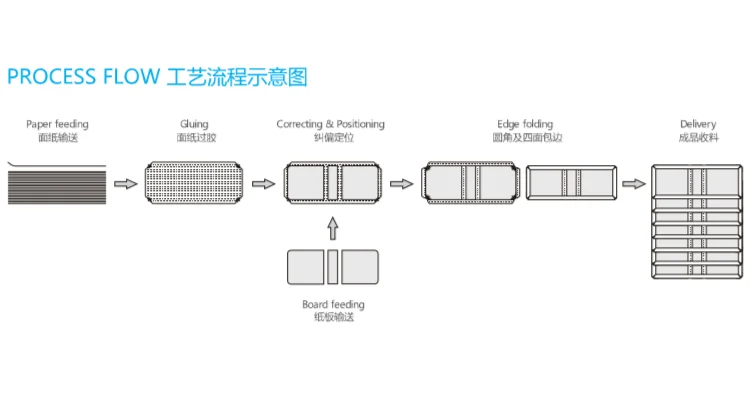

Фотобумага и машина для резки и резки коробок

356 320,37 ₽ - 416 936,04 ₽

Сохранить в закладки 60803247385:

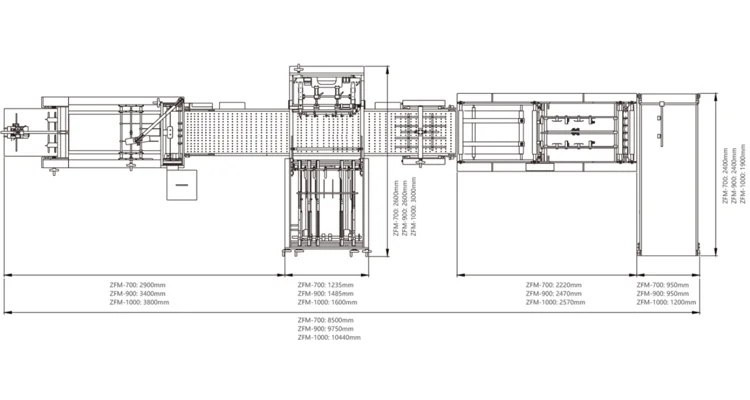

Model | ZFM-700A | ZFM-900A | ZFM-1000A | ZFM-1350A |

Maximum Size | 450mm×720mm | 450mm×950mm | 600mm×1050mm | 600mm×1350mm |

Minimum Size | 90mm×180mm | 90mm×180mm | 140mm×240mm | 140mm×240mm |

Board Thickness | 1.0-3.0mm | 1.0-3.0mm | 1.0-3.0mm | 1.0-3.0mm |

Paper Weight | 105-210g | 105-210g | 105-210g | 105-210g |

Maximum Speed | 20-30 picecs/min | 20-30 picecs/min | 15-25 picecs/min | 10-20 picecs/min |

Power Supply | 16KW/380V | 17.5KW/380V | 18KW/380V | 19KW/380V |

Dimension(L×W×H) | 8500× 2600×1500mm | 9750× 2600×1500mm | 10440×3000×1500mm | 11500×3000×1500mm |

Machine Weight | 3500kg | 4000kg | 5000kg | 6000kg |

Position Accuracy | ±0.25mm | ±0.25mm | ±0.25mm | ±0.25mm |

Boards amount | 1-6pieces | 1-6pieces | 1-6pieces | 1-5pieces |

Min spine width | 8mm | 8mm | 8mm | 8mm |

Min side-board width | 25mm | 25mm | 25mm | 25mm |

Новинки товаров от производителей по оптовым ценам