Machine Parts

Name: Osillating take-up unit

make the film have good stretch ability, and the film will be more smooth.

Main Features

Name: EPC (edge position correction)

Brand: BST

Original: Germany

high precision and make the film winding good film roller.

Question 2. What certificates do your blown film machines have?

Our factory fully implements the ISO9001:2015 quality management system and has passed the TUV certification, which covers the design, production, and delivery. We also have the Swiss SGS certification and EU safety CE certification, which can meet the safety requirements of most countries in the world.

Question 3. What are the main markets of your blown film machines?

As of December 2019, our blown film machines had been sold to 93 countries around the world, mainly including China, Europe, the Middle East, Southeast Asian, the United States, Canada and Latin American countries.

Question 4. What is the general delivery time of blown film machines?

The production of a blown film machine usually takes about 30 to 60 working days, depending on the size and configuration of the machine.

Question 5. How long is the warranty period of blown film machines?

All our blown film machines have a one-year warranty, starting from the date of machine arrives at customer's factory and finished commissioning. During this period, we will provide a fully free warranty for the whole machine, except consumables.

Question 6. Can I visit the blown film machine production plant and watch the commissioning process?

Of course you can. we welcome you to visit us at any time. We will pick you up at Wenzhou Longwan Airport or Rui’an Railway Station.

Question 7. Where is the blown film machine factory?

Our factory is located in Wanquan Industrial Zone, No. 104 National Road, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province, China. You can take a plane to Wenzhou Longwan Airport or take a train to Rui’an Station. Please make an appointment with us in advance, and our driver will pick you up when you arrive.

Question 8. What kind of after-sales service do you provide if the blown film machines encounter technical problems or part damage?

We will remotely communicate with you via video to tell you how to solve technical problems of blown film machines. If the problem can't resolve, we will send engineer to your factory. If the damaged part (non-consumable part) is within the warranty period, we will provide you with another one free of charge, with the transportation charges paid by our factory.

Question 9. What is the payment method for blown film machine orders?

We will start production when we received the 30% deposit of the order. After we finished the production and received the last 70% payment, we will arrange shipment and send machine to customer.

Похожие товары

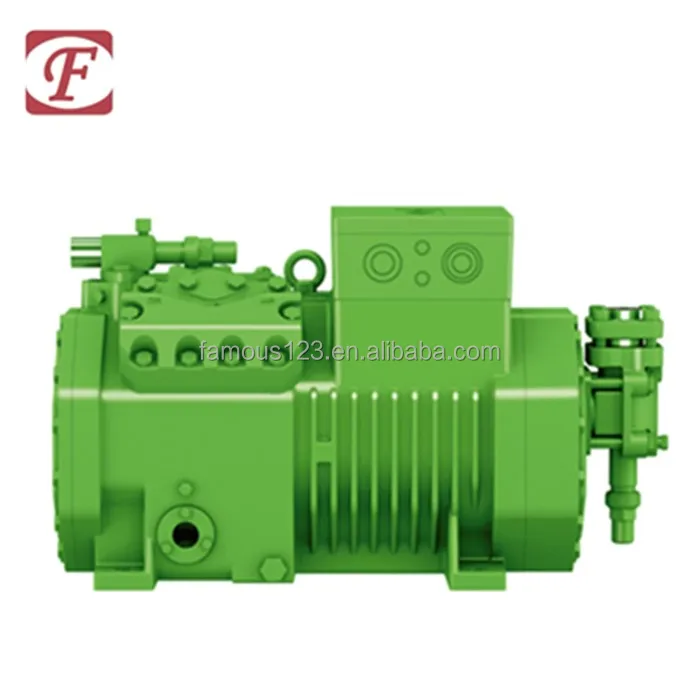

Полугерметичный возвратно-поступательный компрессор новой серии ECOLINE 4hp по финальной цене 2CES-4Y

4HP полугерметичных с возвратно-поступательным движением 4FES-4Y-40S холодной комнаты холодильная установка компрессора кондиционера для автомобиля

Рабочие рабочие перчатки для строительства разумная цена желтые рабочие перчатки с хлопковой спинкой

Новые продукты из нержавеющей стали 5HL 10HL 20HL микро Inox резервуары для производства вина

Бесплатная доставка Прозрачный 16 oz laserable стеклянная пивная кружка пивной посуды изготовленным на заказ логосом пивной бокал чашки кружки

Новая коллекция, набор керамической посуды хорошего качества, 4 шт. 3D футбол с крутым дизайном ручной росписи керамика из Таиланда

Профессиональная электрическая автоматическая машина для циркуляции воды с функцией подачи керамической водоструйной плитки

Новые поступления

Новинки товаров от производителей по оптовым ценам