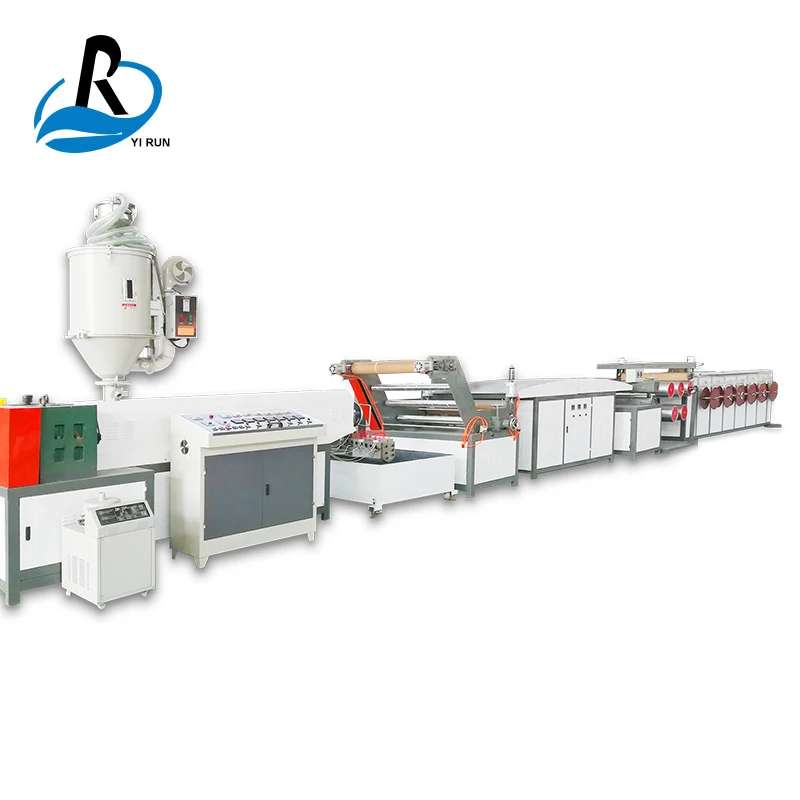

Двухвинтовая Экструзионная линия для пластиковых стаканчиков пищевых контейнеров/лотков/тарелок/мисок машина производства

- Категория: Plastic Extruders >>>

- Поставщик: Guangzhou Sme Plastic Corp.

Сохранить в закладки 60809117664:

Описание и отзывы

Характеристики

APPLICATION AREA

This machine is suitable for producing PET sheet.It extrudes granule to sheet which is used for producing different kind of plastic cups,food containers,trays,dishes,bowls... ...etc.

1st.Main technical parameters

Item | Unit | Specification | Remarks |

Processed material | PET | ||

Thickness of sheet | mm | 0.16~1.6 |

|

Thickness error of sheet | mm | ±0.01 |

|

Form of screw |

| building block system; |

|

Specification of Screw | mm | Ø 70×44 |

|

Effective width of sheet | mm | ≤760 |

|

Hierarchy number | Layer | 1 |

|

Max extrusion capacity | kg/h | 300 |

|

Linear velocity of sheet | m/min | ≤26 |

|

Rated power | kw | 220 | actual use 50% |

Size | L×W×H(mm) | 12980×2510×3800 |

|

2nd.Main device

1, | 70Twin Screw Extruder | one set |

| nominal diameter of screw: Ø70mm machine barrel cooling: water cooling main motor:90Kw alternating current motor frequency converter: KEMRON reduction box: domestic transmission way: straight connecting transmission L/D ratio of screw : 1:40 air outlet : 2, vacuum exhaust heater: front 2 areas are cast copper heaters ,back 2 areas are cast aluminium heaters heating power: 80Kw temperature control way: Temperature control module. PID automatic temperature control screen changer: double column change screen melt metering pump: domestic melt metering pump, 100CC. Drive motor power: 5.5Kw,controlled by AB frequency converter mould head: 800MM, mould mouth has clog. heating power of mould head: 15Kw | |

2, | Tablet compression machine | one set |

| tabletting structure: horizontal tabletting type transmission way: diameter drive independently reduction box and motor: HENGCHI reduction box and frequency converter. motor power: 2.2Kw*3 frequency converter: KEMRON up and down movement: motor-driven forth and back movement: motor-driven specification of tabletting roller: Ø316*900 shaping specification: Ø 420*900 specification of cooling roller: Ø420*900 bearing: Japan NSK gap adjustment: worm gear roller material: alloy steel linear velocity: 26M/MIN | |

3, | roller constant temperature machine (three in one) | one set |

| water pump power: 2.2Kw×3 heating power: 6Kw×3 range of temperature control: normal temperature to 90 degrees temperature control way: Temperature control module. PID automatic temperature control | |

4, | sheet guiding frame | one set |

| sheet guiding roller: aluminium guiding roller, dealt by static balance specification of sheet guiding roller: Ø 80×900 sheet cutting:1 set, combination cutter frame structure,2 pieces of cutter | |

5, | traction machine | one set |

| specification of traction roller: Ø215×900 reduction box:HENGCHI frequency converter: KEMRON transmission way: straight connecting transmission offcut winding device:1 set | |

6, | double-station winding machine | one set |

| winding way: winding of Central inflatable axis winding power: torque motor, torque: 12NM station change: motor-driven winding diameter:800MM | |

7, | control system | one set |

| PLC: Omron touch panel: Waylen | |

1. Payment terms:40% paid for deposit by T/T before production arranged, the balance to be paid before shipment;

2. Delivery time: 90-100 days after receipt of deposit;

3. Guarantee: One year;

We supply you spare parts for 1 year, but the freight will be on buyer’s account;

4. Installation: Our company can send one technician to the buyer’s side for machine installation, test running machine and basic training. If it exceeds one week, the buyer needs to pay US$100 one day for the technician as the salary. The visa and round trip tickets, accommodation will be on the buyer's account;

Delivery Time: It will take within 90-100 days to ship out customer’s goods after get customer’s advance payment.

Похожие товары

Трехслойная стойка для совместной экструзии/ротационная машина для высечки пленки дуя машина

250-350 кг/ч уплотнитель EPS одноступенчатые прядь гранулирования линия

Высокий крутящий момент EPS epa экструзии машины гранулирования пластиковых Двойной Винт Экструдер pe экструдер рецептуры

EPS PS Переработки Отходов Пластмасс гранул машина

Новое условие PP/PE Raffia сплетенная плоская пряжа машина по изготовлению пластика

Pe pp пластик прядильная машина/pp пряжа делая производственную линию машины

Гарантия качества pp/pe пластиковой плоской пряжи рисунок решений экструзионные машины

Новые поступления

Новинки товаров от производителей по оптовым ценам