Производители профилей eiti и kinbon из НПВХ для Индии

- Категория: >>>

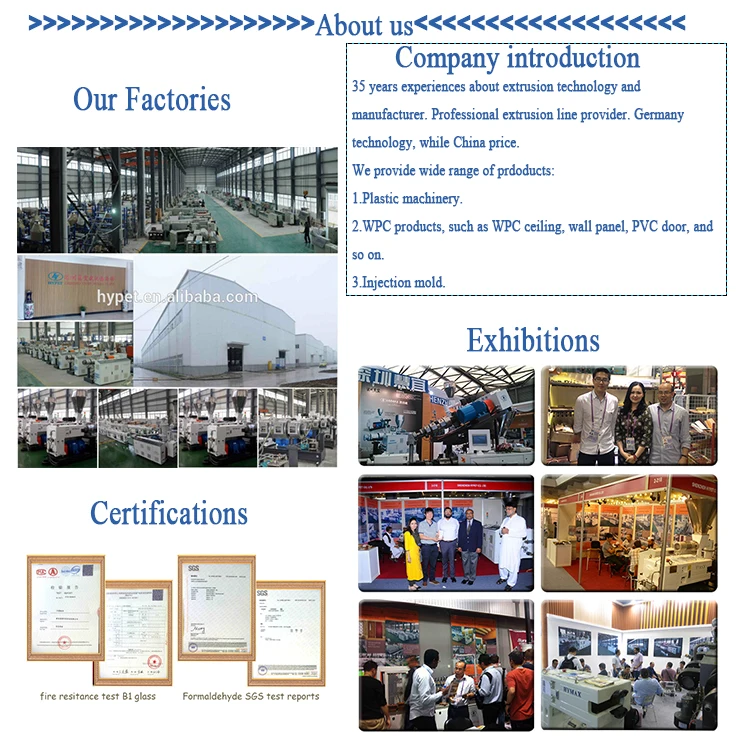

- Поставщик: Shenzhen HYPET Co. Ltd.

Сохранить в закладки 60806257391:

Описание и отзывы

Характеристики

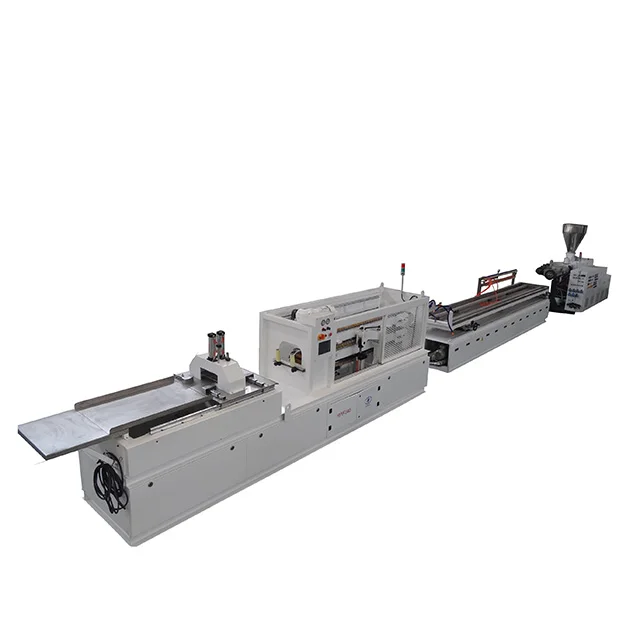

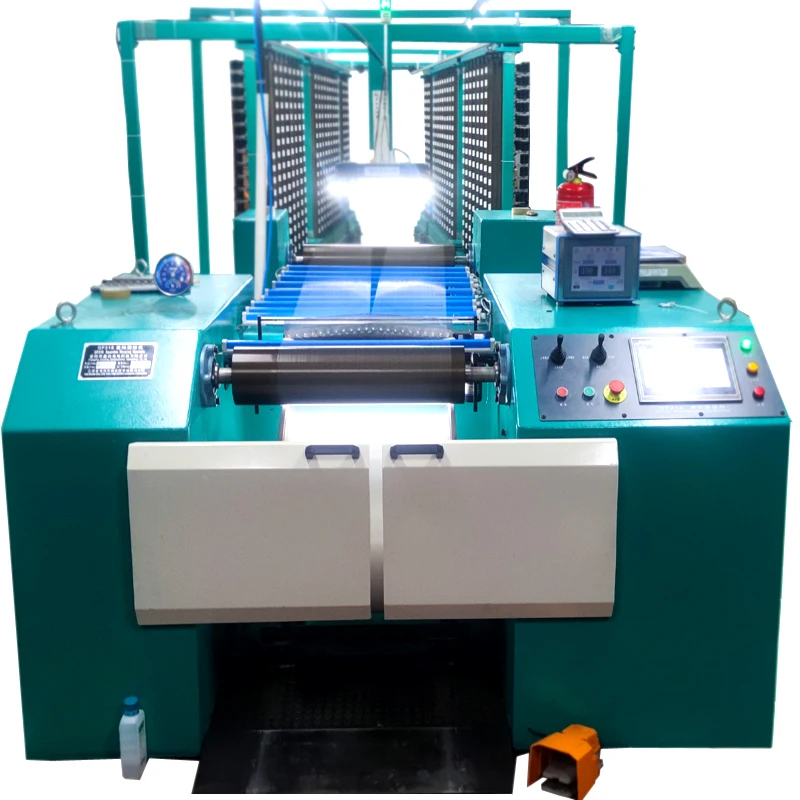

eiti & kinbon upvc profile machine manufacturers for india

HYPET Advantages

New generation gear box to put bearings near to the screws not in the far back;

HYPET Extruder + die device to make the profile more hard & bright;

HYPET barrel in two parts bi-matal, and totally hard alloy ensure more than 3 years; (less than 75 CaCo3)

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

Circumstances condition

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | \t | \t |

| \t | \t | ||

| \t | \t | ||

| \t | \t | \t | \t |

| \t | \t | ||

| \t | \t | ||

| \t | \t | \t | \t |

| \t | \t |

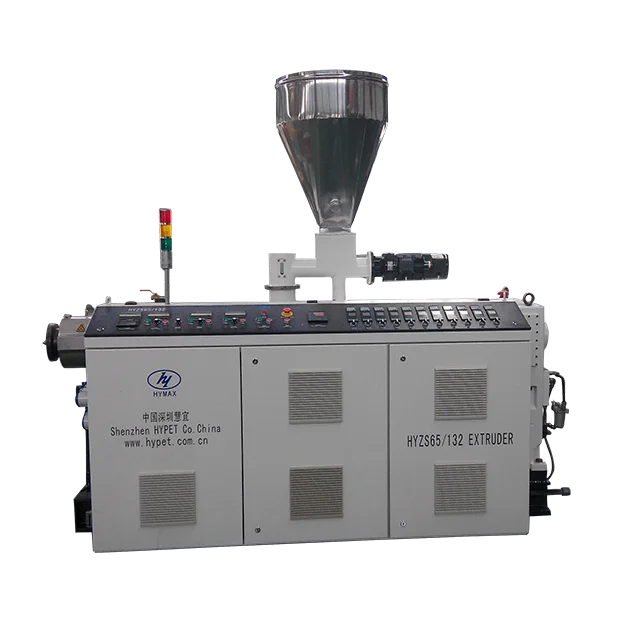

HYZS-65/132H conic twin screw

Barrel is Nitro Alloy with bi-metal in two parts for longer working life.

The harden and ground gear box is made with German technology.| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | \t | \t |

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | \t | \t |

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | \t | \t |

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | \t | \t |

| \t | \t | ||

| \t | \t | \t | \t |

| \t | \t |

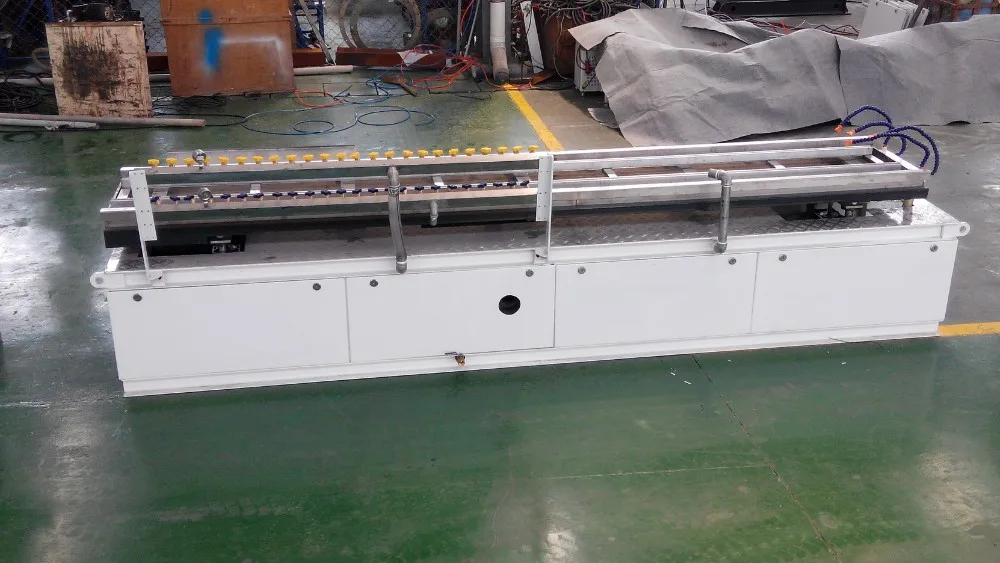

Vacuum table

The vacuum pump is in high quality,

it would be formed by vacuum

Vacuum Calibrator is with integrated leg & platform.

it help making the the form and cooking

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

Haul off & cutting

Consists of top and bottom support which houses chain driven jaws with rubber profile.

Bottom support is fixed one and top support is pneumatically operated

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | \t |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t |

Stack

The tripping chute is made from MS rigid structural steel.

Tilting table is Pneumatically operated.

Integral Stand provided for profile stacking.

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

Похожие товары

Длительный срок службы, производитель ПВХ листов Celuka WPC

Экструдер серии SJSZ с двойным винтом от производителя, Экструзионная линия для ПВХ труб

Аппарат Sokos для автоматической розлива питьевой воды, оборудование для производственной линии/установки/блока

Промышленный кислородный генератор HIROSS, цена, генератор кислорода omron, устройство генерации кислорода

Новый дизайн, двойной конический винтовой экструдер PLC для ПВХ-материала

Высокое J22 Bluetooth совместимым, автомобильный набор, Handsfree, Bluetooth приемник Aux беспроводной Поддержка подключения 2 устройств автомобильный адаптер

Станок для резки мрамора и камня с ЧПУ от производителя

Новые поступления

Новинки товаров от производителей по оптовым ценам