0215 микронизированный полиэтиленовый воск

- Категория: >>>

- Поставщик: Nanjing Tianshi New Material Technology Co. Ltd.

Сохранить в закладки 60812650506:

Описание и отзывы

Характеристики

0215 Micronized Polyethylene Wax

Micronized PE Wax

Chemical Composition

Polyethylene Wax

Technical Parameters

Nature of the Product | PEW-0215 | |

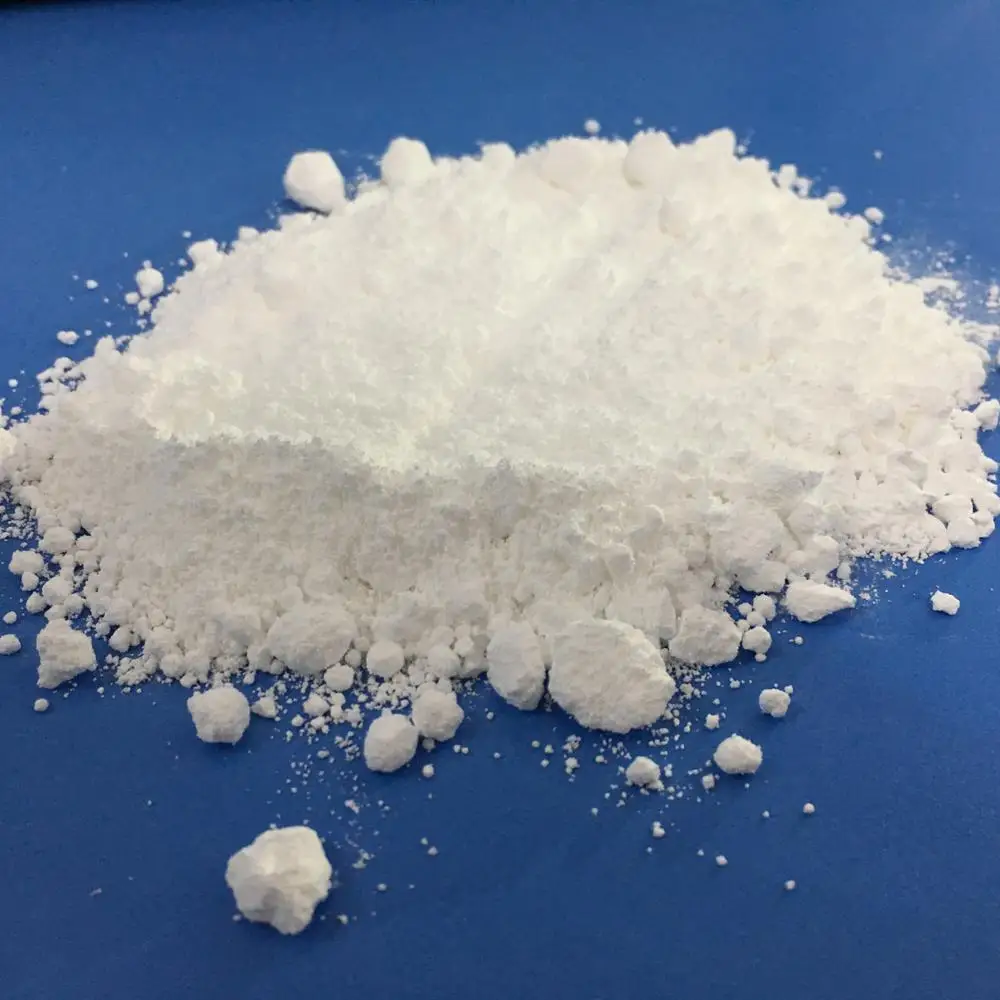

Appearance |

| White Powder |

Particle Size μm |

|

|

| Dv50 | 7 |

| Dv90 | 18 |

Melting Point ℃ |

| 110 |

Characteristics and Purposes

Ø Micronized wax which is suitable for solvent-based flexo-printing ink, as well as solvent-based gravure printing ink, can improve the abrasion resistance, and scratch resistance when used in solvent-based ink. PEW-0215 can reduce the coefficient of friction in different kinds of inks. What’s more, PEW-0215 has good adaptability in benzene soluble ink, alcohol soluble ink and resin soluble ink.

Ø In offset ink, PEW-0215 can obviously increase the abrasion resistance of layer, and the additive amount is normally at 0.5-1%.

Ø PEW-0215 can improve the abrasion resistance, scratch resistance in varieties of coatings. Can also be used in plastics coatings, coil coatings and other fields as well as solvent-based ink.

Ø Can be used in powder coating, to improve the hardness and scratch resistance at the additive amount of 0.3%, and will not smoke under 180℃ baking.

Additive amount and Usage

Ø In varieties of systems, the additional amount of the micronized wax is generally between 0.5 to 3%.

Ø Usually by a direct high-speed stirring, it can disperse in solvent-based coatings and printing inks.

Ø It can be added by using varieties of grinding machines, high-shear dispersing device, and grind mill. Should pay attention to the temperature control.

Ø Can make wax slurry with the wax at 20-30%, and add it into the systems when needed, by which the wax dispersion time can be saved.

Packaging and Storage

Ø Paper-plastic bag, net weight: 20 kg / bag.

Ø This product is non-dangerous goods. Please store it away from ignition sources and strong oxidants.

Похожие товары

Ортопедическая ручная шина с большим пальцем

Фабричная цена текстиль жидкий воск эмульсия окисленный полиэтиленовый воск эмульсия HT-T21

Химическая устойчивость, окисленный полиэтиленовый воск для резины

24 дюймов FHD 2k 144 Гц 1 мс игровые мониторы

Производители 5-футовых комнатных и уличных прыжков для малышей, Круглые Батуты с крышей палатки для батута

Полиэтиленовое сырье высокой плотности для выдувного формования HDPE 5502 натуральные гранулы HDPE от китайского производителя

SM322 электронные сигареты с цифровым выходом модуль 8-ходовой переключатель реле 5A с резистивно-емкостной фильтр Защита от перенапряжения 6ES7 322-5HF00-0AB0 S7-300 ПЛК

Новые поступления

Новинки товаров от производителей по оптовым ценам