Полностью Автоматическая производственная линия по производству якоря двигателя ротора

- Категория: >>>

- Поставщик: Ningbo Nide Mechanical Equipment Co. Ltd.

Сохранить в закладки 60804914032:

Описание и отзывы

Характеристики

Fully auto motor armature rotor manafacturing production assembly line

I. The armature rotor production line introduction:

This automatic produciton assembly line is used for the manufacturing production of motor rotors (commutators can be hook or groove).

The automatic motor armature manufactuing line is transmitted by the belt conveyor line, and the front and rear machines can be connected according to a predetermined communication protocol to realize intelligent automatic production, and the workpiece transfer, loading and unloading, detection, and production process transfer can be completed without manual intervention.

The motor rotor production assembly line consists of the main operating table (including the upper and lower feed ports), the rotor shaft pressing machine, the rotor commutator pressing machine , the automatic rotor insulation paper insertion, the double flyers armatur rotor coil winding machine, and the fully automatic rotor commutator spot welder, the automatic rotor slot wedge insertion machine, the armature rotor commutator turning machine, the armature rotor deburring machine, the fully automatic rotor integrated testing machine.

These machines form an automatic rotor production line through belt conveyors.

The workpiece is placed in the production line from the console.

The entire production line will complete the corresponding process according to the relevant process.

Finally, it will be recycled back to the lowering port to remove the completed workpiece.

Each process equipment has functions such as separate setting, display, operation, sound and light alarm.

II. Performance and characteristics

1. This automatic rotor manufacturing production line includes armature shaft presser, armature rotor commutator press, rotor insulation paper automatic inserter, double fly fork armature rotor winder, fully automatic rotor commutator spot welder, automatic armature rotor slot wedge inserter , rotor commutator finishing turning machine, rotor commutator deburring machine, and fully automatic armature rotor testing machine.

2. The complete rotor manufacturing line equipment can be automatically connected or operated independently.

3. Advanced and sophisticated host manufacturing technology combined with a powerful belt conveyor system for a variety of different planar configurations.

4. It has the advantages of simplicity, flexibility, high efficiency and reliability, which can greatly save manpower, reduce labor intensity and effectively improve production and quality.

5. High-strength all-aluminum frame structure, simple and elegant appearance.

6. The main operation console can perform centralized display monitoring and inquiry on the entire production system, and can read and write the process status of the product by manual input instructions, which can change the process of processing the product, and the operation is more humanized.

7. Compared with the pneumatic conveying line, the transmission efficiency is higher, the noise is smaller, and the workpiece is not damaged during transportation; the belt conveying structure combined with the intelligent identification system realizes flexibility from hardware and software, and makes the wiring more flexible and diverse.

8. The whole rotor manufacturing line adopts automatic identification control system. Each process can automatically read, write and identify the machining status of the workpiece, so that the line body can better adapt to complex and diverse production process requirements.

9. Customers can configure different models into a highly efficient and practical automatic production line according to the actual conditions such as product type, technical indicators and production requirements.

III.The main equipment parameters

We can customize the machine according to customer needs, please contact us if you need it.

a. Auto armature rotor commutator pressing machine parameters

Product name | Motor armature commutator pressing machine |

Armature O.D: | 20-60mm |

Shaft O.D: | 3-15mm |

Shaft length: | 32-250mm |

Armature slot number: | 8-24 slots |

Commutator O.D: | 8-40mm |

Speed amplitude modulation: | 0-670Hz |

Air source: | 6-6Kg/cm2 |

Total power: | 1.0KW |

Power source: | AC220V,50/60Hz |

Weight: | About 400Kg |

Dimension: | 910*880*1300mm |

b. Double flyer winder armature coil winding machine parameters

Product name | Armature rotor coil winding machine |

Wire diameter: | 0.25~1mm |

Armature O.D: | 20~60 mm |

Armature stack length: | 10~60 mm |

Slot type: | straight slot(No more than 36 slots) |

Armature slots number: | Odd, even slot |

Counting Range: | 0~99999 |

Commutator diameter: | 18~40 mm |

Fly fork speed: | 0~3000 rpm |

Indexing speed: | 0~3000 rpm |

Action process: | Single action, automatic |

Air pressure : | 4~6 Kg/cm2 ,0.5-0.7MPa |

Machine power: | 4KW |

Temperature: | -10~40℃ |

Humidity: | 40~90% |

Power supply: | 3phase 380V±10% 50/60 Hz |

Total weight: | about 1,180 Kg |

Dimension: | 2000(length)×1300(width)×1800(height) mm3 |

Production efficiency: | 800-900set/class(calculated based on 12slots 24hooks, 20turns) |

c. Fully auto motor armature commutator spot welding machine parameters

Product name | Armture commutator hotstaking machine |

Loading method: (choose any one from the following three methods) | 1.Manually loading/unloading 2.Manually push guide rail to load/unload 3.Cylinder loading/unloading |

Indexing method: | servo indexing |

Commutator type: | hook or riser |

Wire diameter: | 0.2mm-1.0mm |

Armature diameter: | 20mm-60mm |

Armature Stack length: | 10mm-60mm |

Shaft length: | 50mm-250mm |

Commutator diameter: | 10mm-40mm |

Shaft diameter: | 3mm-17mm |

Commutator hook/riser number: | ≥3 |

Zero finding method: | manually place armature, cylinder drive one block for positioning |

Pressure control method: | spring + cylinder + pressure detection |

Welding head cooling method: | water cooling |

Parameter setting: | set on the touch screen and power source , Parameter also can be set |

Power source control method: | close loop feedback, high accuracy , inversion |

Compressed air pressure: | 4kg/cm2-6kg/cm2 |

Welding source power: | three phase AC380V±10% 50HZ 40KW |

Water cooler power: | three phase AC380V±10% 50HZ |

Machine weight: | 800kg(for reference) |

Dimension: | 785(L)x 910(W)x 2100(H)mm 3 (for reference) |

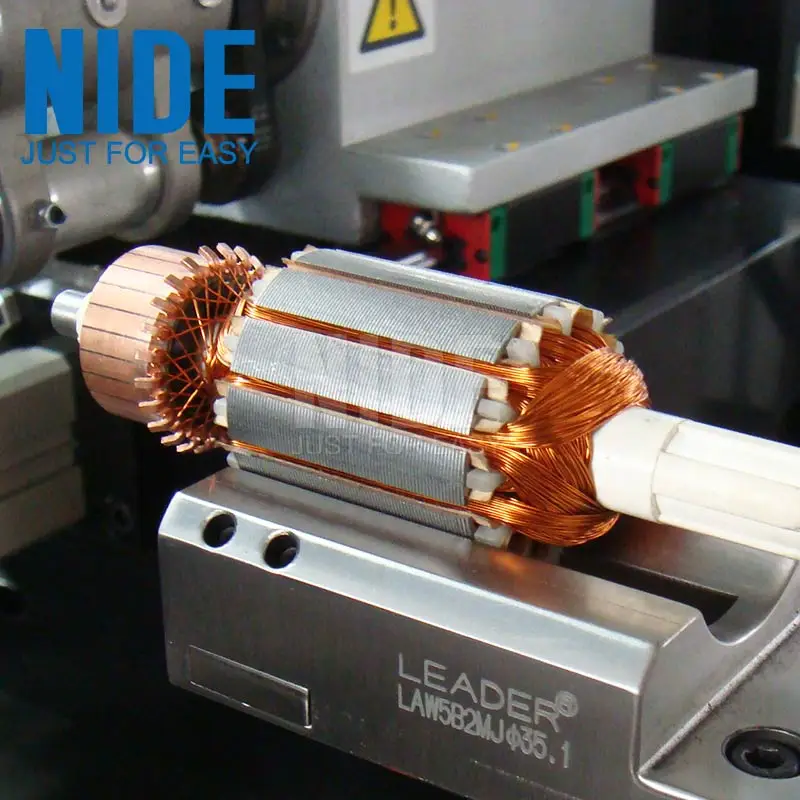

IV.The main equipment picture display

1.The double flyer armature rotor coil winding machine

2. The armature commutator spot welder hot staking machine

3.The armature rotor commutator turning machine

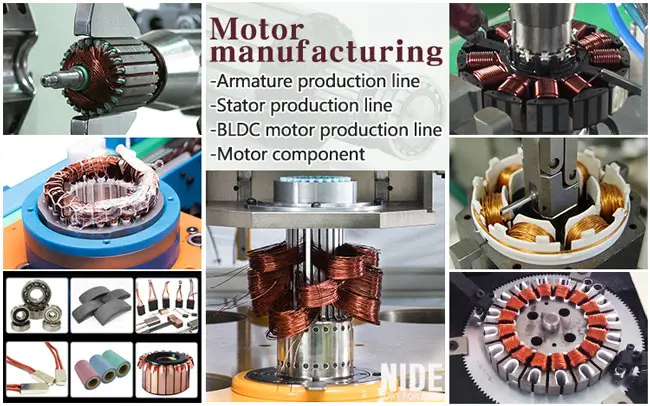

Motor armature rotor manufacturing assembly line including: shaft pressing machine, end cover pressing machine, commutator pressing machine, armature insulation paper inserting machine, armature winding machine, commutator hot stacking machine, armature wedge inserting machine and armature testing machine, ball bearing inserting machine, and worm shaft inserting, NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

With good service, unique philosophy, professional team and reliable quality, we win the worldwide customers' confidence gradually. We directly and indirectly supply our products to more than 50 countries.Among the customers, many of them are the world-renown companies.

| Customerized service | 1. Customized product design and manufacturing |

| 2. Customized tranning | |

| 3.Technical suggestions | |

| After-sales service | 1. Warranty Period: 12 month usually |

| 2. Overseas service center available | |

| 3. Engineers available to service overseas |

Established in 2007, Nide is a company devoted in the field of electric motors manufacturing, providing one-stop service for its customers.

Nide has three main business divisions.

The first division is to provide different kinds of motor manufacturing machinery, it is our Main business, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.

The second division is to supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.

The third division is to provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Похожие товары

Костюм робота с поддержкой талии, механизированное умное переносное устройство с экзоскелетом

DEVOPS большой размер плоская светодиодная панель Android сенсорный экран 75 дюймов интерактивная панель

Установка для автоматического заправки газов, 20 использований для инжектора AEB, Италия

Матрас Sunsgoods двухразмерный из мягкого трикотажного хлопка, матрас с вакуумным сжатием из пены с эффектом памяти, матрас с пружиной

Бытовые садовые инструменты, мини-садовый набор инструментов в горшках, многофункциональная Бытовая Лопата для растений

Воздушный компрессор для дайвинга на 300 бар, насос для наполнения газовым баллоном

Термостойкий перевернутый паровой клапан из нержавеющей стали для гофрированной линии

Новые поступления

Новинки товаров от производителей по оптовым ценам