Automatic Breakfast Cereal Corn Flakes Making Machine Plant

- Категория: >>>

- Поставщик: Jinan Shengrun Machinery Co. Ltd.Jinan Ltd.

Сохранить в закладки 60803318559:

Описание и отзывы

Характеристики

Automatic Breakfast Cereal Corn Flakes Making Machine Plant

Automatic Breakfast Cereal Corn Flakes Making Machine Plant

This line takes corn flour and other grains flour or grain grits as raw materials. It includes mixing, extruding ,flaking, drying ,high temperature baking, flavoring ,cooling . The whole line is automatic. The corn flakes shaped by the machine is crispy .

Machine introduction

Machine | Machine Application | |

1 | Mixer | Mixing various flour materials evenly |

2 | Screw Conveyor | Transfer the raw materials to extruder by uniform speed |

3 | Twin screw Extruder | Extruding the raw materials and shape the extruded products into corn balls |

4 | Vibrating screen | Cooling and feeding the corn flakes to drum evenly |

5 | hoister | Hoisting the extruded products into the separating drum |

6 | Separating Drum | Cooling and feeding the corn balls to flakes machine |

7 | Air conveyor | Transfer the corn balls to flakes machine |

8 | Flaking machine | Make the corn ball to corn flakes |

9 | Roasting oven | Baking the moisture in corn flakes |

10 | hoister | Transfer the corn flakes to the vibrating screen |

11 | Vibrating screen | Separating the sticky corn flakes and feeding it into the high temperature inflated oven |

12 | High-temperature inflated oven | the corn flakes will be dryed twice in this oven |

13 | Single Drum flavoring line | Spray seasoning powder or sugar onto the corn flakes so as to makes it tasteful |

14 | Drying oven | Baking the moistrue in corn flakes after seasoning |

15 | Cooling conveyor | Cooling and feeding the corn flakes to packaging machine |

Model | TSE65 | TSE70 |

Installed power | 130kw | 160kw |

Power consumption | 90kw | 120kw |

Production capacity | 100-150kg/h | 150-200kg/h |

Dimension | 39*2*3m | 42*2*3m |

We can make it according to customers' Local voltage according to different countries (400v/ 415v /480v.).

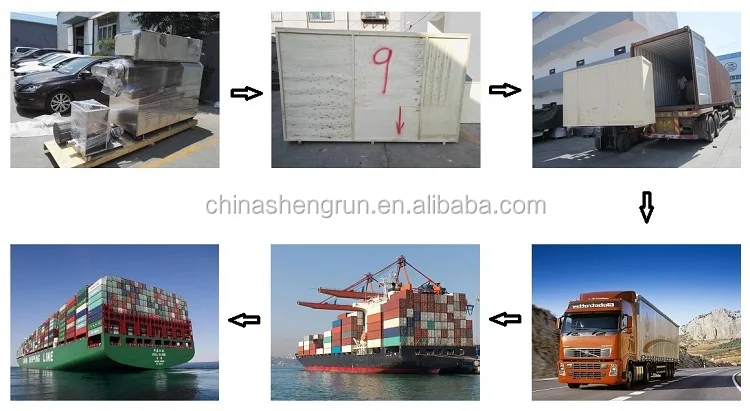

A. We will pack all necessary machines into wooden cases. For drying machine, and heavy extruders, we will fix them in the container with very strong iron wire.

B. If by LCL for small quantity machines, we will let send to QINGDAO port for loading.

C. If need containers, our trucks will take the containers from port to our factory for professional and safely loading, and then return to port for shipment.

1. Consultation service before, during,and after sales;

2. Project planning and design service;

3. Debugging of equipment until everything is functional;

4. Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5. Training of equipment maintenance and operating personally;

6. New production techniques and formulas;

7. Provide 1 year complete warranty and life-time maintenance service

1. 9 years manufacturing experience

2. Exporting to many countries, rich exporting experience

3. Approved by CE,ISO,SGS

4. Professional sales and after sales team, engineer available to serve overseas

Q1. Are you a manufaturer or a trading company?

Answer: We are a professional manufaturer with trading department.

Q2. Could we visit your company to check the machine?

Answer: Of course! Highly appreciated your visit to our company.

Q3.Could you provide customized machine?

Answer: We can manufacture the machine as your request.

Q4.What’s your payment system?

Answer: Usually T/T: 30% deposit,70% payment before delivering the goods. Or 40% deposit,60% payment before delivering the goods.

LC is also acceptable.

Q5: Do you have your own shipping agents?

Answer: Yes,We have long-term cooperation shipping agents. We can ensure the safety delivery of the goods.

Q6:How about the installation ?

Answer: We can dispatch our technician team to guide you the installation and teach you how to operate the machine.

Похожие товары

полный автоматические производственные машины для различный вид конфеты

Лидер продаж комбикормовая грануляторная машина для животных

Малая машина для наливания риса экструдер кукурузы типа оболочки (whatsApp:+ 86-15639144594)

Южноамериканская популярная Лебеда и кукуруза оборудование для производства закусок

Универсальные небольшие машины для домашнего бизнеса с достаточным запасом

4KW бензиновый портативный генератор для домашнего использования 3 75kva 230 В/50 Гц однофазный с автоматическим и возвратным запуском ISO9001 сертифицирован

Энергосберегающий генератор азота высокой чистоты/генератор завод/генератор пищевой промышленности

Новые поступления

Новинки товаров от производителей по оптовым ценам