Машина для изготовления потолочных панелей из ПВХ машина стен пластиковых

- Категория: Экструдеры для пластика >>>

- Поставщик: Zhangjiagang Xinhe Machinery Co. Ltd.

Сохранить в закладки 60801724429:

Описание и отзывы

Характеристики

Screw Loader | 1 set |

Twin Conical Screw Extruder | 1 set |

Mould | 1 set |

Vacuum Calibration Table | 1 set |

Haul-off machine | 1 set |

Laminator machine/hot stamping machine | 1 set |

Cutter Machine | 1 set |

PVC Mixer Machine | 1 set |

PVC Crusher | 1 set |

PVC Pulverizer machine | 1 set |

PVC Ceiling Panel Feature

1.PVC ceilicing panel are the ideal way to deliver tempered air from preheated hallways to farrowing or nursery rooms. The hollow profile acts as an air plenum delivering the air through precisely sized and positioned holes. The air enters the room uniformly without creating drafts.

2.it is light in weight, moisture resistant and reduces condensation and subsequent dripping from ceiling onto work surfaces. The cleanable, non-absorbent surface is UV stable and will not discolour.

3. solves the problem of dirty, unhygienic ceilings that are difficult, and expensive to clean by providing a bright, durable and hygienic surface, which is easily maintained. This extremely practical ceiling system is suitable for any area requiring a fixed, non-porous, non-fibrous and non-absorbent ceiling.

4.PVC ceilicing panel has various advantage over other materials namely they are waterproof, Termite Proof, Fire Retardant, Economical, Maintenance free, being non-porous and non-absorbent, can incorporate flush fitting lighting, access hatches, air vents and sprinklers easy to install & available in various colours shades & no hassles of Painting & Polishing.

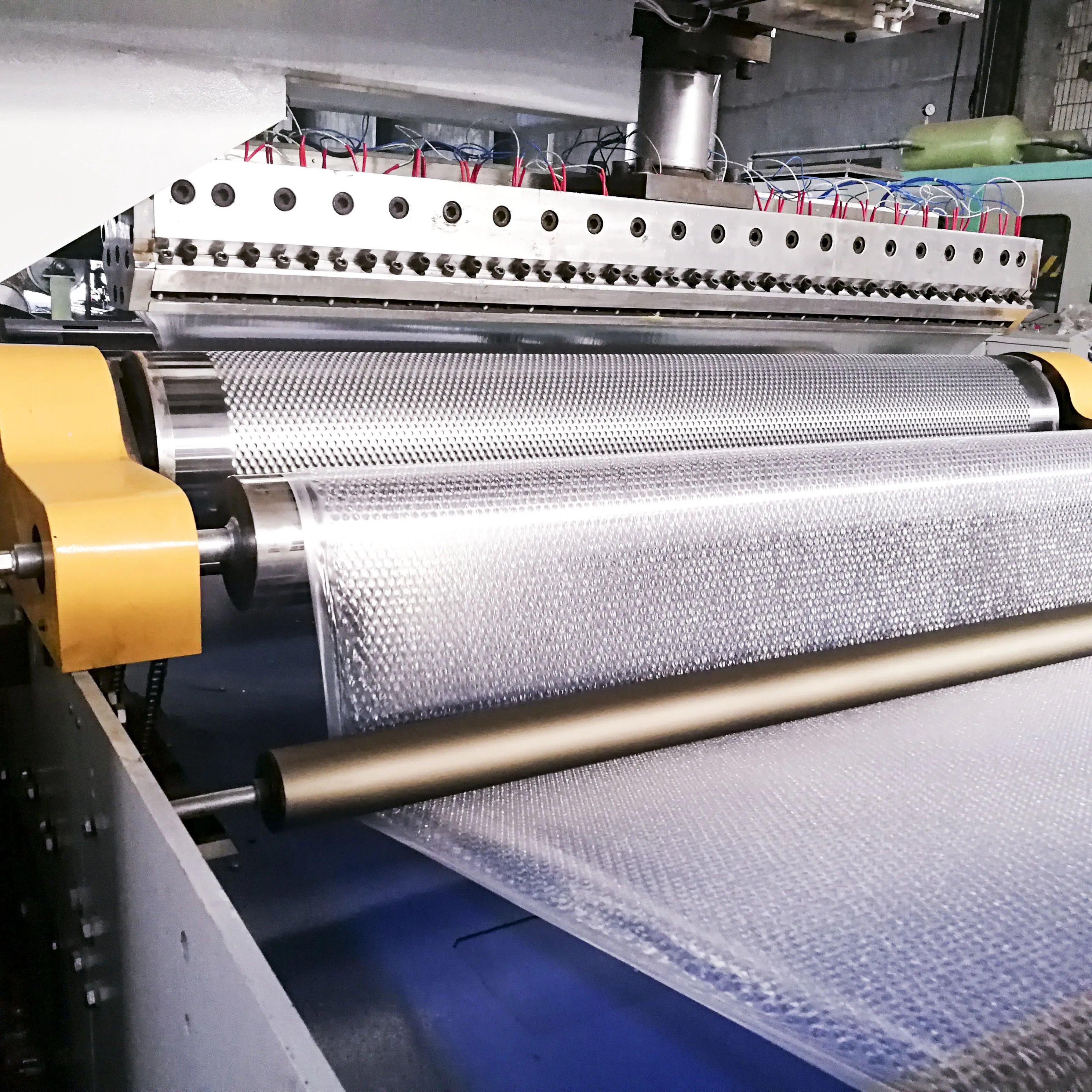

High quality PVC Ceiling Panel Production Line.

This line has stable running,high output,low sheering force,long life service and other advantages. The production line consists of control system, conical twin screw extruder or parallel twin screw extruder,extrusion die, calibration unit,haul off unit, film covering machine and stacker. The extruder is equipped with alternating-current inverter (ABB or Eurotherm drive), imported temperature controller (RKC,Japan). The calibration unit's pump and haul off unit's reducer are famous brand products. After simple changing of the die and screw.

Zhangjiagang Xinhe Machinery Co., Ltd.

We are a scientific and technological company integrating scientific research, production, sales and service. We mainly produce plastic extruder, plastic profile pipe sheet sheet cleaning and recycling granulation extrusion production line, PE/PP/PVC wood plastic production equipment. , waste plastic granulator, series high-speed mixing unit, drying, feeding, crushing, grinding and other peripheral equipment READ MORE

We are very professional and can customize any production line you need.

Our Customers

A: Conical Twin Screw Extruder: Specially screw design according to different materials make the high polymer micro-foam uniform plasticization, high extrusion. Imported famous brands AC inverter makes the rotation speed stable to ensure the main extruder and accessory machines move synchronously.

Vacuum calibration table: Powerful turbo cooling system, easy to achieve satisfactory cooling effect. According to different moulds and different customer requirements

Haul off machine: Adopts special lifting technology, and has the features of stable running, reliable working, powerful hauling etc.

2. Q : How will you offer me the quotation if I'm not very familiar with this production line?

A: You can send me you requirements on the products you want and I will recommend you with the most suitable production line and also the quotation for that.

3. Q: How many years warranty of the line ?And other Service ?

A: The product of the electrical part is guaranteed for 6 months, and the mechanical part is guaranteed for 1 years. Oversea technician service is available.And our company provides the door-to-door service of installation and commissioning. We also have offices in Vietnam, Bangladesh and Indonesia. (Changing parts or repairing is available during the warranty time)

4. Q : How about your delivery time ?

A: Normally we need 45-50 days for the production time after receiving your 30% of the deposit.

5.Q: What`s the Trade term and payment term do you accept?

A : Fob or CIF are both available.

Payment that we accept : 100 % T/T (30% deposit + 70% before shipment )

6.Q: Is Xinhe a factory or trading company?

A: We are professional manufacturer for the plastic production line and has been in this area for over 20 years.

Похожие товары

603*603*7 мм ПВХ квадратная потолочная производственная линия, ПВХ 595*595 мм машина для производства внутренней крыши

Линия по производству дверных панелей из ПВХ

Шанхай Shenxin высокоскоростная фабрика точно изготовленная пластиковая воздушная пузырчатая пленка, рулон листа, производственная машина

Машина для производства листов пенопласта EPE/Экструзионная линия ПЭ-труб из пенопласта, модель Элли Whats 008613780912769

Высокоскоростная производственная линия для экструзии полиэтиленовых труб ПЭНД LDPE 16-63 мм

Машина для производства одноволоконной пряжи ПЭТ ПП ПЭ машина для экструзии пластиковой волоконной пряжи

Полностью автоматическая линия по производству пленки с 7 слоями воздушных пузырей

Новые поступления

Новинки товаров от производителей по оптовым ценам