MX MSF180 легко собирающийся студийный фото металлических строительных материалов по индивидуальному или стандартному дизайну ковер стеллаж для выставки товаров

- Категория: >>>

- Поставщик: Zhongshan Meixiang Display Products Co. Ltd.

Сохранить в закладки 60809883840:

Описание и отзывы

Характеристики

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | |||

| \t | |||

| \t | |||

| \t | |||

| \t | |||

| \t | |||

| \t |

ABOUT MX-DISPLAY

Zhongshan MX-Display Factory was founded in 2004.Our company is a professional display stand and display rack factory with R&D team,top graphic designers and best sellers. MX Factory have the most advanced production facilities and professional equipment.We have 11 years experienced,strong teamwork spirit R&D,production and sales team. we have long-team partnership with clients to win the good reputation.We constantly improve the mode of operation and management system, strengthen R&D team so we can independently produce and design different kinds of display product.

Based on the spirit of "Quality stabilization, Price reasonable, First-class services, Integrity" to provide the best display products for the world. Dream from Meixiang to China to the World!

Powerful Design Team

1. We help each of our customers designed over 200 customized drawings for display,also we can design, dimensions, color and logo for our models.

2. We can provide different kinds of 3D drawings for display model,like 3D Max, Solidwork, CorelDraw and CAD etc.

CAD Drawing - completely details for display,send to customer to confirm before sample and production.

3D Max Drawing - for customer better to check the apperance of display 3D view.

Solidwork Drawing - for customer better to know the structure of display and modify rapidly.

Strong Wood Workshop

Full-Automatic Large Cutting Board Machine

4 Semi-Automatic Cutting Board Machines

Full-Automatic Edge Banding Machine

Full-Automatic Pressing Board Machine

2 Semi-Automatic Punching Machines

Large Laser Engraving Machine

Wood Painting Workshop

We have 4 painting rooms,sweeping room and big drying room,floor over 1000 square meter,30 painting workers,when wood components semi-fninsh,send to sweeping room ready to painting.

Ready Room For Sweeping Process

Sweeping Room

Drying Room After Painting

Drying Room After Painting

Powerful Metal Workshop

We have over 800 square meter,30 workers in metal workshop finish all kinds of metal components process,with all kinds of work machines,like cutting metal plate & metal pipe,bending,punching,laser engraving &welded.

3 Metal Plate Cutting Machines

4 Metal Plate Bending Machines

8 Metal Plate Punching Machines

4 Metal Pipe Cutting Machines

Completely Powder Coated Workshop

We have big rust pickling room, 2 powder coated room and drying system, include over 20 workers,paint all kinds of color and textures,like retro, frosting, old and mxiture etc.

Powder Coated Rooms

Transport Line And Drying System

| \t | |||

| \t | |||

| \t | \t | ||

| \t | \t | ||

| \t | |||

| \t | \t | ||

| \t | \t | ||

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How long is your delivery time?

A: Generally it is 25~30 days for mass production, 7~10 days for sample production; if quantity over 3000pcs,maybe need 30~40 days to finish.

Q: Do you provide samples ?

A: Yes, we could offer the sample for 2~3 times of unit price,do not pay the cost of freight.

A: Production term: 30% T/T in advance ,balance before shippment.

Sample term: full payment in advance.

If you have another question, pls feel free to contact us as below:

Похожие товары

Уличная лампа Goldisgood, нагреватель, галогенная лампа, Коротковолновая инфракрасная нагревательная лампа для машины

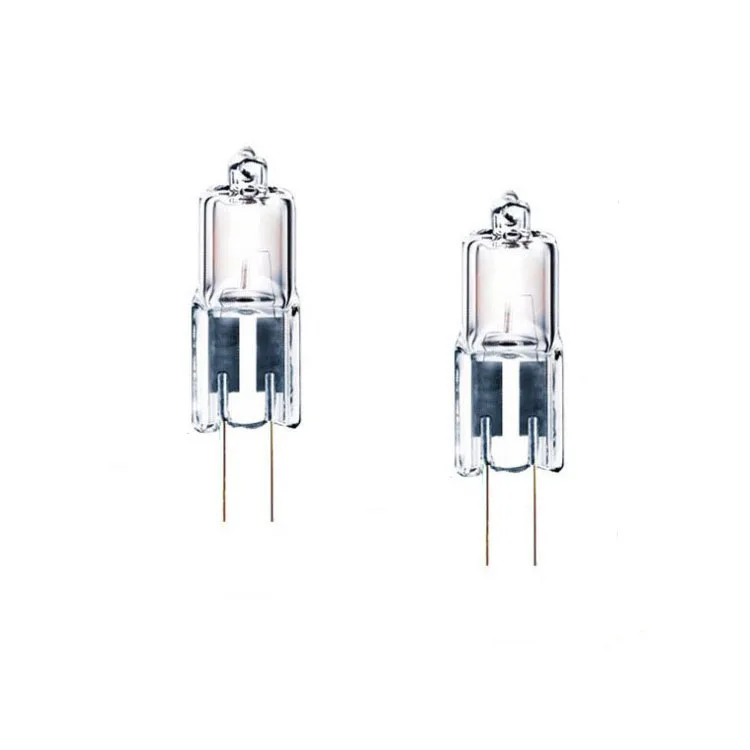

Галогенная лампа AR111 12V низшее напряжение 50 Вт 75 Вт 12В G53 8 градусов 24 градусов угол луча прожектора AR111 , HAL-AR

Лучшая низковольтная лампа 42 Вт 42 Вт, высокая люменов, галогенная лампа, лампа 42 Вт, галогенная лампа

Купить аттракционы для парка развлечений

Интеллект дети играют мозг умные головоломки игрушки развивающие игры Кубики магии для продажи

Горячая Распродажа авто запчасти двигателя 11183-78010 SO5C Головка блока цилиндров для грузовика Volvo 5.3L L4 16V

10PCS packed Spain Football World Cup pin the foot ball Broochthe bags hats decoration brooch Badges

Новые поступления

Новинки товаров от производителей по оптовым ценам