Воздушные компрессоры производитель воздушных компрессоров Atlas Copco Ga 11

- Категория: >>>

- Поставщик: Shanghai Compressor Service Co. Ltd.

Сохранить в закладки 60805245896:

Описание и отзывы

Характеристики

Air Compressors - Atlas Copco Ga 11 Air Compressor Manufacturer

Atlas Copco

Rotary compressor

Screw air compressor

GA75 plus FF

75kw 100hp

Atlas Copco Oil-injected Rotary Screw Air Compressors

Model GA30+ GA37 GA37+ GA45 GA45+ GA55 GA55+ GA75 GA75+ GA90 GA37VSD GA45VSD GA55VSD GA75VSD GA90VSD

We develop innovative sustainable solutions that create value for our customers in more than 180 countries. Our expertise is in compressors, vacuum solutions and air treatment systems, construction and mining equipment, power tools and assembly systems.

Best price GA 30+-90 / GA 37-90 VSD: Oil-injected rotary screw compressors, 30-90 kW / 40-125 hp

Efficient, reliable and built to last, the GA 90+-160+ / GA 110-160 VSD compressors are designed to provide high-quality compressed air even under harsh conditions. Every GA is designed, manufactured and tested to comply with ISO 9001, ISO 14001 and ISO 1217. They use the latest generation of Atlas Copco’s oil-injected screw element, ensuring a long and trouble-free life at the lowest possible operating cost. Engineered for reliable service, even in ambient temperatures up to 55°C/131°F and very harsh environmental circumstances, the GA takes reliability to a new level. Features such as Variable Speed Drive and energy recovery lead to significant reductions in energy use and cost.

Total capability

Right at the heart of your business, Atlas Copco delivers quality compressed air for superior operational capacity. From compressed air generation to point of use, you can choose from our wide range of products to create a complete compressed air system tailored to your specific needs. All Atlas Copco products are engineered to integrate seamlessly, ensuring the highest level of reliability and energy efficiency. As a result,

Atlas Copco can take full responsibility for your compressed air infrastructure with a guarantee of best-in-class quality. With a global presence in over 150 countries, we can provide an unrivalled service to maintain and continually improve your compressed air system performance.

Atlas Copco can take full responsibility for your compressed air infrastructure with a guarantee of best-in-class quality. With a global presence in over 150 countries, we can provide an unrivalled service to maintain and continually improve your compressed air system performance.

Backed by 100 years at the forefront of compressed air, Atlas Copco products offer the finest quality and efficiency. Our goal is to be First in Mind—First in Choice™. That is why Atlas Copco’s pursuit of innovation never ceases, driven by the dedication to meet and exceed your demands. Always working with you, we are committed to providing the customized air solution that is the driving force behind your business.

Powerful efficiency

Integrated onto the production floor, Atlas Copco’s GA WorkPlace Air System™ provides a dependable flow of compressed air directly to the point of use. No need for a separate compressor room or an elaborate and costly piping system. Built to perform in harsh environments with the highest efficiency, the GA keeps your production running smoothly and reliably.

Assured reliability

The GA is designed, manufactured and tested in accordance with ISO 9001, ISO 14001 and ISO 1217, Ed. 3, Annex C. Ensuring a long and trouble free life at the lowest operating cost, the GA contains the latest generation of Atlas Copco’s patented oil-injected screw element, powered by a maintenance free drive system. Engineered to provide reliability even in ambient temperatures up to 55°C/131°F, the GA takes reliability to a new level.

The GA is designed, manufactured and tested in accordance with ISO 9001, ISO 14001 and ISO 1217, Ed. 3, Annex C. Ensuring a long and trouble free life at the lowest operating cost, the GA contains the latest generation of Atlas Copco’s patented oil-injected screw element, powered by a maintenance free drive system. Engineered to provide reliability even in ambient temperatures up to 55°C/131°F, the GA takes reliability to a new level.

Reduced energy costs

The cost of compressed air can represent over 40% of your total electrical costs. Atlas Copco wants to help you spend less. Our GA VSD (Variable Speed Drive) compressors can reduce energy costs by an average of 35% and overall compressor lifecycle costs (LCC) by an average of 22% by tuning compressor capacity to the air demand. The resulting energy savings have a substantial environmental impact, reflecting Atlas Copco’s dedication to safeguarding a healthy future for the generations to come.

The cost of compressed air can represent over 40% of your total electrical costs. Atlas Copco wants to help you spend less. Our GA VSD (Variable Speed Drive) compressors can reduce energy costs by an average of 35% and overall compressor lifecycle costs (LCC) by an average of 22% by tuning compressor capacity to the air demand. The resulting energy savings have a substantial environmental impact, reflecting Atlas Copco’s dedication to safeguarding a healthy future for the generations to come.

Air system integration

The GA WorkPlace Air System can be placed where you need it: the point of use. Its low noise operation and integrated air treatment equipment eliminate the need for a separate compressor room – reducing piping costs and internal system pressure drop. GA compressors are delivered ready for use, reducing installation costs to a minimum.

The GA WorkPlace Air System can be placed where you need it: the point of use. Its low noise operation and integrated air treatment equipment eliminate the need for a separate compressor room – reducing piping costs and internal system pressure drop. GA compressors are delivered ready for use, reducing installation costs to a minimum.

Customer benefits

Highest reliability– GA compressors incorporate the latest generation of Atlas Copco’s state-of-the-art compression elements based on innovative asymmetric rotor profiles, a high-quality drive system and heavy-duty air inlet filters. All these components are selected to operate continuously in the toughest conditions and at ambient temperatures up to 55°C/131°F. Together they ensure long and trouble-free life of your compressor at the lowest operating cost.

Maximum energy savings– The innovative design of our GA compressors (including screw element, motor, VSD-controlled cooling fans etc.) enables you to achieve substantial savings in your energy costs and overall compressor lifecycle costs. The GA Variable Speed Drive (VSD) reduces energy costs by a further 35% on average by automatically adjusting the air supply to your air demand. And to reduce your costs even further, install the optional energy recovery system.

Integrated air treatment– The GA Full Feature with highly energy efficient integrated refrigerant dryer and air filter ensures the continuous supply of clean and dry air to extend the life of equipment, enhance system reliability and avoid costly downtime and production delays.

Advanced control and monitoring– To maximize efficiency and reliability, the Elektronikon® controls the main drive motor and regulates system pressure within a predefined and narrow pressure band. The Elektronikon® controller can be adapted to your specific needs with extra sensors, digital contacts, fieldbus, Internet and SMS communication functions. In combination with the ES multiple compressor controller, the operation of your complete compressor room is optimized.

Easy installation– The integrated design includes internal piping, coolers, motor, lubrication and control system: all supplied as a ready-to-use package. Installation is fault-free and commissioning time is low. Simply plug and run.

Built to last

1).Maintenance free drive system

- The GA drive system is 100% maintenance free – eliminating the risks inherent to the greasing of conventional

motor bearings.

- Patented technology allows the drive system to run in ambient temperatures up to 55°C/131°F.*

2).Oil filter

- A high efficiency oil filter removes 300% smaller particles than a conventional filter, providing clean oil to extend

the lifetime of all lubricated parts in the compressor.

- The oil filter rating of ß12=75 sets a new industrial compressor standard that is fully compliant with ISO 16889.

3).Aftercooler with integrated water separator

- The GA’s aftercooler with integrated water separator immediately removes 100% of condensate – avoiding the

risk of corrosion in downstream equipment and improving air quality compared to conventional cyclone separators.

4).Electronic water drains

- The GA’s no loss drains eliminate the waste of compressed air that conventional drains create.

- The drains communicate with the compressor controller to ensure the constant removal of condensate.

- A large diameter drain port removes the potential for clogging, providing trouble free operation.

- The GA drive system is 100% maintenance free – eliminating the risks inherent to the greasing of conventional

motor bearings.

- Patented technology allows the drive system to run in ambient temperatures up to 55°C/131°F.*

2).Oil filter

- A high efficiency oil filter removes 300% smaller particles than a conventional filter, providing clean oil to extend

the lifetime of all lubricated parts in the compressor.

- The oil filter rating of ß12=75 sets a new industrial compressor standard that is fully compliant with ISO 16889.

3).Aftercooler with integrated water separator

- The GA’s aftercooler with integrated water separator immediately removes 100% of condensate – avoiding the

risk of corrosion in downstream equipment and improving air quality compared to conventional cyclone separators.

4).Electronic water drains

- The GA’s no loss drains eliminate the waste of compressed air that conventional drains create.

- The drains communicate with the compressor controller to ensure the constant removal of condensate.

- A large diameter drain port removes the potential for clogging, providing trouble free operation.

5).Electrical cubicle cooling booster

- The main cooling fan cools the electrical cubicle, ensuring operating temperatures are strictly regulated even in

ambient temperatures up to 55°C/131°F.*

6).Oil separator

- Innovative filter material removes oil particles from the compressed air while minimizing pressure drop. This results in optimal air quality at the highest efficiency.

7).Inlet valve

- The inlet valve is sized for maximum flow to eliminate any inefficient pressure drops.

- The valve is operated through vacuum and air pressure to offer superior reliability compared to spring operated

inlet valves.

8).Inlet filter

- A heavy duty air intake filter protects the compressor components by removing 99.9% of dirt particles down

to 3 microns.

- The main cooling fan cools the electrical cubicle, ensuring operating temperatures are strictly regulated even in

ambient temperatures up to 55°C/131°F.*

6).Oil separator

- Innovative filter material removes oil particles from the compressed air while minimizing pressure drop. This results in optimal air quality at the highest efficiency.

7).Inlet valve

- The inlet valve is sized for maximum flow to eliminate any inefficient pressure drops.

- The valve is operated through vacuum and air pressure to offer superior reliability compared to spring operated

inlet valves.

8).Inlet filter

- A heavy duty air intake filter protects the compressor components by removing 99.9% of dirt particles down

to 3 microns.

Похожие товары

Заводская поставка 600, белый плавленый глиноземный порошок для полировки стекла

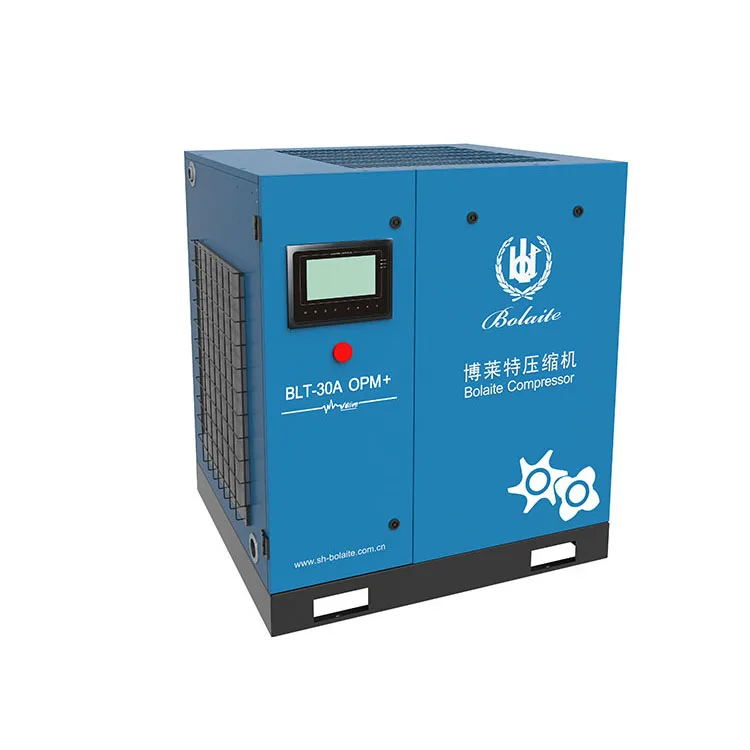

Заводской Магнитный винтовой компрессор с регулируемой скоростью

4 600,00 $ - 5 000,00 $

Дверная лопасть для лифта FAA24390H1 AT120, дверные коньки, запчасти для лифта

29,20 $ - 32,00 $

Запчасти для лифтов, ферматорная дверь, треугольный замок S200

Продолжаем получать новые ролики для лифтов Hitachi 65*15*6202, запчасти для лифтов

2,50 $ - 7,00 $

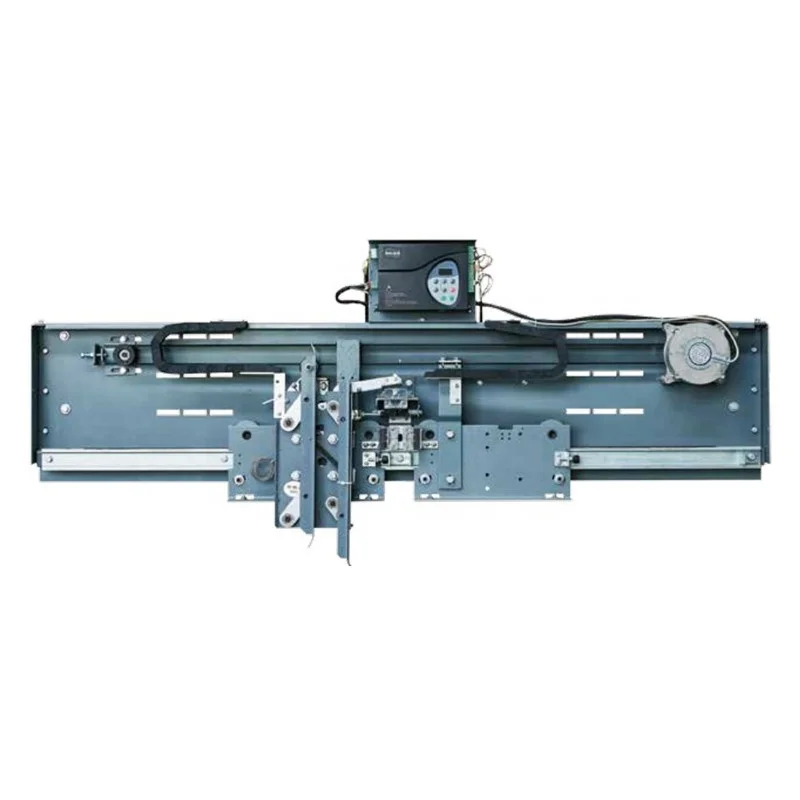

Запчасти для лифтов mitsubishi MJ01, запасные части, дверная система

300,00 $

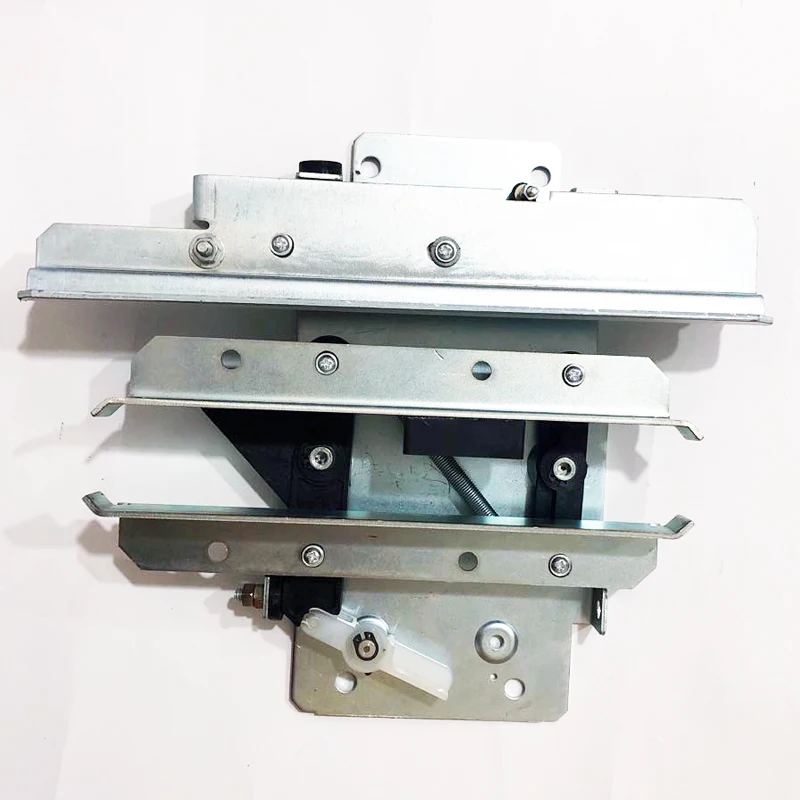

Детали лифта дверного замка PB161

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $