Фидер из циркониевой керамики для круговой вязальной машины керамический Цирконий

- Категория: Запасные части для текстильных станков >>>

- Поставщик: Yixing ZF Ceramic Factory

Сохранить в закладки 60803690101:

Описание и отзывы

Характеристики

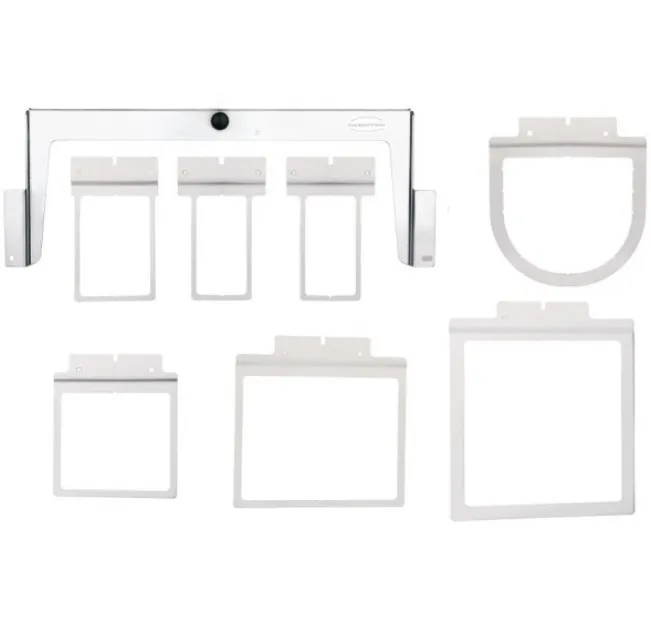

1. Name: Zirconia ceramic feeding nozzle with iron

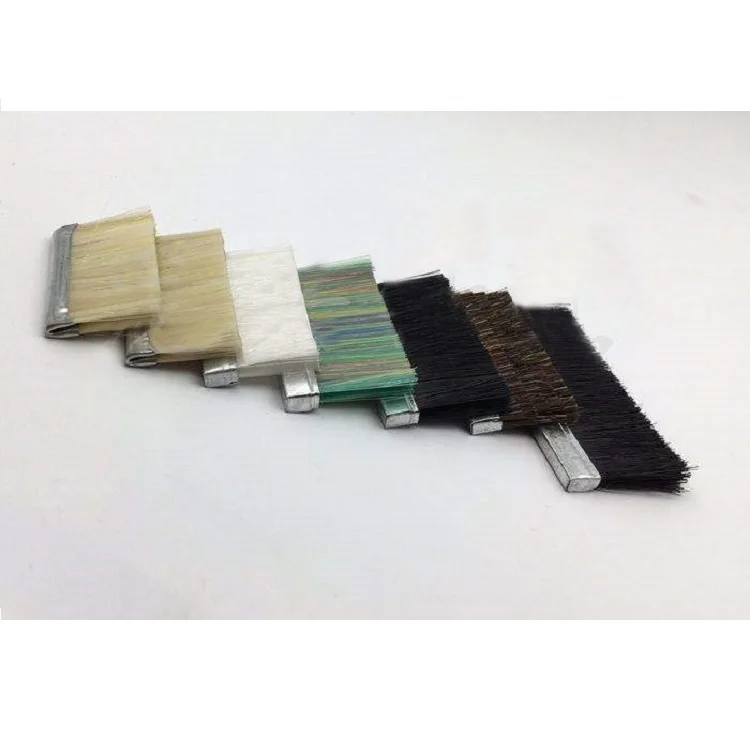

2. Color: Solid white/black

3.Product advantages: zirconia ceramics have the advantages of high hardness, good wear resistance, high toughness, low friction coefficient and good corrosion resistance.Widely used in textile machinery, mechanical seals, ball grinding medium, cutting tools, ceramic bearings, auto engine parts, paper machine dehydrating equipment.

4.Other:Note that this product can be purchased solely from the ceramic part,can also be bought together with iron piece, specific price please ask the seller before purchase it!

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

Our factory provides: pressing molding - processing - firing - blackening - polishing, one - stop service..

Larger quantities and more favorable prices.

Factory

Workshop

Our Workshop

Workshop

Our Workshop

Workshop

Our Workshop

1.Materials: to meet the different requirements of customers, to import Germany, Japan high-performance ceramic powders.

At present, there are 94,96,99,99.7 alumina powder, 3mol yttrium stabilized zirconia powder, ultra-pure titanium oxide powder, zirconium toughened alumina powder (ZTA), etc

2.Molding technology: hot pressing molding is conducive to the production of structural product shape, size, complex shape, high-precision requirements of products

Professional zirconium porcelain black technology: vacuum carbonization black technology, mainly used to improve its wear resistance.

Each batch of products will be checked manually three times before packaging to ensure product quality.

Each batch of products will be checked manually three times before packaging to ensure product quality.

Each batch of products will be checked manually three times before packaging to ensure product quality.

Packing Details : The products are packed in cartons, wrapped with self-mucous membrane. (the products can be packed in plastic boxes.)

Delivery Details : Generally, the delivery time is 7-30 days.The products can be sent to Shanghai port or sent to customers by express mail

Похожие товары

Оптовая продажа, плоская кисть для вязальной машины, запчасти для текстильных машин

100 шт. DCX27 Q.X.YUN аксессуары для швейных игл для промышленных швейных машин Pegasus Siruba

Поршень с втулкой для установки автоконера schlafhorst хорошего качества

YJ-70A автоматизированная швейная машина для нарезки электрические ножницы нож круглый

Высококачественная одежда для текстильной картонной машины LICKERIN

Иглы для плоских вязальных машин vo-spec parts 112,70-62 G01

PN180500077 Ремень ГРМ швейная машина запасные части подходит для GT7250

Новые поступления

Новинки товаров от производителей по оптовым ценам